Method of integrated dust removal and desulfur of smoke and its equipment

A technology of flue gas and desulfurization agent, which is applied in the field of flue gas purification, can solve problems such as the difficulty in realizing the coordinated operation of the desulfurization system and the dust removal system, the difficulty in ensuring the dust removal efficiency, and the low capture rate of fine particles, so as to achieve compliance with standards and clean emissions, resistance Small, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The method of the present invention has been described in the technical content of this document, and the scheme is completely the same, so no more details are given.

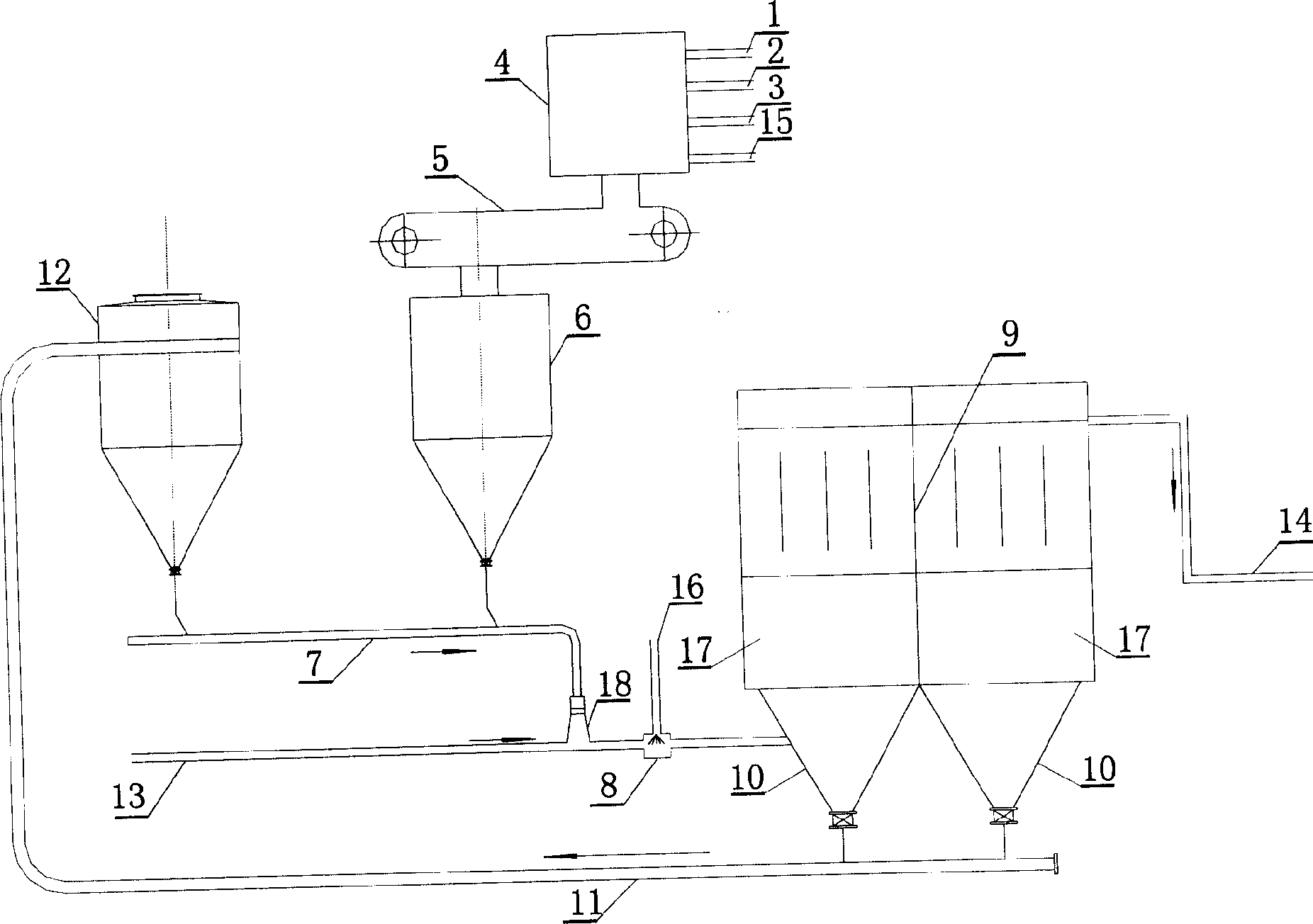

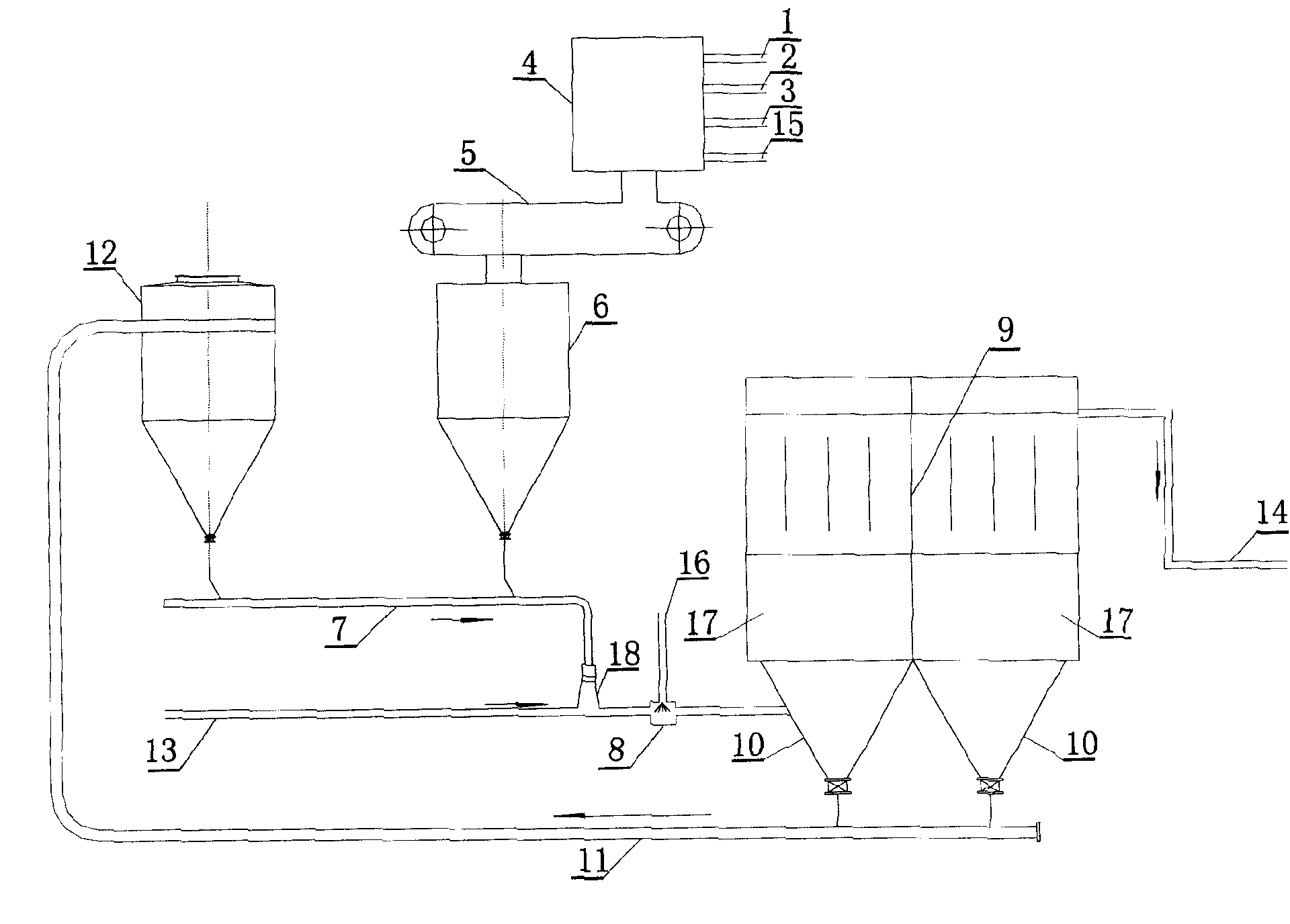

[0012] Referring to the accompanying drawings, the device implementing the inventive method comprises a mixing granulator 4, a belt conveyor 5, a composite bin 6, a circulating ash bin 12, a bag filter 9 and a pre-reaction bin 17 and an ash bin 10 connected to the lower part thereof, Among them, the mixing granulator 4 is provided with a catalyst inlet 1, a desulfurizing agent inlet 2, a water-holding agent inlet 3 and a high-temperature steam inlet 15, and the opening end of the bottom of the mixing granulator 4 corresponds to the tail end of the belt conveyor 5, and the top of the belt conveyor 5 corresponds to the tail end of the belt conveyor 5. The position of the entrance of the compound bin 6 is corresponding, the bottom opening of the compound bin 6 and the circulating ash bin 12 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com