Compliant assembly system and method integrating 3D vision and contact force analysis

An assembly method and three-dimensional vision technology, applied in the direction of program-controlled manipulators, manufacturing tools, manipulators, etc., can solve problems such as wasting time, and achieve the effect of achieving flexibility and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

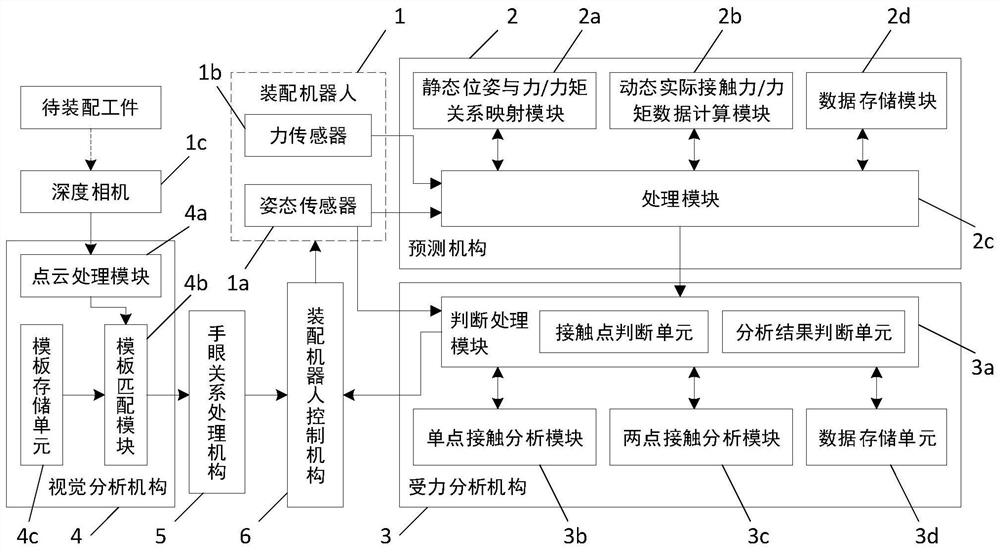

[0052] A compliant assembly system that integrates 3D vision and contact force analysis, such as figure 1 As shown, it includes an assembly robot 1 and an assembly robot control mechanism 6, the assembly end of the assembly robot 1 is provided with an attitude sensor 1a and a force sensor 1b, and a depth camera 1c is provided in the assembly scene, preferably at the assembly end of the assembly robot 1 superior;

[0053] The system also includes a prediction mechanism 2, a force analysis mechanism 3, a visual analysis mechanism 4, and a hand-eye relationship processing mechanism 5. The data input end group of the prediction mechanism 2 is connected to the output end of the posture sensor 1a and the output end of the force sensor 1b, so The data output end group of the prediction mechanism 2 is connected to the data input end group of the force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com