Layer combined laser crystal

A technology combining lasers and laser crystals, applied in lasers, laser parts, phonon exciters, etc., can solve the problem of particle number inversion difficulty, limit laser power, etc., to improve heat dissipation efficiency, enhance heat dissipation effect, and increase thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

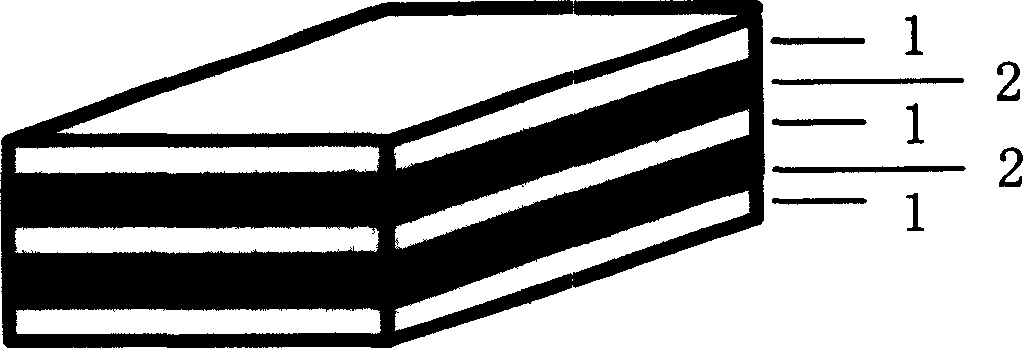

[0019] according to figure 2 A layered composite laser crystal of the present invention consisting of 5 heat-dissipating substances and 4 laser crystals is made. Heat dissipation material 1 is white YAG, whose size is φ5mm×thickness 2mm thin slice; heat dissipation material 3 is white YAG, whose size is φ5mm×thickness 1mm thin slice; laser crystal 2 is Nd:YAG with Nd ion doping concentration of 1.1%. , a sheet with a size of φ5mm×thickness 1.5mm; heat dissipation material 1 and laser crystal 2 are cross-stacked and optically glued together as shown in the figure, and double anti-reflection coatings of 808nm and 946nm are coated on the upper and lower ends of the layered combined laser crystal.

[0020] The layered composite laser crystal is used in a resonant cavity that outputs 946nm, and when the pump light pumps the new layered composite laser crystal from the front, it can output high-power 946nm laser.

Embodiment 2

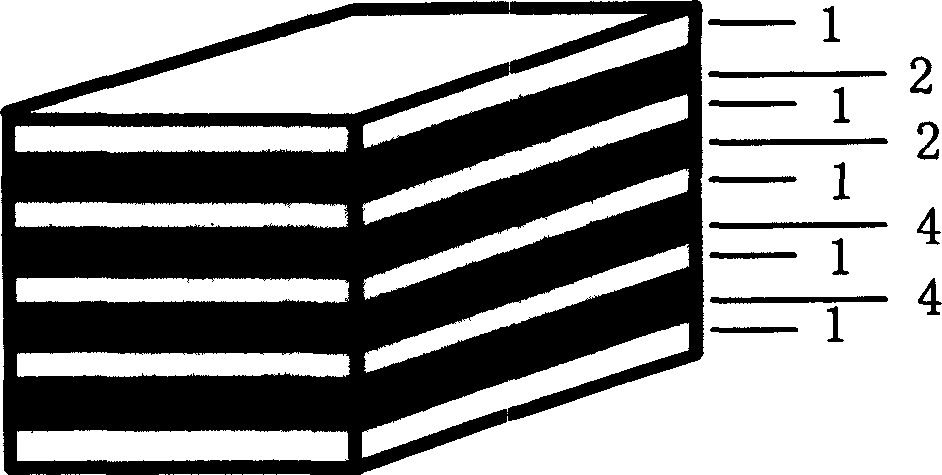

[0022] according to image 3 Make a layered combined laser crystal, including 5 pieces of heat dissipation material 1 using white YAG, whose size is φ5mm×1mm thick; 2 pieces of laser crystal 2 choose Nd:YAG with Nd ion doping concentration of 1.0%, and its size is φ5mm× Thickness 1mm; 2 pieces of laser crystal 4 choose Nd:YVO with Nd ion doping concentration of 0.5% 4 , the size is φ5mm×thickness 1mm laser crystal sheet; heat dissipation material 1 and laser crystal 2 and 4 are optically glued together as shown in the figure, and the two ends of the layered combination laser crystal are coated with 808nm, 914nm and 946nm anti-reflection coatings.

[0023] The layered combination laser crystal is used in a resonant cavity that outputs 914nm and 946nm, and when the pump light pumps the new layered combination laser crystal from the front, it can simultaneously output 914nm and 946nm lasers.

Embodiment 3

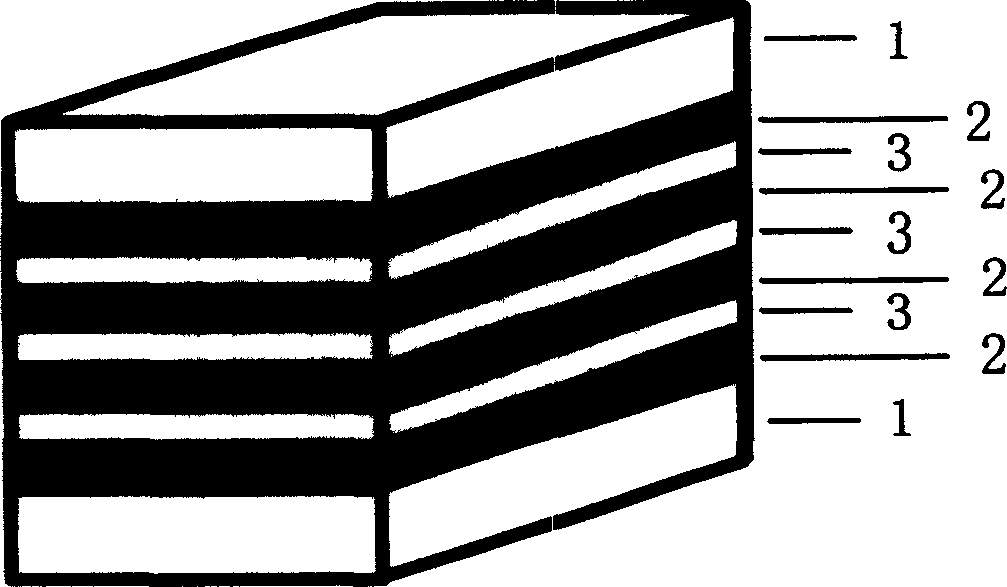

[0025] according to Figure 4 Make a layered combined laser crystal, heat dissipation material 1 is fused silica, its size is φ5mm×thickness 1mm; laser crystal 2 is Yb:YAG with Yb ion doping concentration of 13%, its size is φ5mm×thickness 1mm; Substance 1 and laser crystal 2 are optically glued together as shown in the figure, and the two ends of the layered composite laser crystal are coated with 940nm and 1030nm double anti-reflection coatings.

[0026] The layered composite laser crystal is used in a resonant cavity that outputs 1030nm, and when the pump light pumps the new layered composite laser crystal from the front, it can output high-power 1030nm laser.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com