Manufacture of fluorescent lamp glass tubes

A glass tube and fluorescent lamp technology, applied in glass manufacturing equipment, discharge tube/lamp manufacturing, glass molding, etc., can solve the problems of high defective rate of lamps and weakened end walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

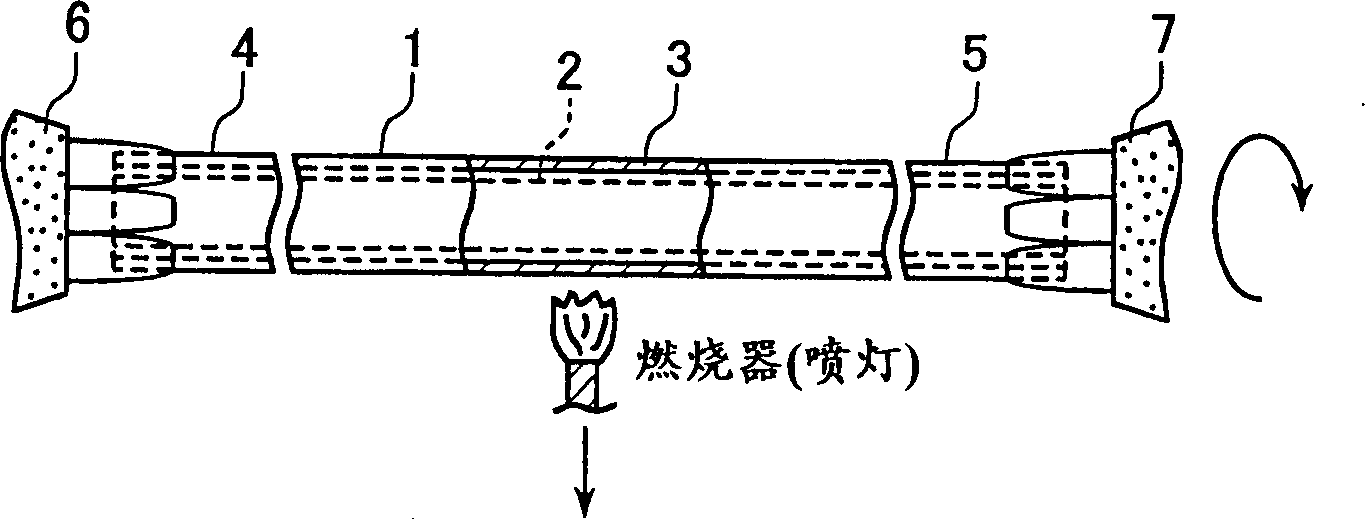

[0035] The following reference Figure 1A-1F A method of manufacturing a fluorescent lamp according to an embodiment of the present invention is explained.

[0036](1) A straight glass tube rotates around the tube axis, wherein the straight glass tube has, for example, a wall thickness of 0.85mm and an outer diameter of 16.5mm, and a fluorescent substance 2 is coated on the inner surface. Predetermined cutting portion 3 is heated, for example by torch heating ( Figure 1A ). Here, the ends 4 and 5 of the glass tube 1 are fixed by a pair of coaxial chucks 6 and 7 respectively, and so the glass (tube) is processed with great precision throughout the subsequent steps.

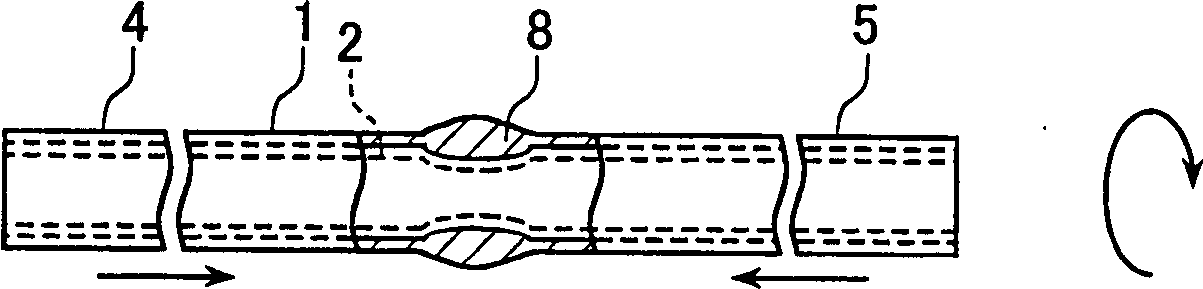

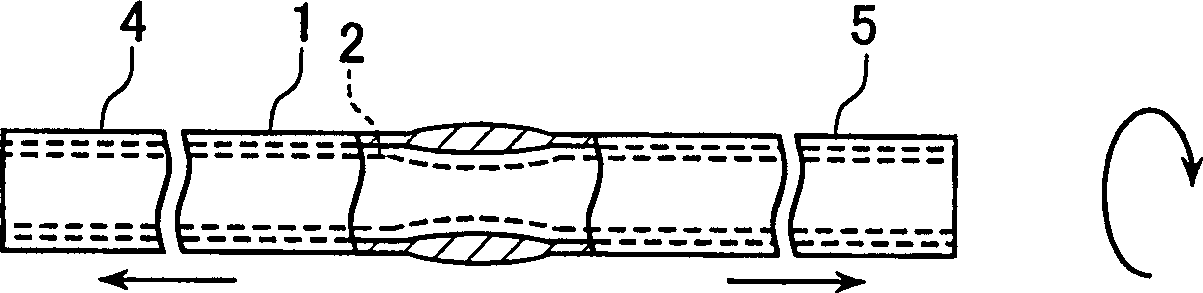

[0037] (2) When the predetermined cutting part 3 of the glass tube is heated and softened, while the glass tube is continuously heated by the torch, the ends of the glass tube 1 are respectively moved towards the predetermined cutting part 3 at a speed of 1.66 mm / 8. Move 2.5mm (by applying pressure in an inward...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com