Method and device for cutting yarn on a textile machine

A textile machine and yarn technology, applied in the field of yarn cutting and installation on a textile machine, can solve problems such as excessive blade wear and tear, and achieve the effect of preventing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

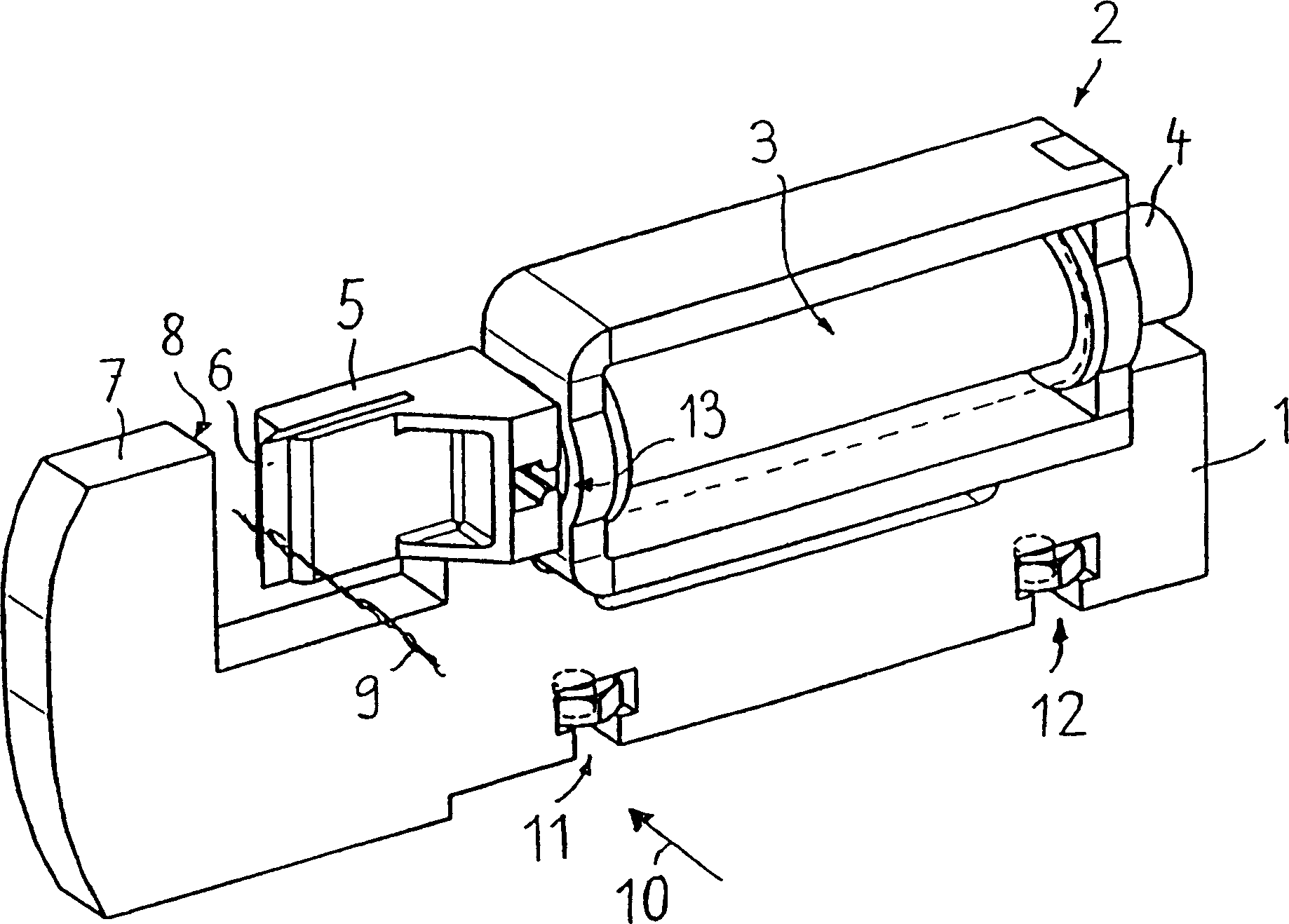

[0013] figure 1 The most important components of the display device, in particular a support 1, a plunger coil 2 with coil 3 and folding armature 4, which form a transmission mechanism for the knife holder 5 and for the blade 6, and a rear seat A frame or anvil 7 is part of the support 1 . The anvil 7 has a hardened surface 8 before which, for example, a thread 9 passes in the direction of the arrow 10 . On the support 1 can be seen the parts of the two screw connections 11 and 12, by means of which the yarn cutting device can be fixed on a textile machine. The blade 6 is preferably fixedly connected to the knife holder 5 and is connected to the plunger armature 4 by a releasable form-fit connection 13 on this side of the knife holder. This is known per se and need not be described in detail here, the coil 3 has figure 1 Windings not shown are connected to a control circuit.

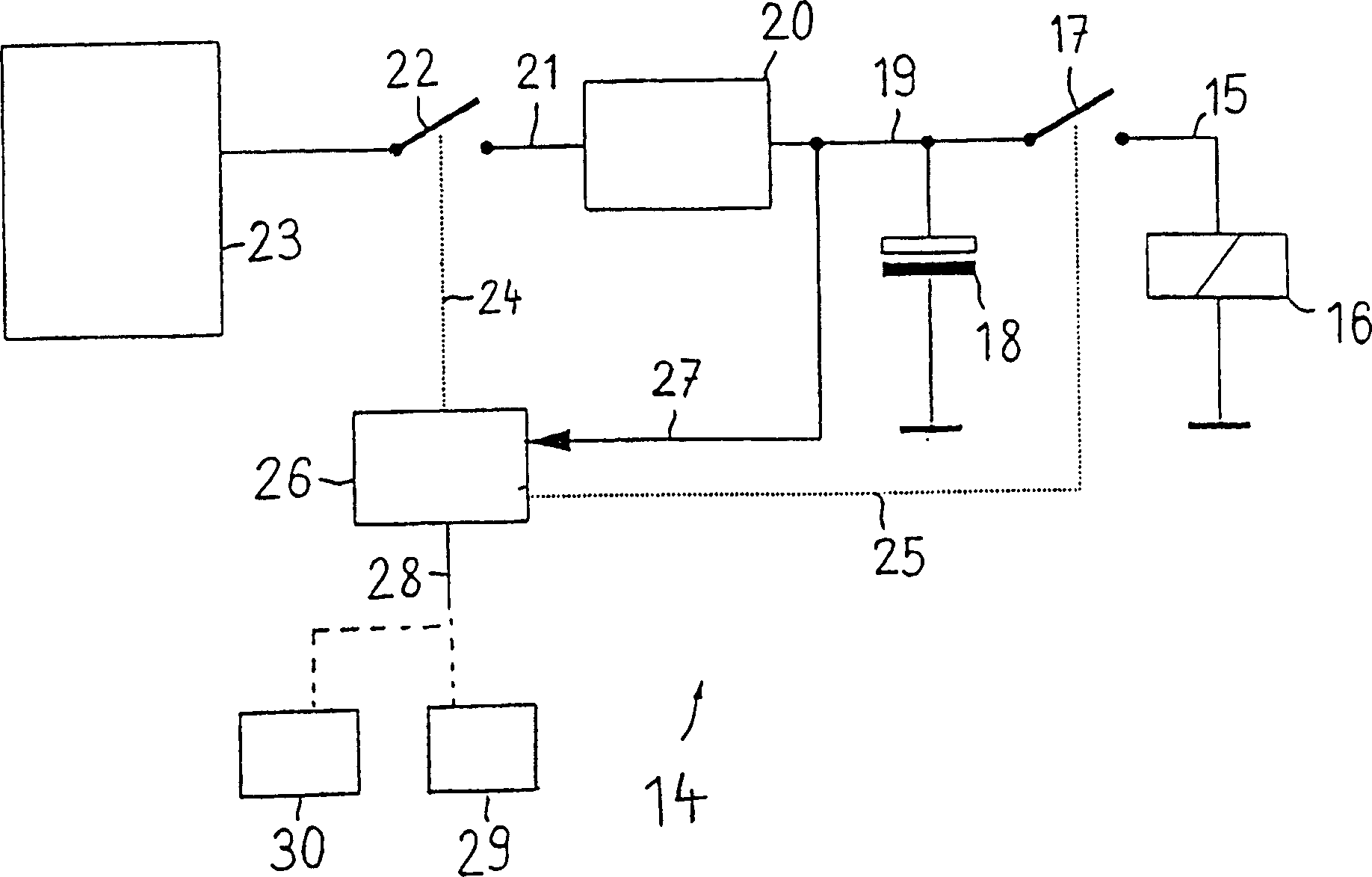

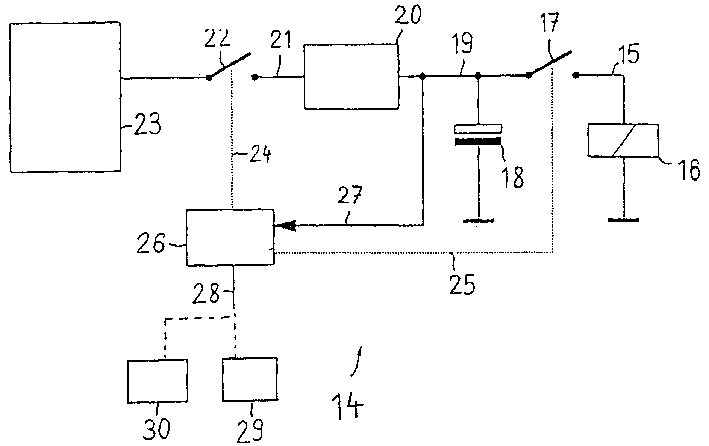

[0014] figure 2 A control circuit 14 is shown as a device for measuring the kinetic energy of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com