Vector controller without speed sensor

A vector control and estimated value technology, which is applied in the field of speed sensorless vector control devices, can solve the problems that the magnetic flux speed cannot be calculated, the secondary magnetic flux cannot be calculated, and the speed is difficult to estimate stably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

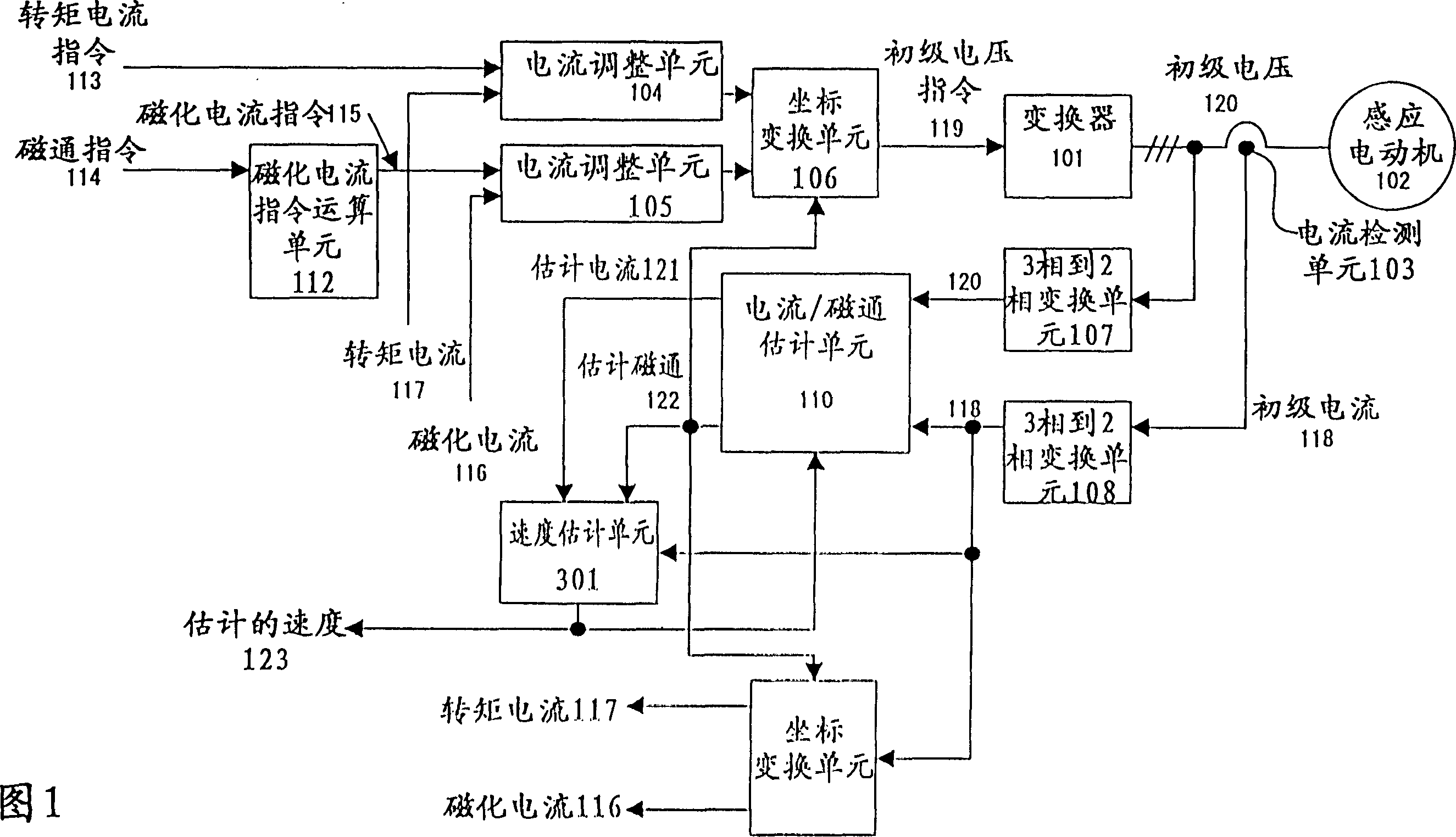

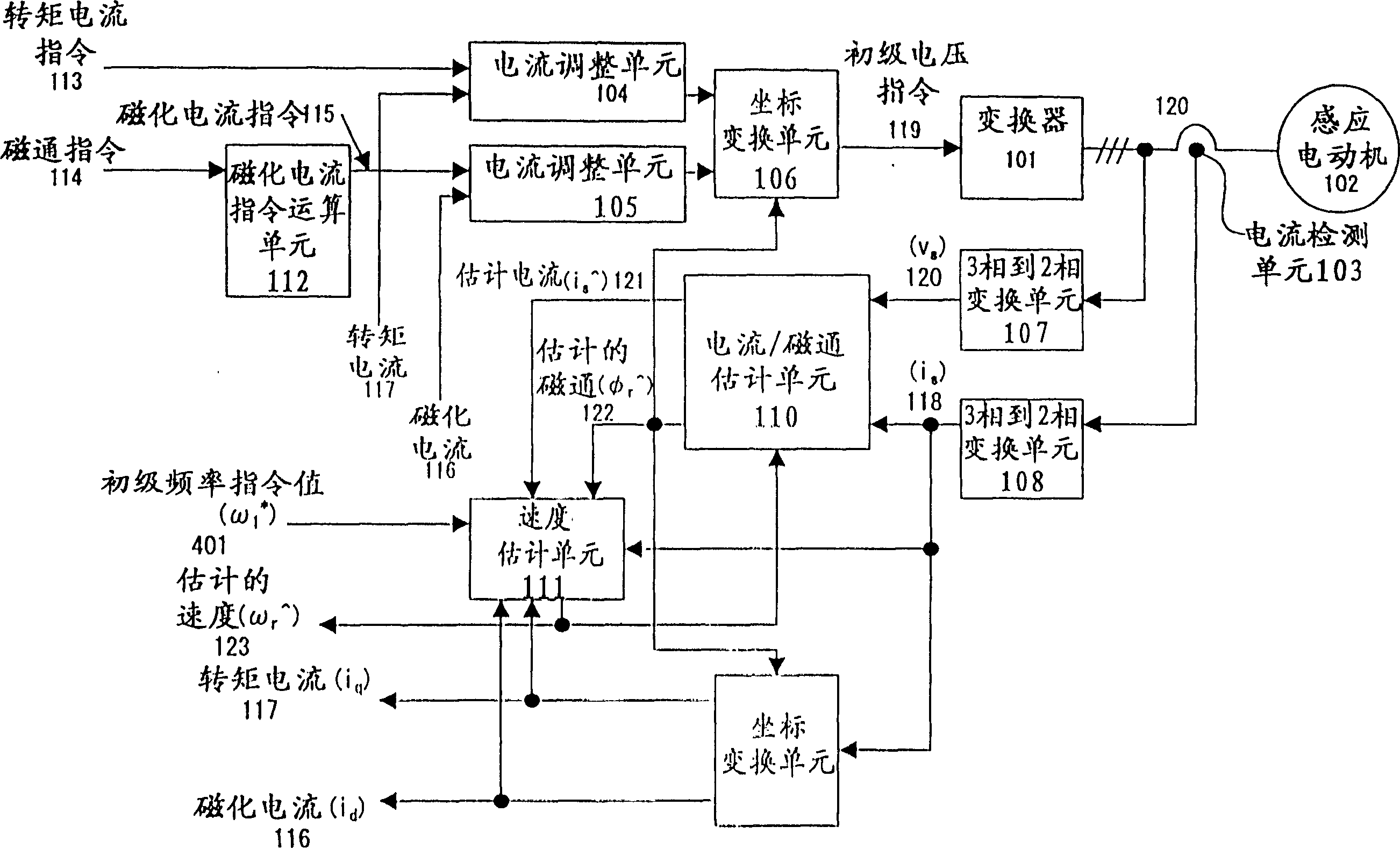

[0058] Embodiments of the present invention are described below with reference to the drawings.

[0059] attached image 3 Shown is a control block diagram of an embodiment of the invention. The difference from the block diagram shown in FIG. 1 lies in the structure of the speed estimation unit 111 . The speed estimation unit 111 further receives the primary frequency command value (ω 1 * ) 401, magnetizing current (i d ) 116 and torque current (i q )117. The other units are the same as those shown in FIG. 1 . Therefore, the same reference numerals as those shown in FIG. 1 are assigned, and their explanations are omitted here.

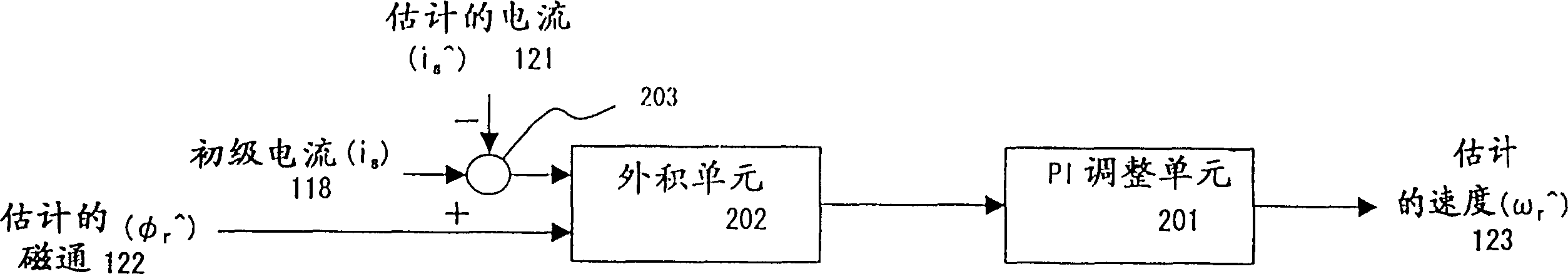

[0060] FIG. 4 shows the internal structure of the speed estimation unit 111 .

[0061] Refer to the attached figure 2 Describe the structure. with attached figure 2 In comparison, the structure shown in FIG. 4 further includes addition / subtraction units 205 and 305, multiplication units 306 and 309, gain element 304, absolute value operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com