Application method of outer lead pin joining backfold welding heat insulating material

A technology of heat insulation materials and external pins, which is applied in the direction of assembling printed circuits and metal processing of electrical components, and can solve problems such as damage, poor heat resistance, and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

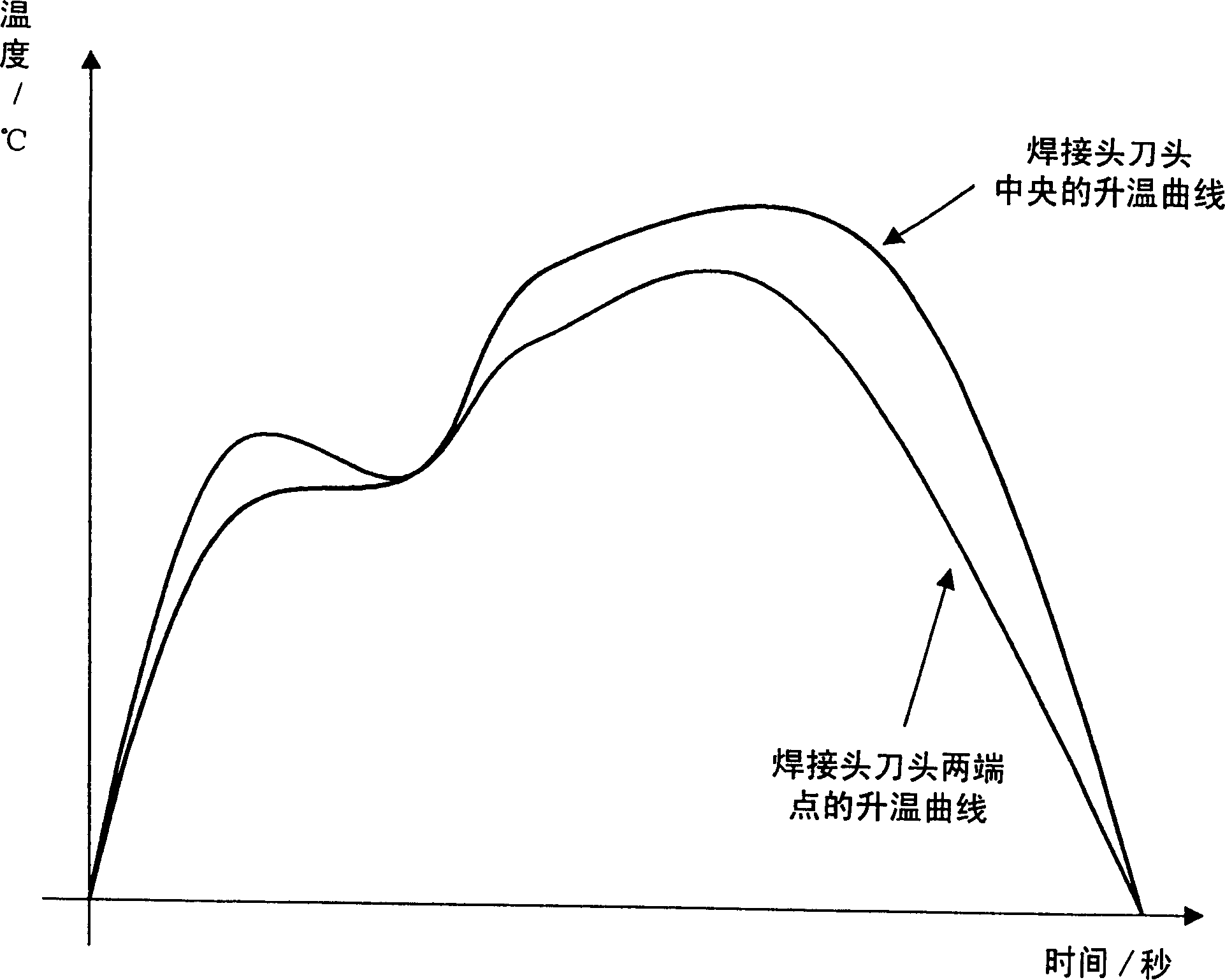

[0026] Please refer to Fig. 1, the method for using the external pins combined with reflexed welding heat insulation materials provided by the present invention mainly includes: a welding joint 1, a heat insulation material 2, an electronic component 3, a circuit substrate 4, the The circuit board 4 is used for the insertion of the electronic components 3. The heat insulating material 2 is composed of a printed circuit board (PCB) material 20 and a metal sheet 21, which provides a conduction process for effectively blocking and dissipating heat sources, so as to improve the circuit own yield.

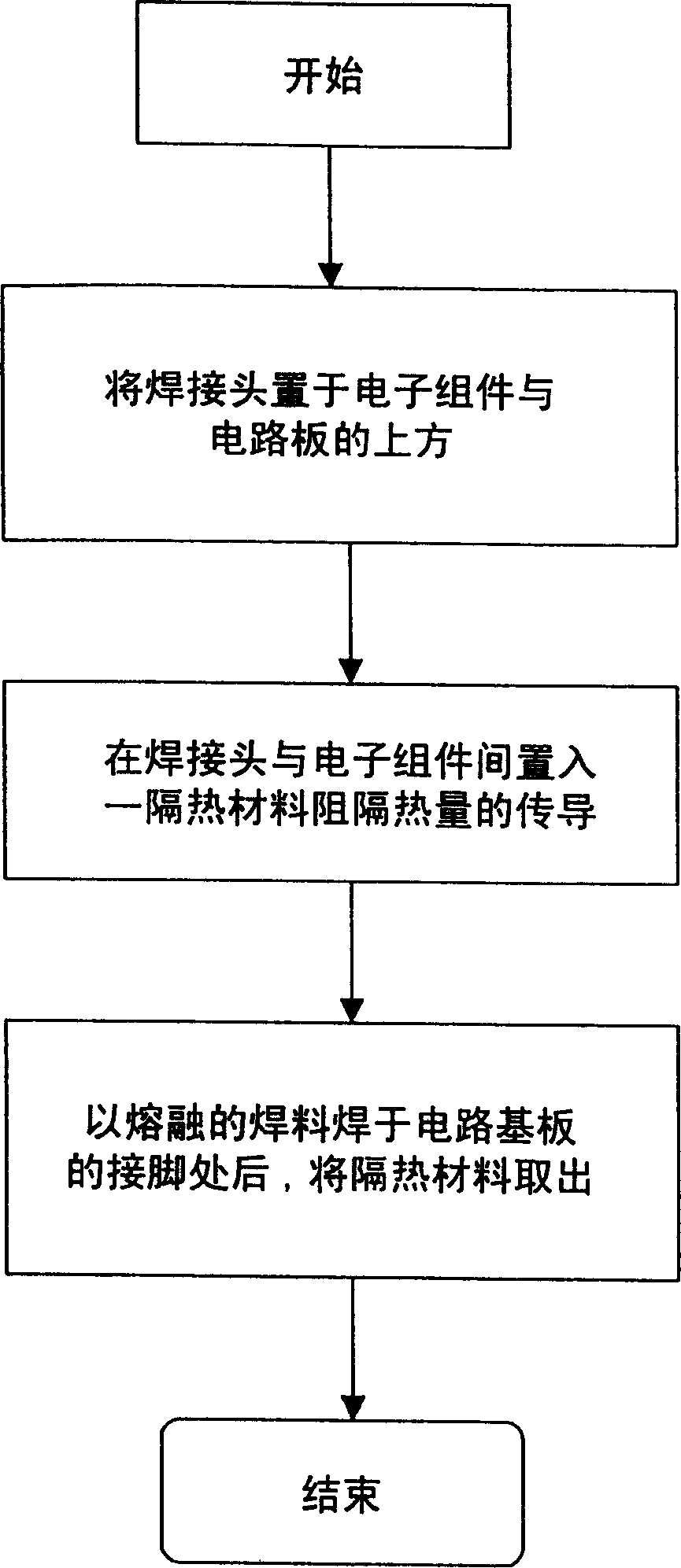

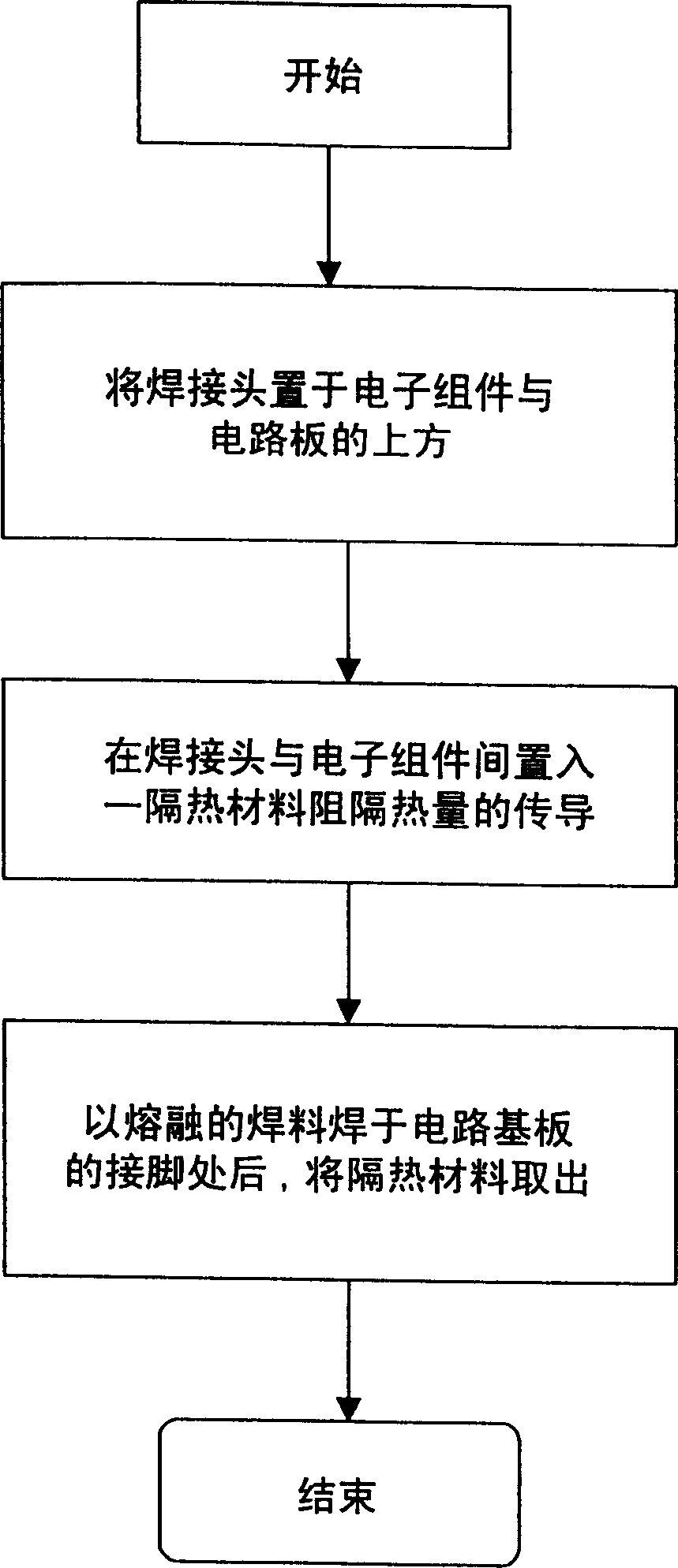

[0027] see figure 2 , Figure 5 , the aforementioned method of using external pins in combination with reflexed welding heat insulation materials is to move a welding head 1 to a pre-welded circuit substrate 4 and electronic components 3 such as: EL (Electo Luminescence electroluminescence) or LCD (liquid crystal) Display) and other superimposed pins 40, place the printed circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com