Gas protection process for feeding alloy wire into molten steel and its equipment

A gas protection device and gas protection technology are applied in the alloying of molten steel in iron and steel plants, the refining process and its devices, which can solve the problems of increased inclusions, low alloy recovery rate, and oxidation of molten steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

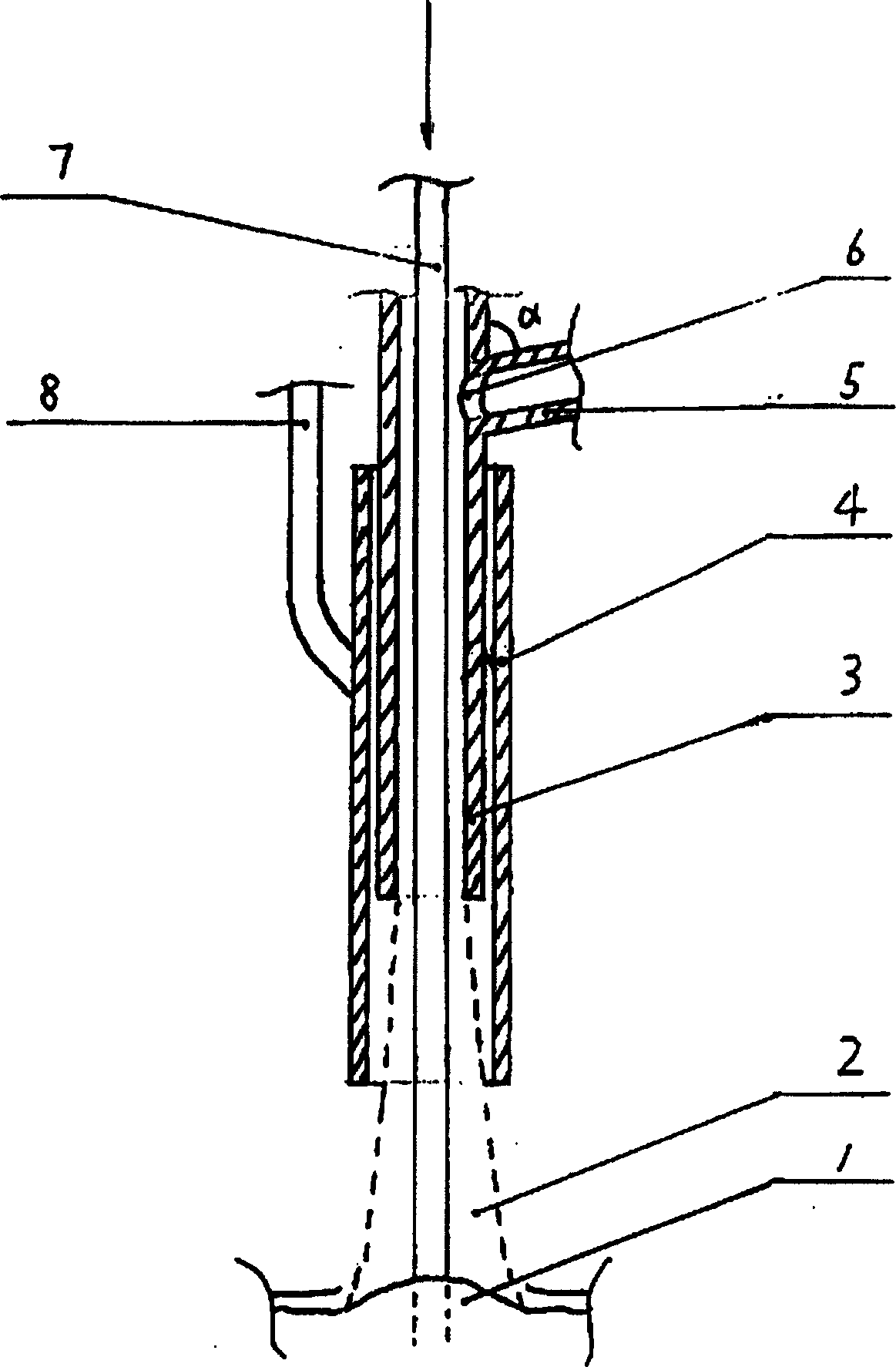

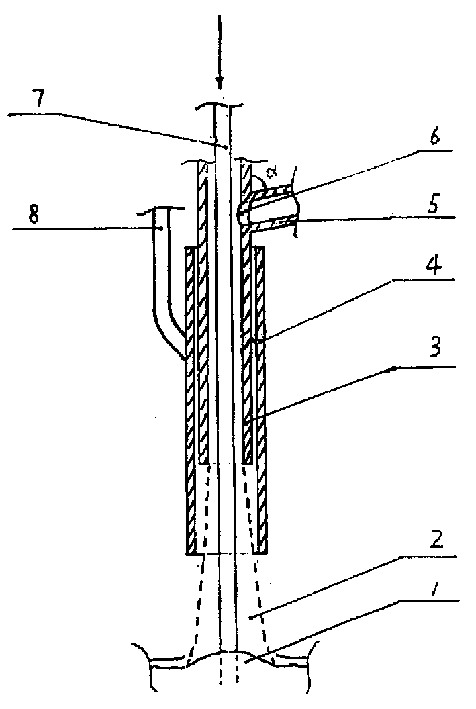

[0007] The alloy wire (7) enters the molten steel (1) through the conduit (3), (4) along the direction of the arrow, and the protective gas is filled into the conduit (3), (4) from the gas supply pipe (5) and the through hole (6). , and rush out from the wire conduits (3), (4) to form a protected area (2) to protect a section of the alloy wire (7) and molten steel (1). The conduit (4) is lifted or lowered by the lifting arm (8). The included angle α is an acute angle, so as to reduce the shielding gas rushing out from the wire inlet end of the conduit (3). According to the user's intention, the wire conduit (4) can be made into a bell mouth shape.

[0008] The process and device proposed by the invention can reduce the degree of oxidation of alloy wires, especially easily oxidized alloy wires such as calcium, magnesium, titanium, aluminum and their composites, and improve the metallurgical effect.

[0009] In the production of steel types such as 45, 08Al, Q345D, 16MnR, AH36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com