Vacuum laser dam deformation measuring method

A measurement method and laser technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high cost and large diameter of vacuum pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] This embodiment will compare and illustrate the vacuum laser dam deformation measurement system before and after adopting this method.

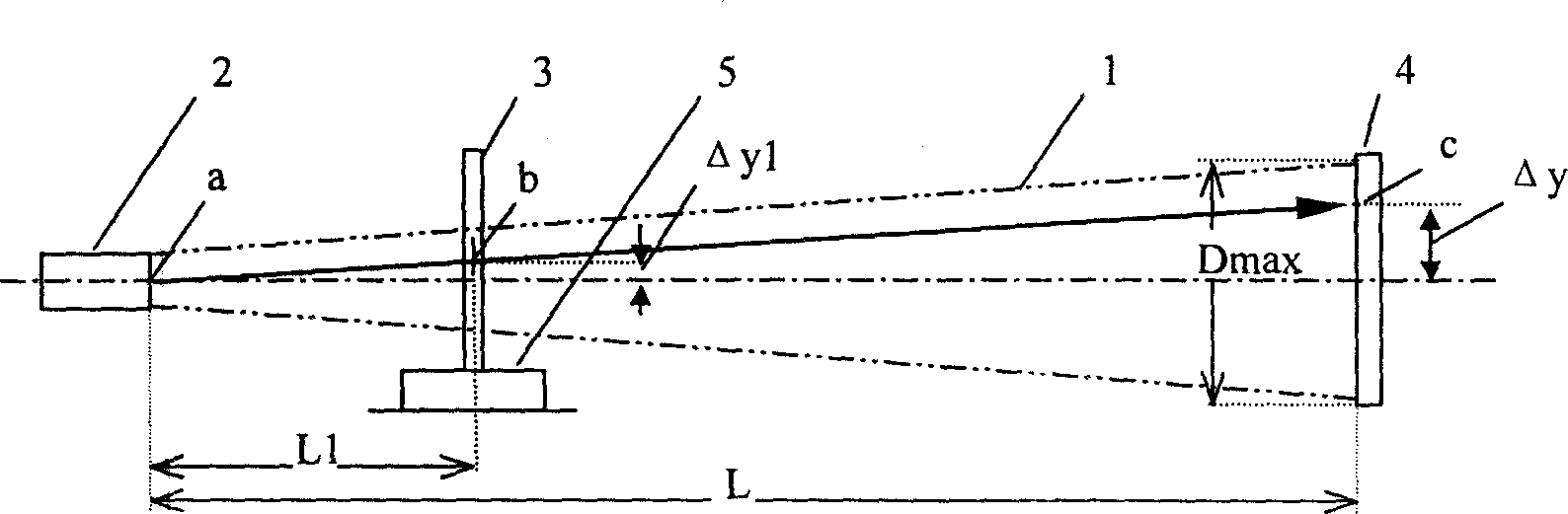

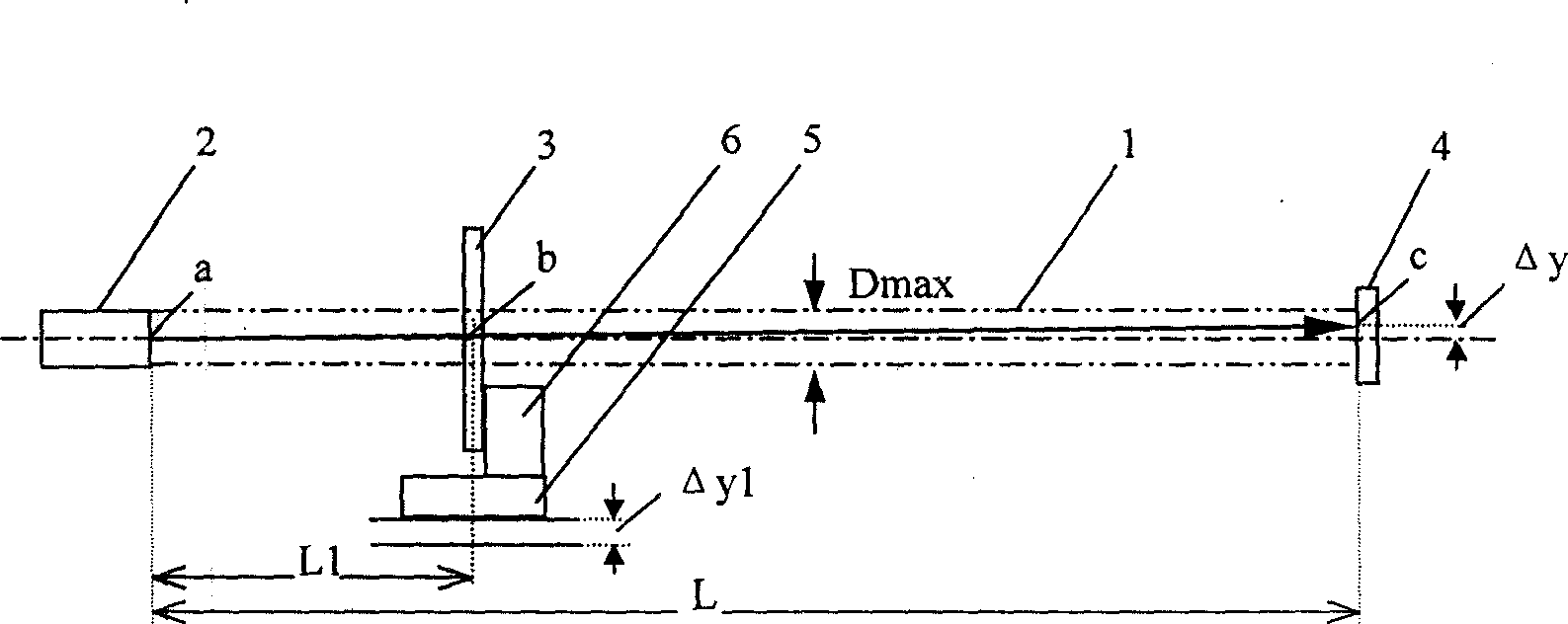

[0019] Before adopting this method in a vacuum laser dam deformation measurement system, the system structure is as follows: figure 1 shown. The system consists of a vacuum pipeline 1, a laser light source 2, a zone plate 3, a laser receiver 4 and a measuring point base 5. The laser light source 2 is 1000 meters away from the laser receiver 4, the distance between the measuring point base 5 and the laser light source 2 is 100 meters, the wave zone plate 3 and the measuring point base 5 are fixed together, and the diameter of the vacuum pipeline near the laser emitting end is 159 mm. When the deformation of the measuring point vertical to the laser axis is 20mm, according to the triangular relationsh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com