Kaolinite intercalation method

A kaolinite and solution technology, applied in the direction of aluminum silicate, silicate, etc., can solve the problems that the intercalation purpose cannot be achieved, the intercalation cannot be realized, the process is complicated, etc., and the interlayer distance is large, the intercalation time is short, The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

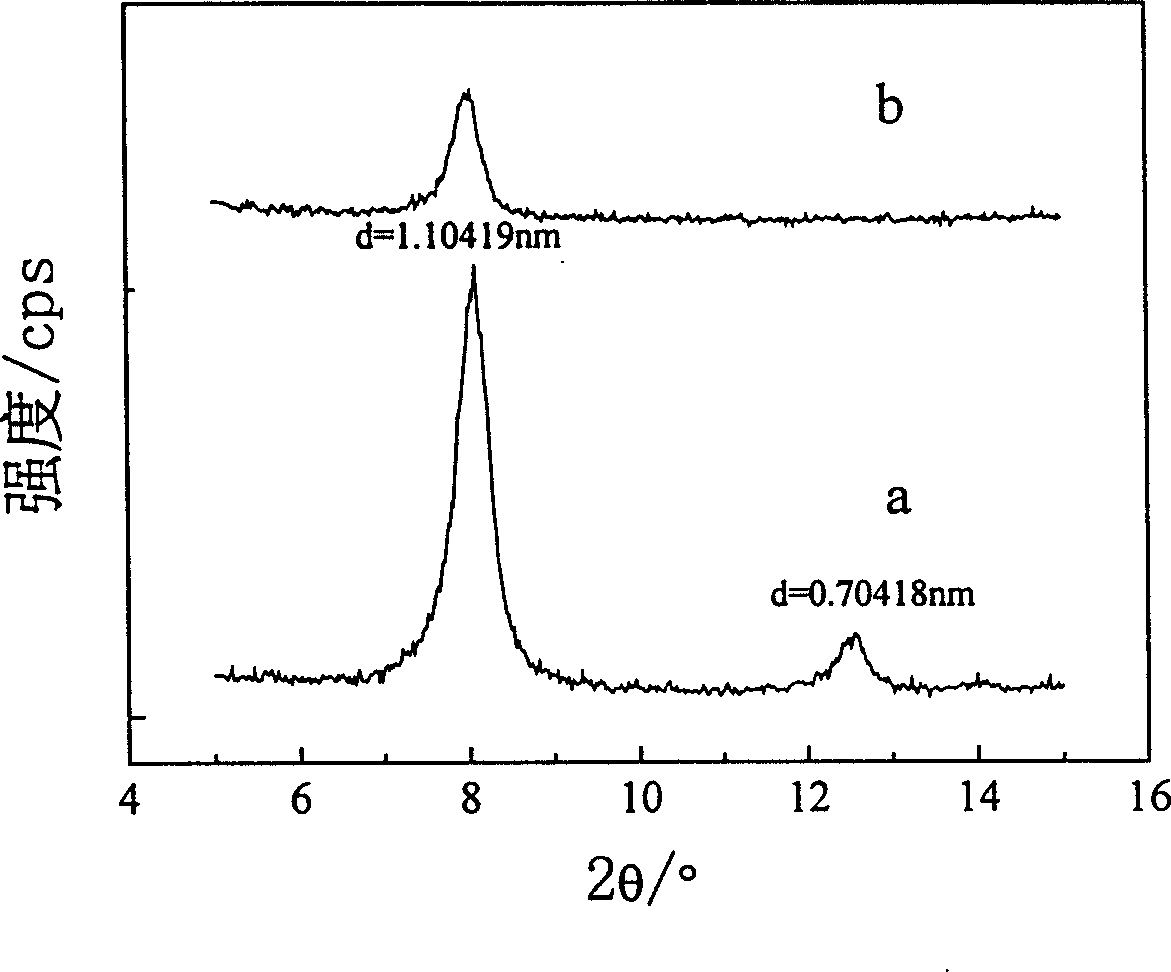

[0007] Example 1: Dimethyl sulfoxide was dissolved in distilled water to prepare a 10.7mol / L solution; kaolinite passed through a 100-mesh sieve was added to the above solution at a mass ratio of 1:20, and dispersed evenly. The generating head of the chemical generator was put into the above solution, and reacted at an ultrasonic frequency of 25KHz for 1 hour and at an ultrasonic frequency of 35KHz for 2 hours under stirring. Then filter the solution and dry naturally to obtain the kaolinite intercalation compound intercalated by dimethyl sulfoxide. The obtained intercalation compound was analyzed by X-diffraction analyzer.

[0008] Referring to the accompanying drawings, the X-diffraction analysis figure of the intercalation compound of kaolinite intercalated with dimethyl sulfoxide, in the figure a represents the X-diffraction analysis of the intercalation compound obtained after reacting for 1 hour at an ultrasonic frequency of 25KHz In the figure, b in the figure represen...

Embodiment 2

[0012] Example 2: Diethanolamine was dissolved in distilled water to prepare a 5mol / L solution; kaolinite was pulverized and passed through a 100-mesh sieve, and added to the above solution at a mass ratio of 1:30, and dispersed evenly to obtain a mixed solution; Put the generation head of the sonochemical generator into the mixed solution, and perform sonochemical intercalation at an ultrasonic frequency of 15KHz under stirring, and the ultrasonic action time is 4 hours; filter the solution after sonochemical intercalation, and pass through The kaolinite intercalation compound intercalated with diethanolamine can be obtained by natural drying.

Embodiment 3

[0013] Embodiment 3: dissolving triethanolamine in distilled water is prepared into a solution of 16.7mol / L; kaolinite is pulverized and passed through a 100 mesh sieve, and added to the above solution with a mass ratio of 1:20, and dispersed evenly to obtain a mixed solution; The generation head of the frequency acoustic chemical generator is put into the mixed liquid, and it is sonochemically intercalated at an ultrasonic frequency of 25KHz under the stirring state, and the ultrasonic action time is 0.8 hours; the solution after the sonochemical intercalation is filtered, The kaolinite intercalation compound intercalated with triethanolamine can be obtained after natural drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com