High voltage changeable resistor

A resistor, variable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

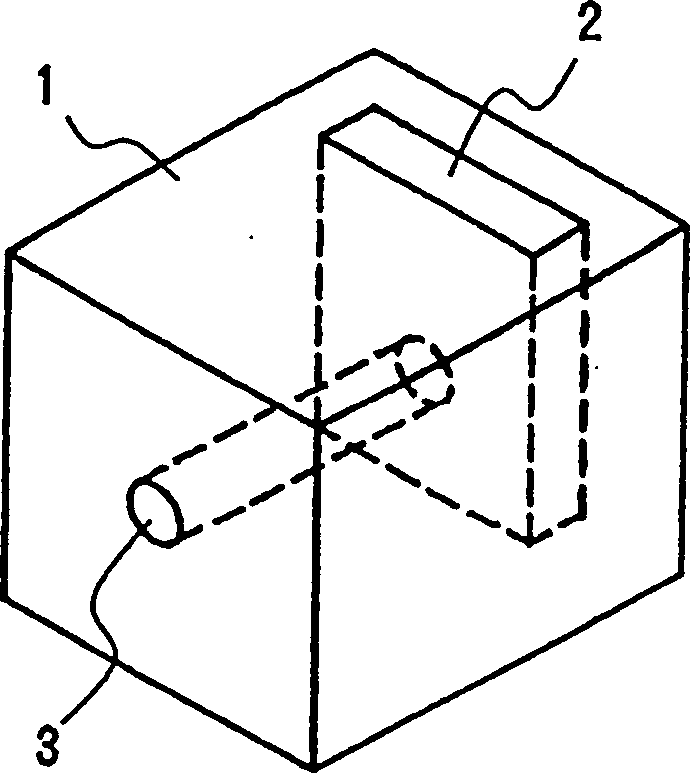

[0038] Refer to below Figure 4 to Figure 8 The high-voltage variable resistor of the preferred embodiment of the present invention is described.

[0039] As an example, the high-voltage variable resistor 10 of this embodiment is used to adjust the focus and measurement of a color TV or a color display. The high-voltage variable resistor 10 includes an insulating housing 11 made of highly flame-retardant materials, such as polybutylene terephthalate, polyphenylene ether, and polycarbonate; a circuit board 23 placed in the housing 11; Variable resistors 24, 25, 26; focus output sections 27 and 28; screen output section 29. in spite of Figure 4 Only the control buttons of the variable resistors 24, 25, and 26 are shown, and the slider attached to each control button slides on a resistor (not shown) formed on the surface of the circuit board 23, thereby setting the desired resistance value . The number of variable resistors can be one, two or more than four. Three output sections are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com