Method for dynamically defining etch-recording speed of optical disk etch-recording machine

A recorder and speed technology, applied in optical recording/reproducing/erasing methods, recording/reproducing by optical methods, optical recording systems, etc., can solve the waste of discs, the failure of recording operations, and the lack of disc recording data. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

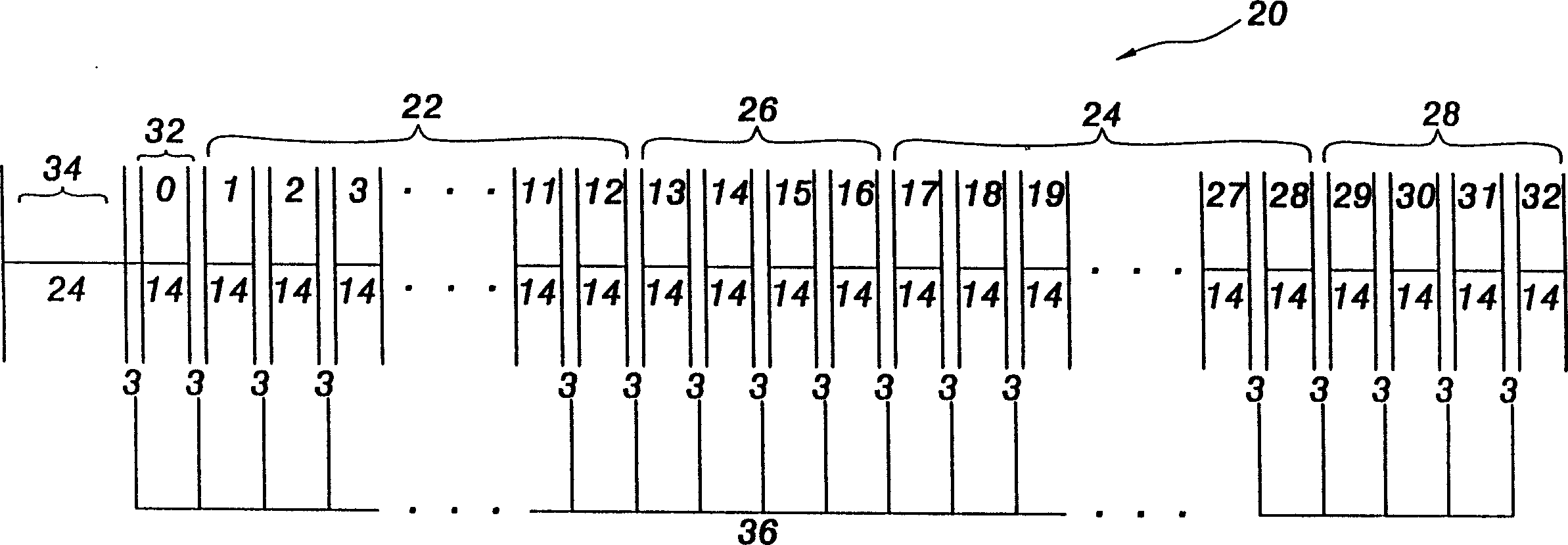

[0019] see figure 1 , figure 1 It is a schematic diagram of a data signal 20 written to an optical disc.

[0020] The data signal 20 takes an optical disc sound signal as an example, including two data bytes 22 and 24, a Q parity byte (Q parity) 26, a P parity byte (P parity) 28, sub A subcode 32 and a sync word 34 . Data bytes 22 and 24 respectively contain 12 bytes of digital data, Q parity byte 26 and P parity byte 28 contain 4 bytes of digital data respectively, and subcode byte 32 contains There is 1 byte of digital bit data. Add data bytes 22, 24, Q parity byte 26, P parity byte 28 and subcode byte 32 to obtain a data length equal to 33 bytes of digital bit data (0 in the icon) -32 sections). The aforementioned 33-byte digital bit data is subjected to an Eight-to-Fourteen Modulation (Eight-to-Fourteen Modulation, EFM) method to obtain a 462-bit Eight-to-Fourteen Modulation code (EFM code). Synchronization block 34 does not need to undergo eight-to-fourteen modulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com