Vacuum degassing device of glass melt

A technology of vacuum degassing device and glass melt, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of glass melt leakage, erosion of thermal insulation materials, shortening the service life of vacuum degassing device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

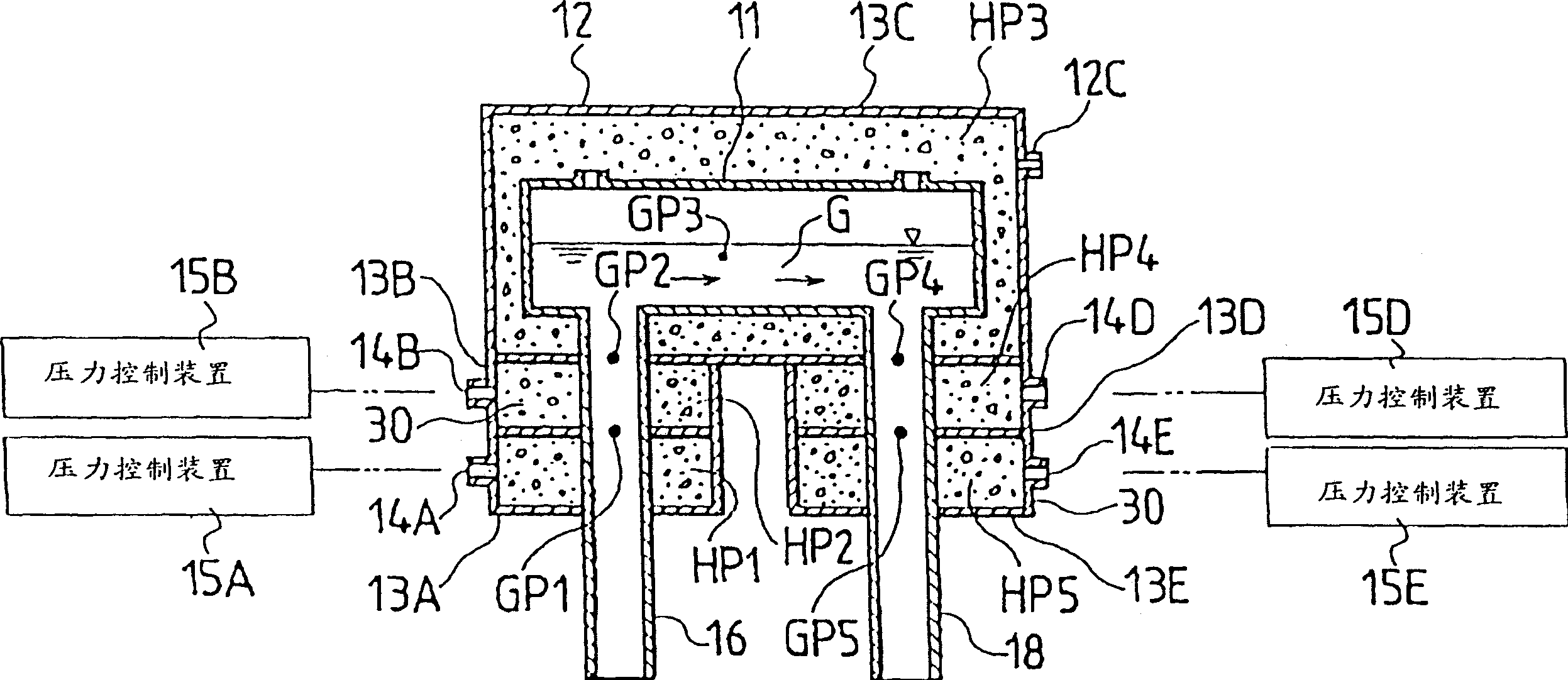

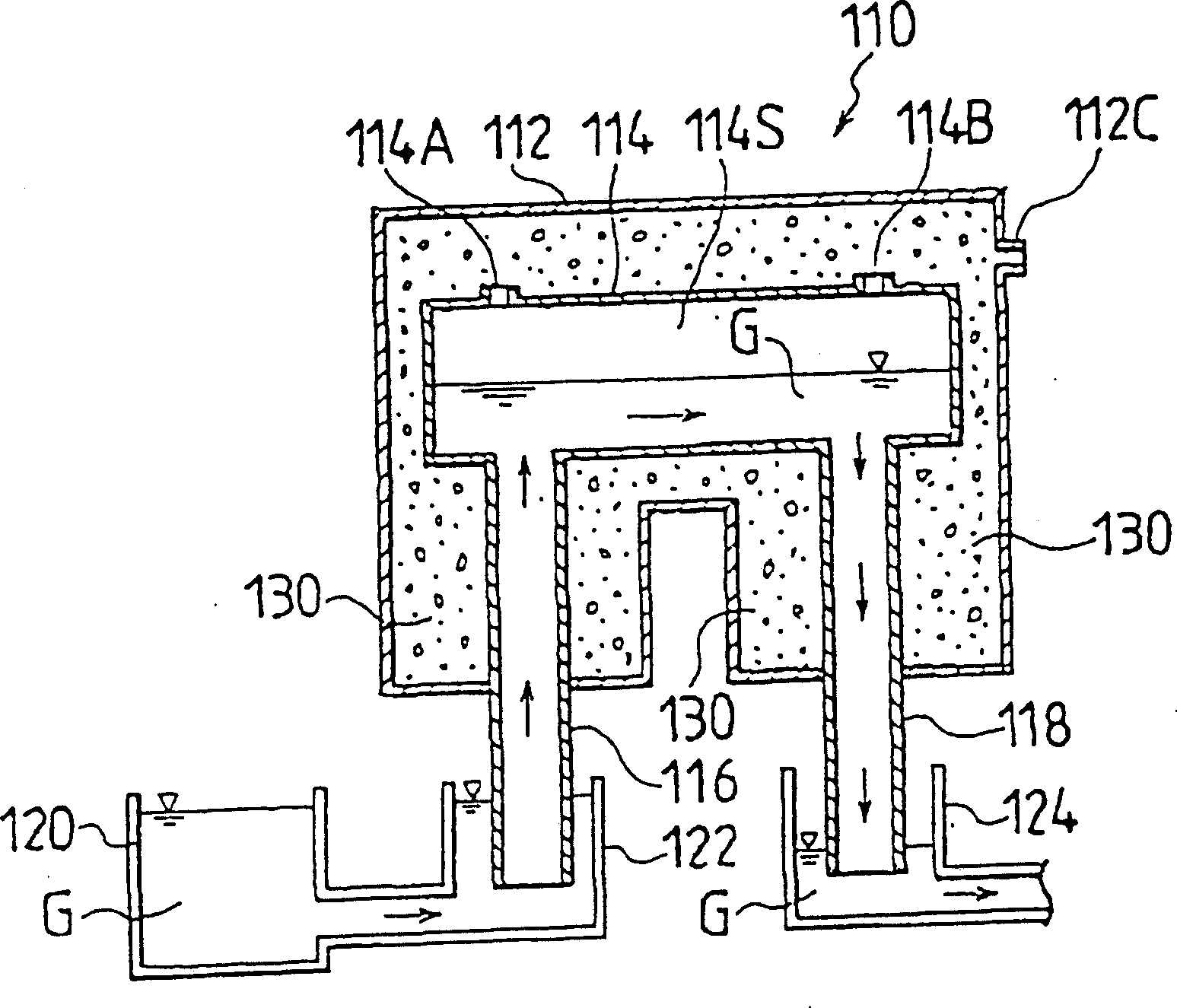

[0026] Now, the vacuum degassing apparatus for glass melt of the present invention will be described in detail with reference to preferred embodiments shown in the accompanying drawings.

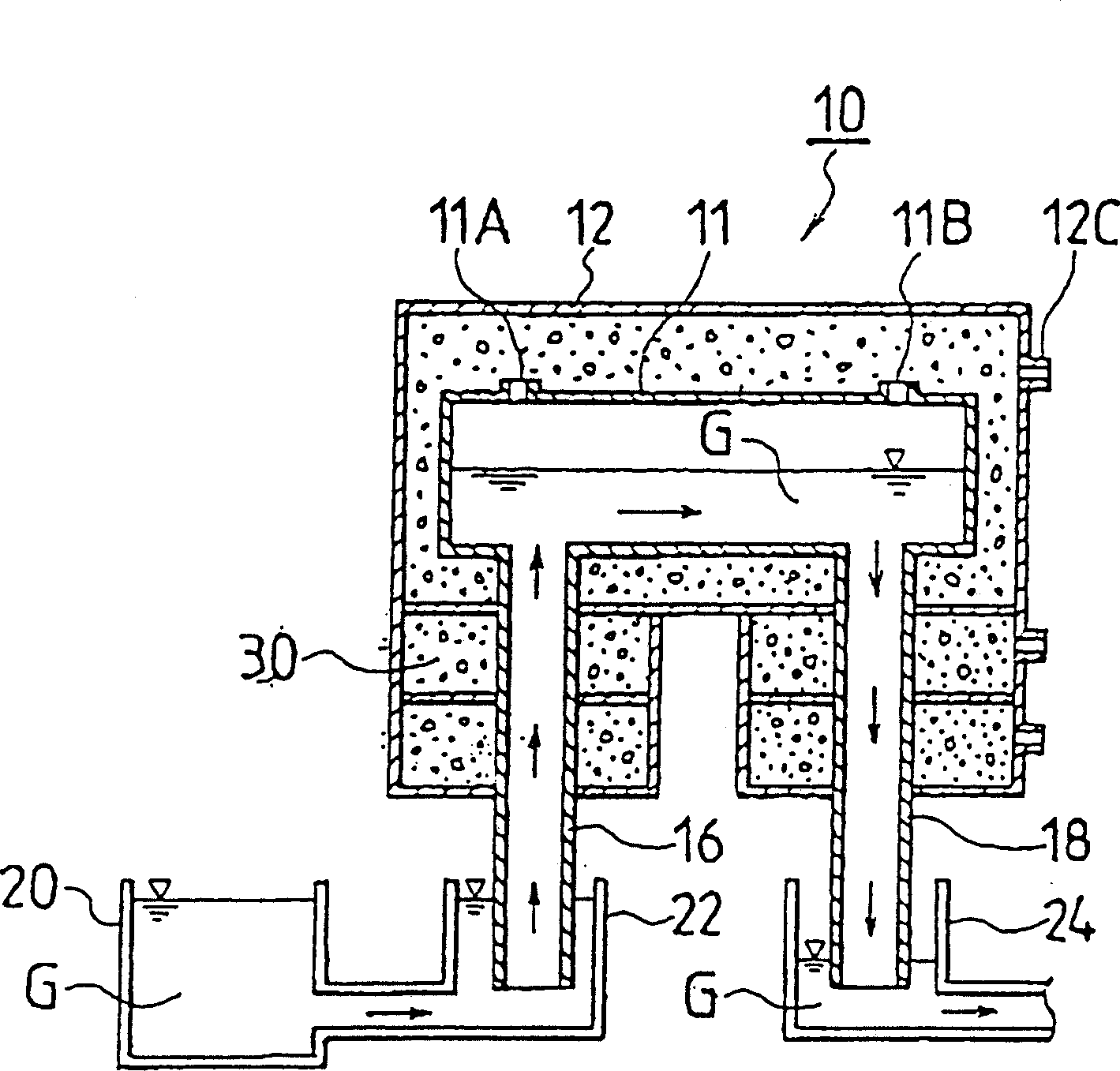

[0027] like figure 1 The vacuum degassing device 10 for the glass melt in the shown embodiment comprises a substantially right-angled vacuum housing 12 made of stainless steel, a vacuum degassing tank horizontally placed in the vacuum housing 12 and having a rectangular cross-sectional shape 11. An ascending pipe 16 and a descending pipe 18 vertically mounted on the vacuum housing 12 , the respective upper ends of the ascending pipe and the descending pipe are connected to the right end and the left end of the vacuum degassing tank 11 .

[0028] The vacuum degassing device 10 used in this method is used in the process of vacuum degassing the glass melt G in the melting tank 20, and the degassed glass melt is continuously supplied to the subsequent treatment tank (not shown) , such as a for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com