Metal cutting tool

A metal cutting and tool technology, applied in metal processing equipment, manufacturing tools, milling cutting inserts, etc., to achieve the effect of improving metal cutting efficiency and simplifying design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

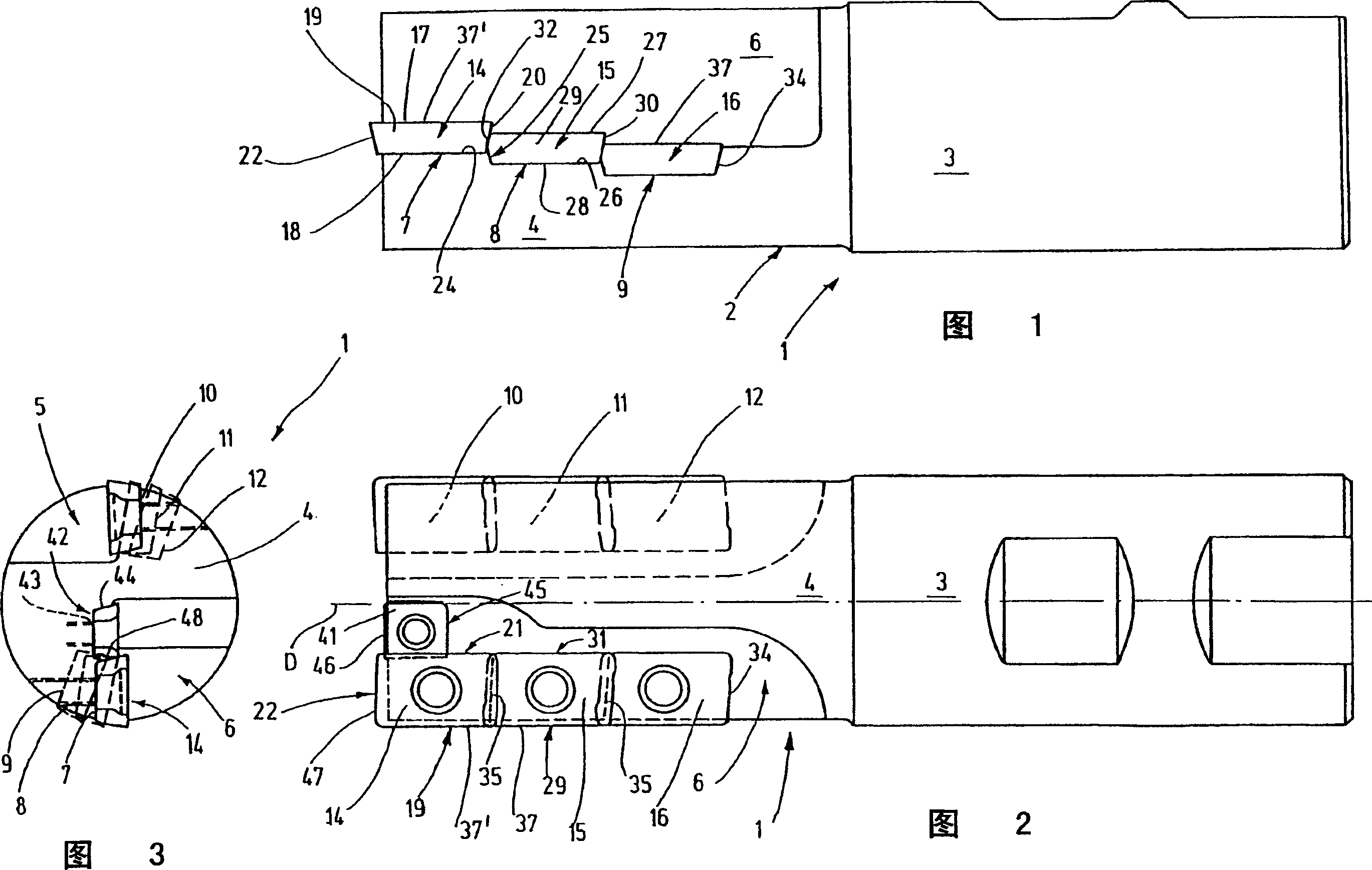

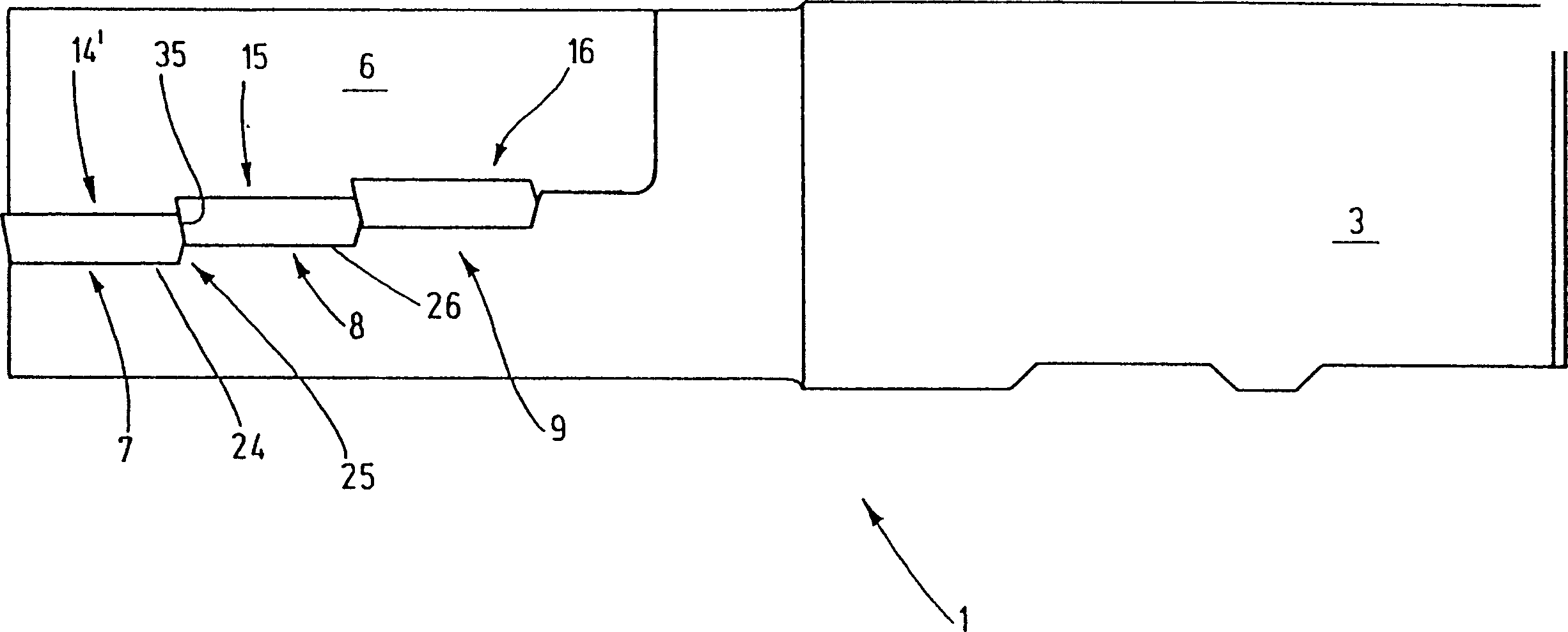

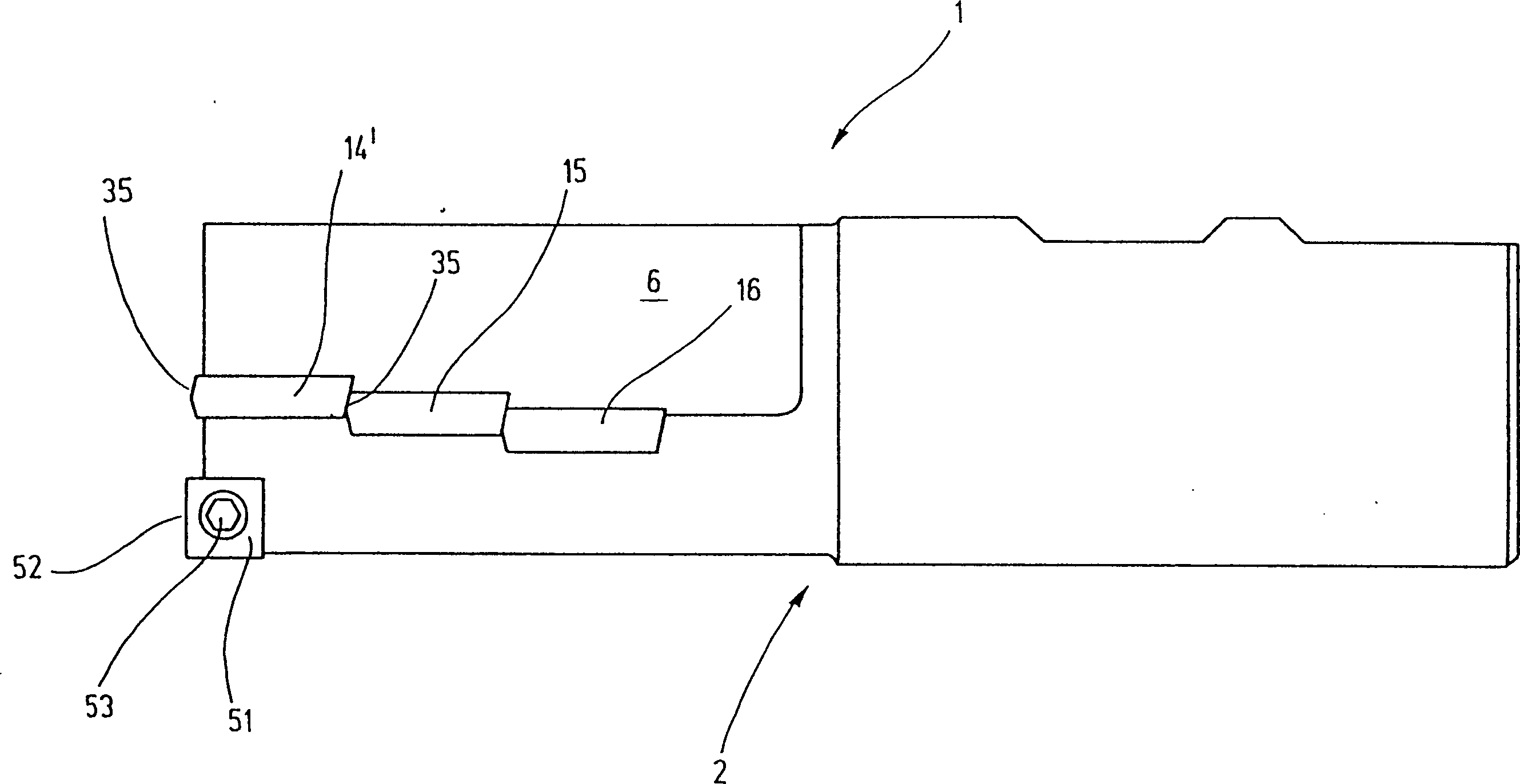

[0025] As shown in FIG. 1 , a metal cutting tool 1 has a tool body 2 with a clamping element 3 and a cutting disk support portion 4 . The support part is based on a substantially cylindrical base and has several chip flutes, for example two chip flutes 5 , 6 in the exemplary embodiment, which can be seen in FIG. 3 . Each chip flute 5 , 6 is an axially extending groove in which several disk seats 7 , 8 , 9 or 10 , 11 , 12 are arranged.

[0026] The chip flutes 5 , 6 or their disc seats 7 , 8 , 9 or 10 , 11 , 12 are identical and are preferably arranged symmetrically with respect to the axis of rotation D of the tool body 2 . Therefore, the following description of disc bases 7 , 8 , 9 also applies to disc bases 10 , 11 , 12 .

[0027] Disc holders 7 , 8 , 9 serve to hold cutting discs 14 , 15 , 16 . These square or rectangular or parallelogram cutting discs each have an end face 17, a base 18 and several transverse surfaces 19, 20, 21, 22 or 29, 30, 31, 32 (see FIGS. 1 and 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com