Low-speed motor

A low-speed motor and generator technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problem that the motor is not suitable for special purposes, and achieve the effect of reduced cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

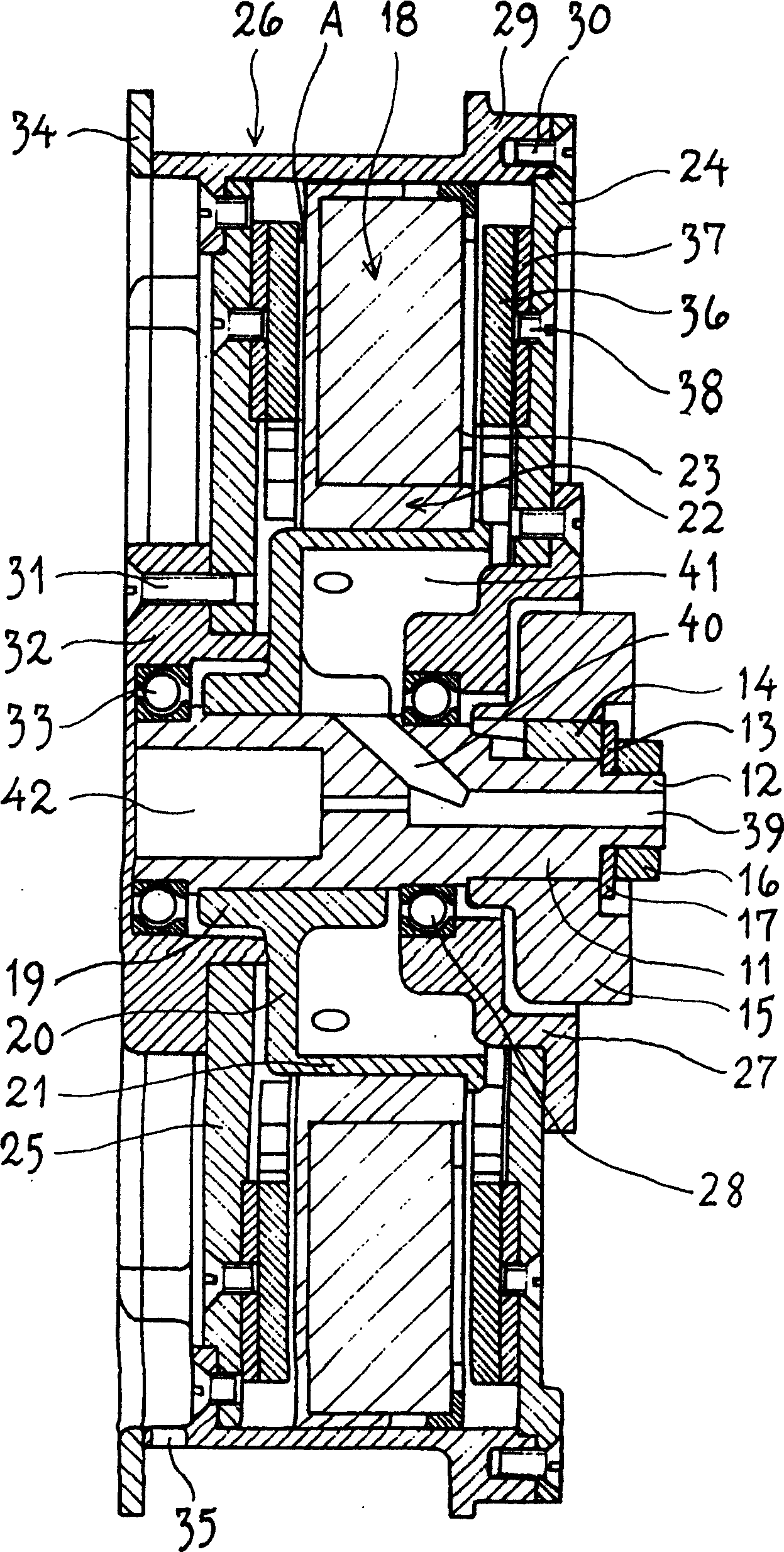

[0030] figure 1 The motor shown is one suitable for powering vehicles such as wheelchairs, trucks and other conveyors on wheels. The motor can be used periodically as a generator, eg for braking. The electric motor comprises a shaft 11 which is supported on the vehicle by a carrying arm 15 or corresponding bracket through an inner tapering end 12 with a keyway 13 and a key 14 . Locking is provided by a nut 16 with a washer 17 .

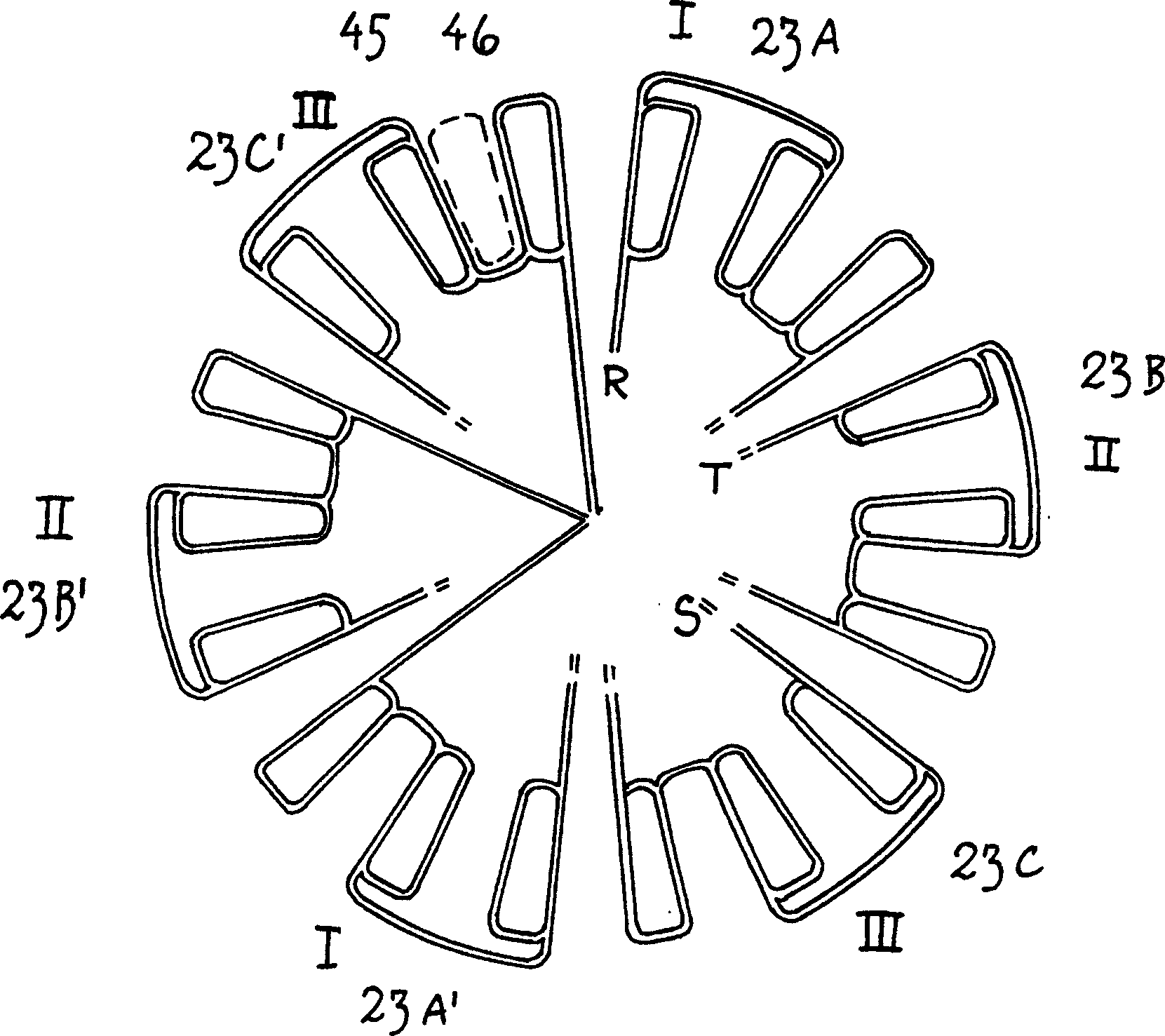

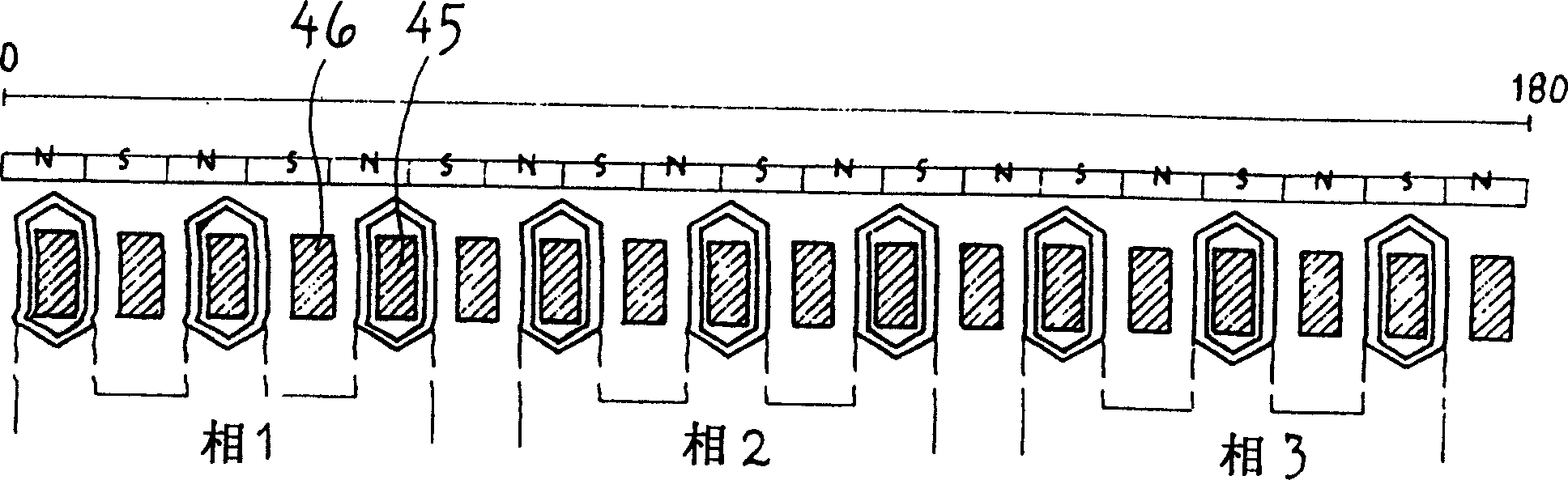

[0031] The shaft 11 has a stator part 18 and a rotating part, both of which are constructed of several parts. The stator part 18 comprises a hub 19 converging on the shaft with a radially central flange 20 which enters and carries a cylindrical stator bushing 21 which extends to the carrier arm 15, but in the axial direction of the carrier arm. end in distance. The stator bushing 21 has a plastic component 22 embedded with coils 23 scattered around it. In the illustrated embodiment, there are 18 spaced apart stator coils 23 . The stator coils, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com