Machine base regulating and lock-fixing device of wood planer

The technology of a locking device and a planing machine is applied in the direction of wood processing appliances, processing machines for manufacturing flat surfaces, manufacturing tools, etc., and can solve the problems of unreliable positioning, influence of clamping effect, hand hitting the top of the machine, etc. Achieve the effect of improving planing quality, adjusting height and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

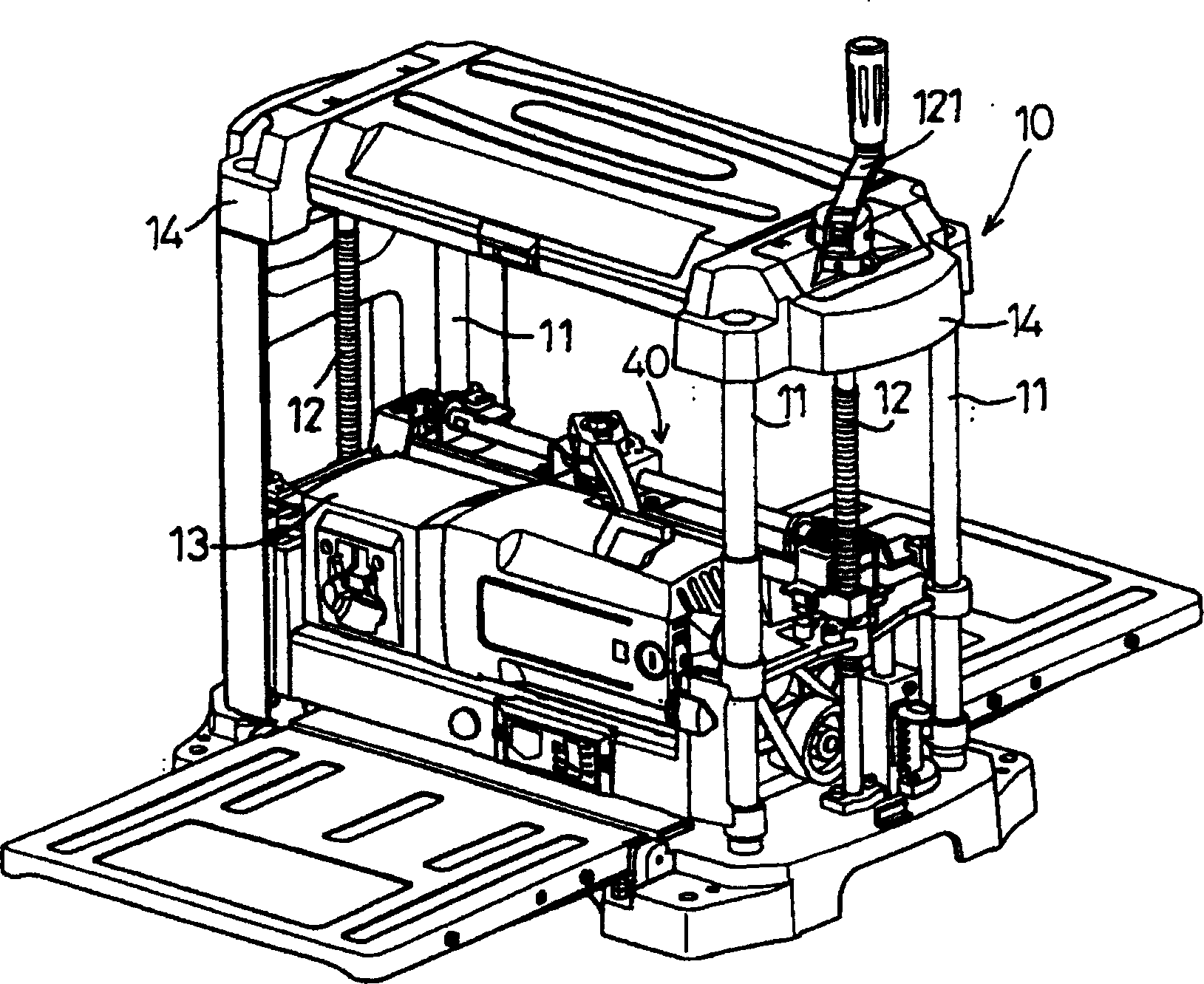

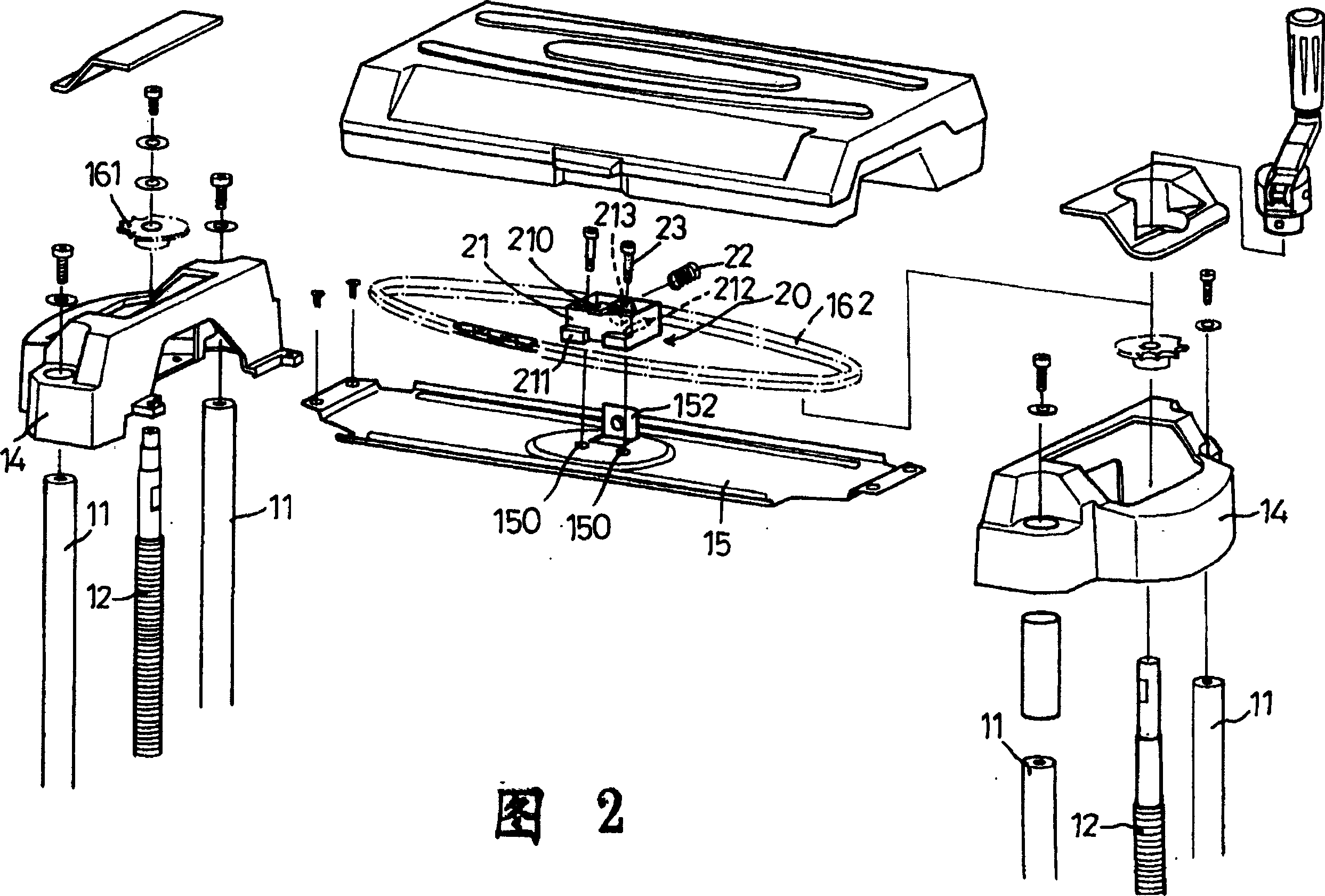

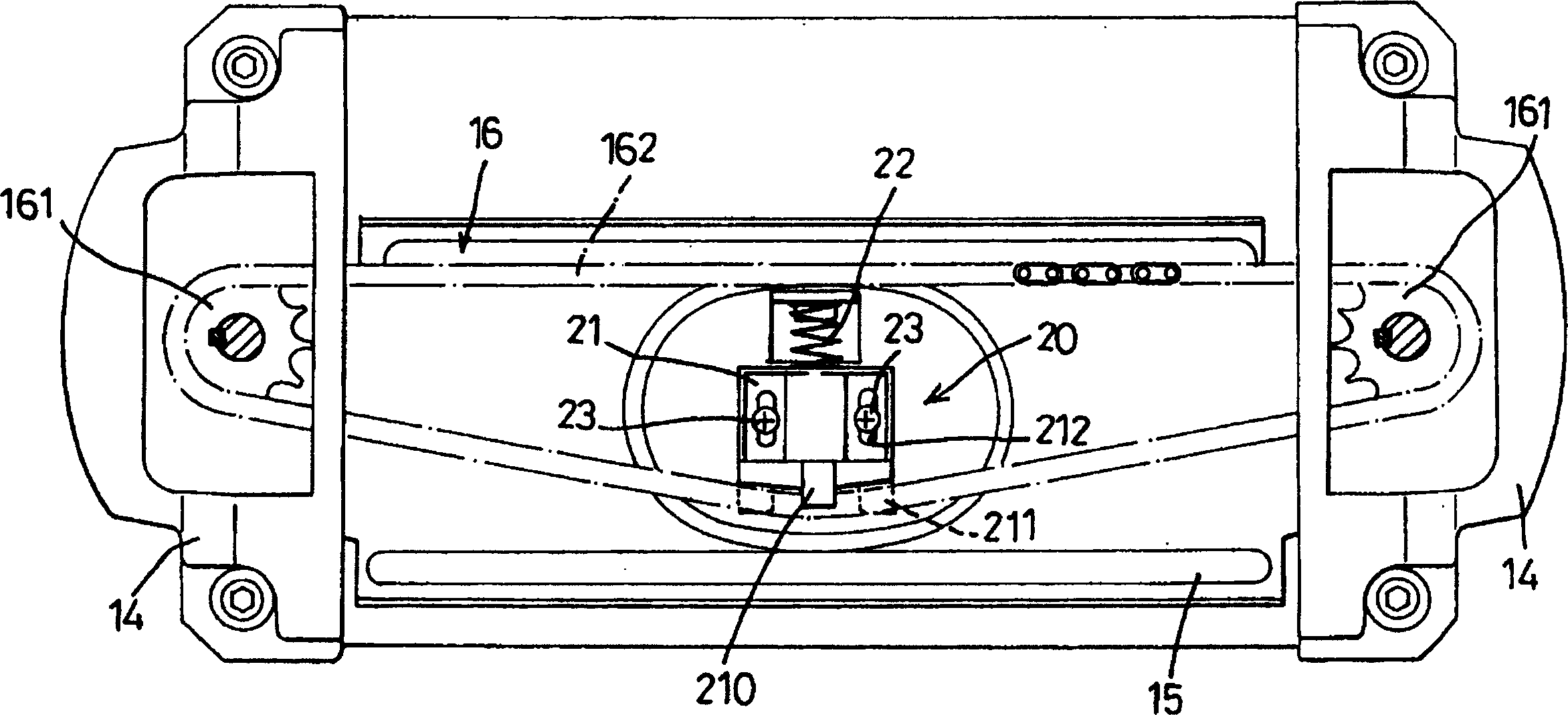

[0025] see figure 1 , 2, the base adjustment and locking device of the woodworking planer of the present invention includes a tensioning device 20 arranged on the top of the machine table to tighten the chain of the transmission device and a tensioning device 20 arranged on the top surface of the base 13 for fixing The locking device 40 of the machine base 13, and the configuration of the woodworking planer 10 is roughly the same as the foregoing, that is, the four corners of the base of the planer 10 are provided with upwardly extending guide posts 11, and the two guide posts 11 are One group, a lead screw 12 is arranged between the guide posts 11 in groups, and the peripheral edge of the machine base 13 with planers assembled at the bottom can pass through the guide posts 11, and be threadedly combined with the lead screws 12, when rotating and assembled on The handle 121 on the top of one of the lead screws 12 can make the two lead screws 12 rotate synchronously, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com