On-line micro-oxygen contant measuring method and special sensor

A measurement method and technology of oxygen content, applied in the direction of material resistance, etc., can solve the problems of no thermal effect and low sensor sensitivity, and achieve the effects of excellent sensitivity, improved sensitivity, and reduced thermal noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

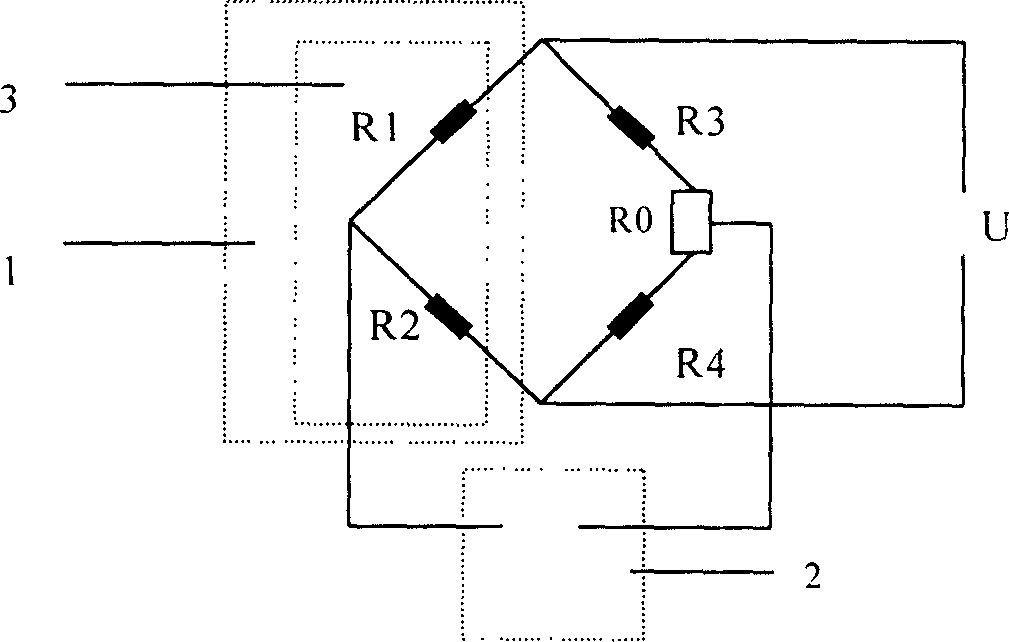

[0035] like figure 1 As shown, the bridge of the special sensor of the present invention is composed of the first to fourth resistors R1, R2, R3, R4, wherein: the first to second resistors R1 and R2 are thermistors, which are used as the reference arm of the bridge and measure arm; the third to fourth resistors R3 and R4 are low-temperature drift resistors, forming the other two arms of the bridge. Thermistors R1 and R2 are placed in the reaction pool 3 that is kept constant by the constant temperature device 1 , and the low-temperature drift resistors R3 and R4 of the bridge circuit are outside the constant temperature device 1 .

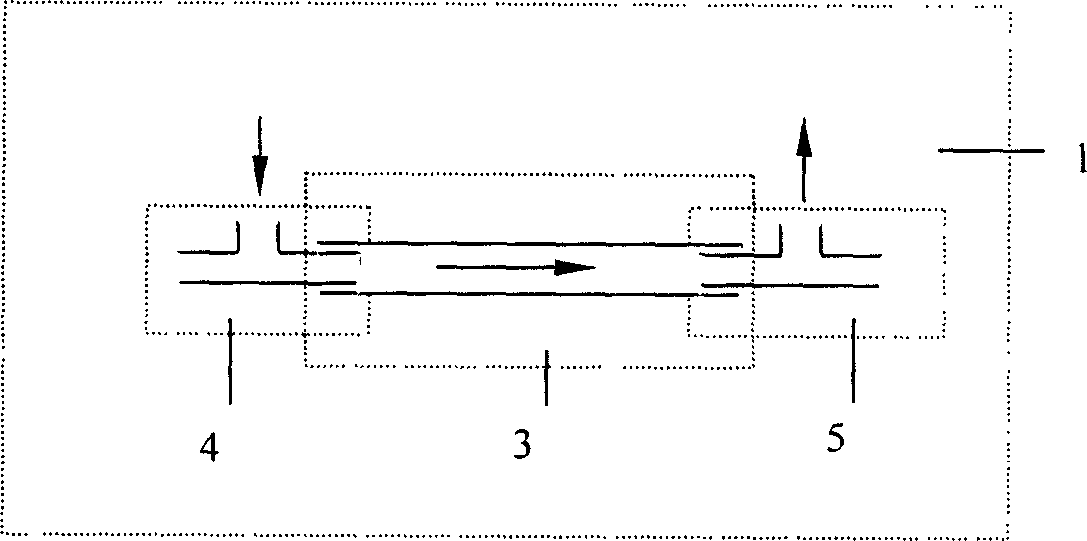

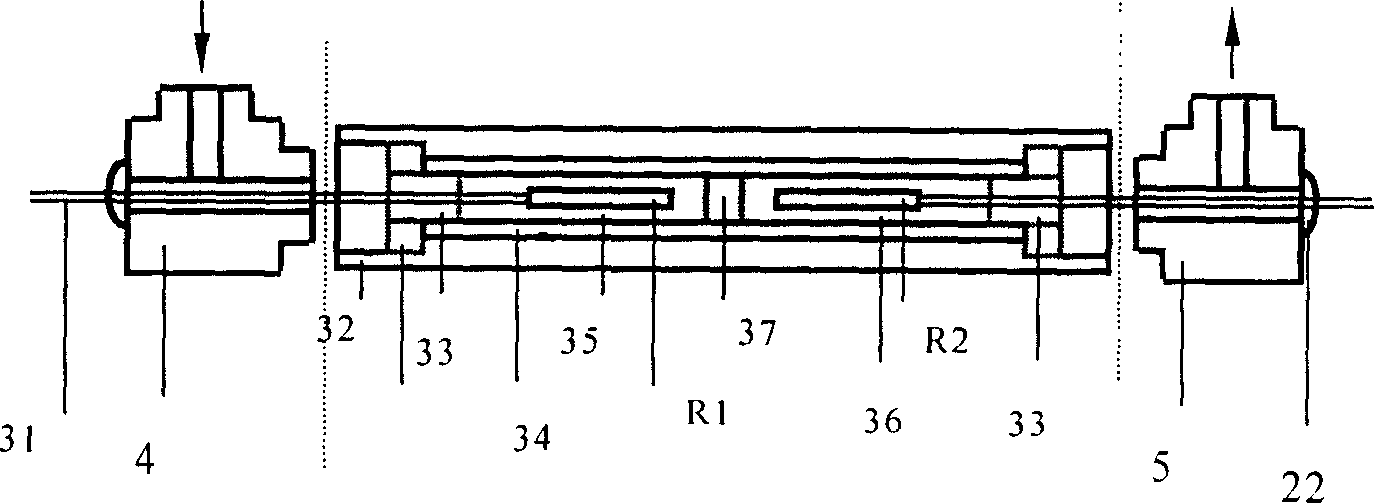

[0036] according to figure 2 , 3 As shown, two thermistors are respectively placed in the reference cell 35 and the measurement cell 36, and the reference cell 35 and the measurement cell 36 are respectively filled with an inert carrier and a catalyst and embed the thermistor; the reference cell 35 It is separated from the measuring pool 36 by ...

Embodiment 2

[0052] 35 fill glass beads in the reference cell, and other conditions are the same as in Example 1.

Embodiment 3

[0054] Glass beads are filled in the reference pool 35; the measuring pool 36 is filled with palladium asbestos catalyst, and other conditions are the same

[0055] Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com