Screw compressor

A screw compressor, compressor technology, applied in mechanical equipment, machine/engine, liquid fuel engine, etc., can solve problems such as increasing the size of the cooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

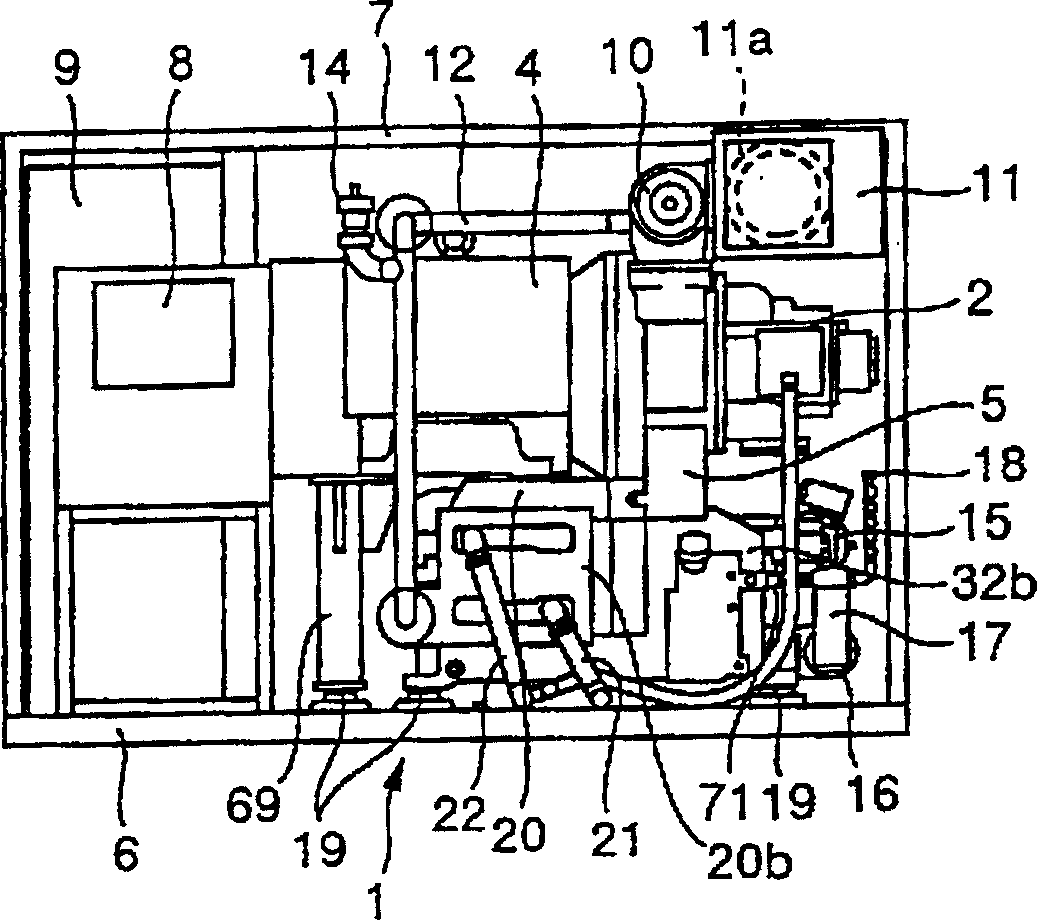

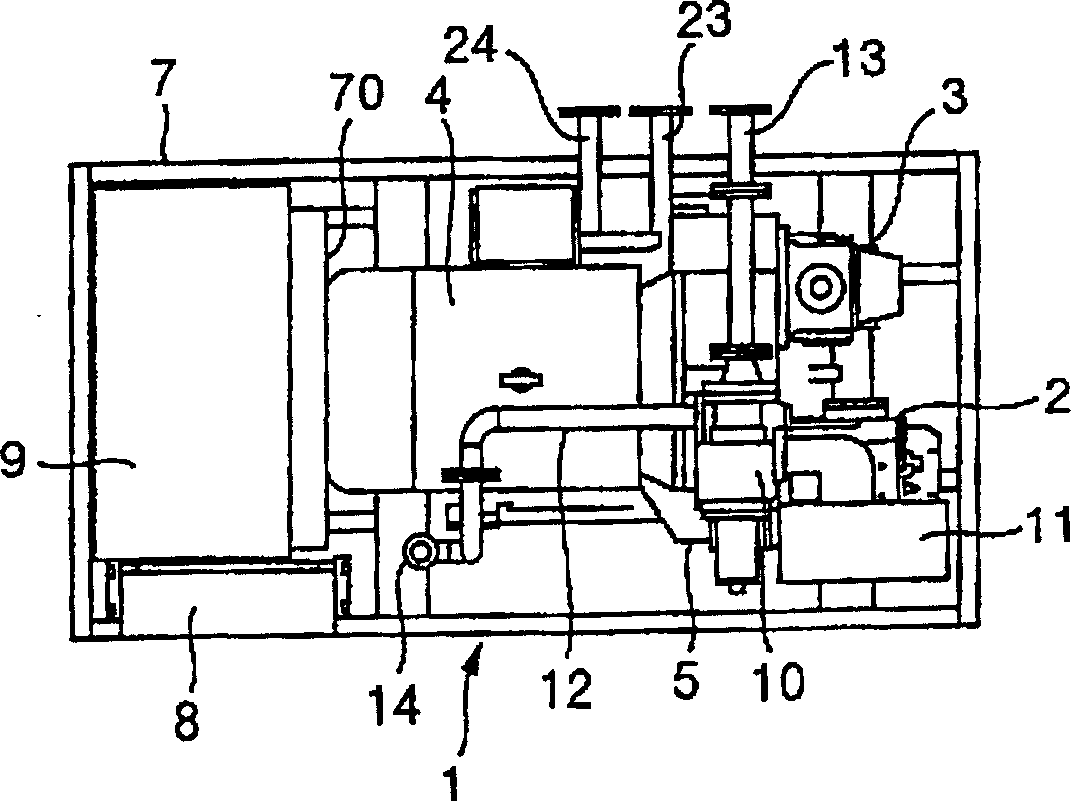

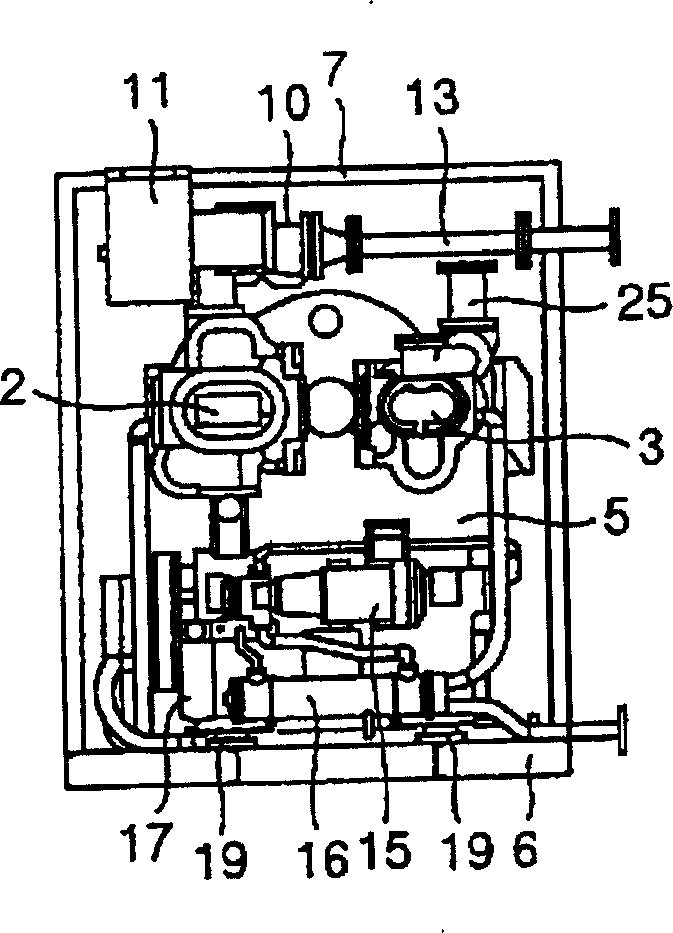

[0025] Next, an embodiment of the cartridge unit type screw compressor of the present invention will be described with reference to the drawings. Figure 1 to Figure 3 shows the appearance of the screw compressor of the present invention, Figure 4 and Figure 5 yes figure 1 Illustrative diagram of the working air flow in the screw compressor shown. Figure 15 After removing the soundproof cover figure 1 Perspective view of the shown cartridge unit screw compressor.

[0026] The screw compressor 1 of this embodiment is a two-stage compressor, including a low-pressure stage (first stage) compressor 2 and a high-pressure stage (second stage) compressor 3, and this screw compressor 1 is a so-called dry screw compressor, Of course, the meshing parts of its screw rotor do not require lubrication. The gas handled by this screw compressor is air. The discharge pressure of the screw compressor 1 (the discharge pressure of the second-stage compressor) is about 0.7-1.0 MPa (gauge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com