Shell structure for plane display

A flat-panel display and shell structure technology, which is applied in the fields of instruments, electrical equipment shells/cabinets/drawers, electrical digital data processing, etc., and can solve problems such as difficult design, difficult change, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

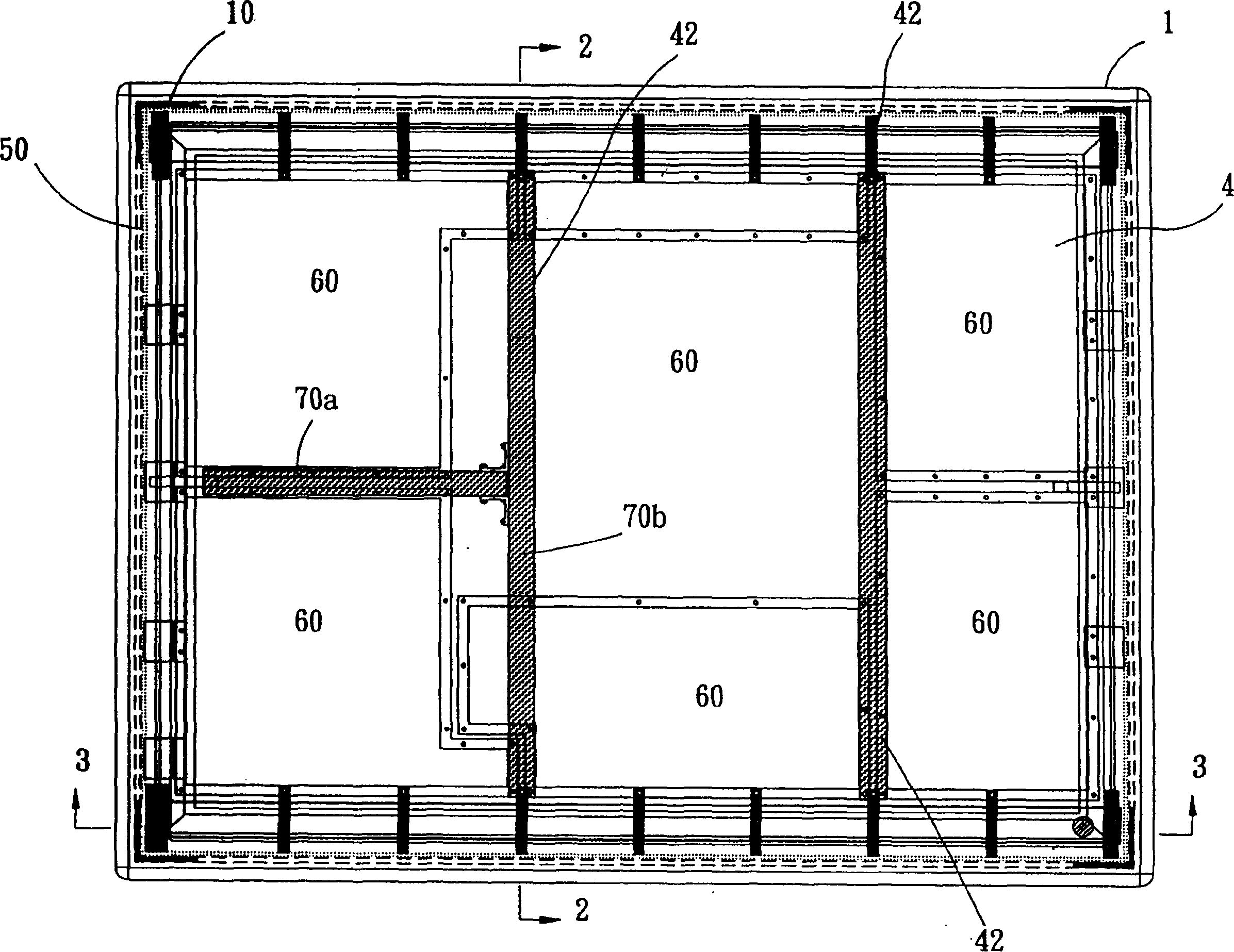

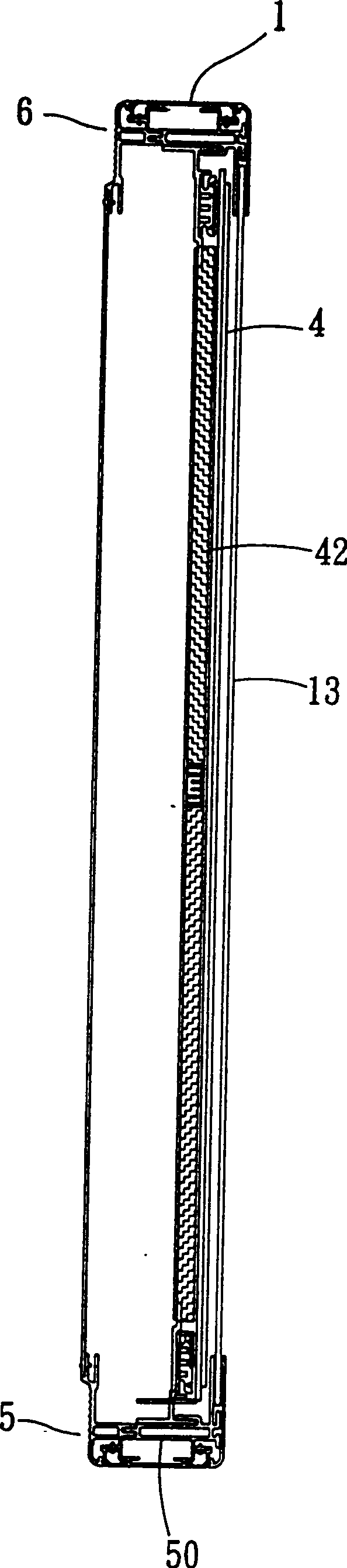

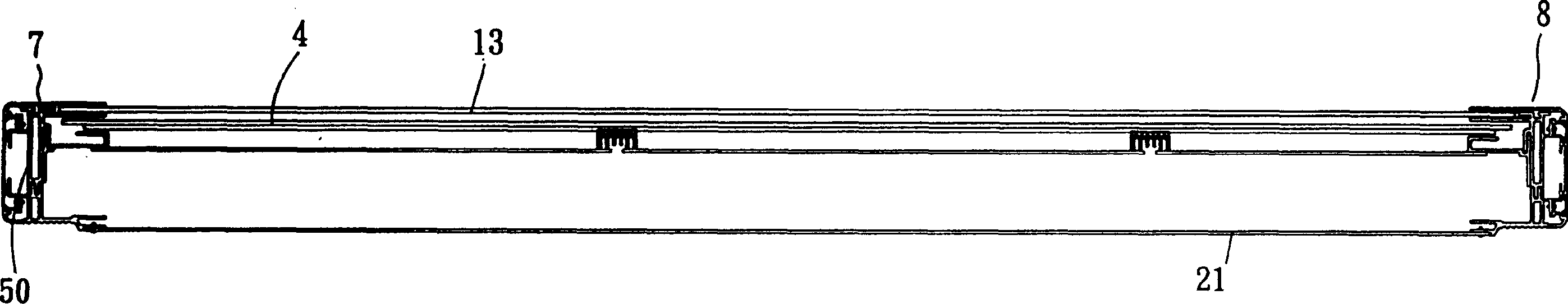

[0032] The present invention relates to a shell structure of a flat-panel display, in particular, to a shell structure of a flat-panel display made of extruded aluminum parts, such as extruded aluminum parts.

[0033] Please refer to Figure 1 to Figure 6 ,in figure 1 It is a schematic diagram of the appearance of the first embodiment of the housing structure of the flat-panel display of the present invention, which is used to show the first embodiment of the housing structure of the flat-panel display of the present invention. In this first embodiment, the flat-panel display is a plasma display, and the housing structure 1 and the flat-panel display panel 4 are combined to form a flat-panel display. The housing structure 1 of the flat-panel display of the present invention can accommodate a flat-panel display panel 4. The housing includes a modular aluminum extruded frame 50, and the inner side of the modular aluminum extruded frame 50 has an opening and a front edge. and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com