Water-proof heat insulation metal roof

A metal and roof technology, applied in the direction of roof covering layer, roof using tile/slate tile, roof using flat/curved panel, etc., can solve the problems of short service life, reduced porosity, complicated construction process, etc. achieve long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

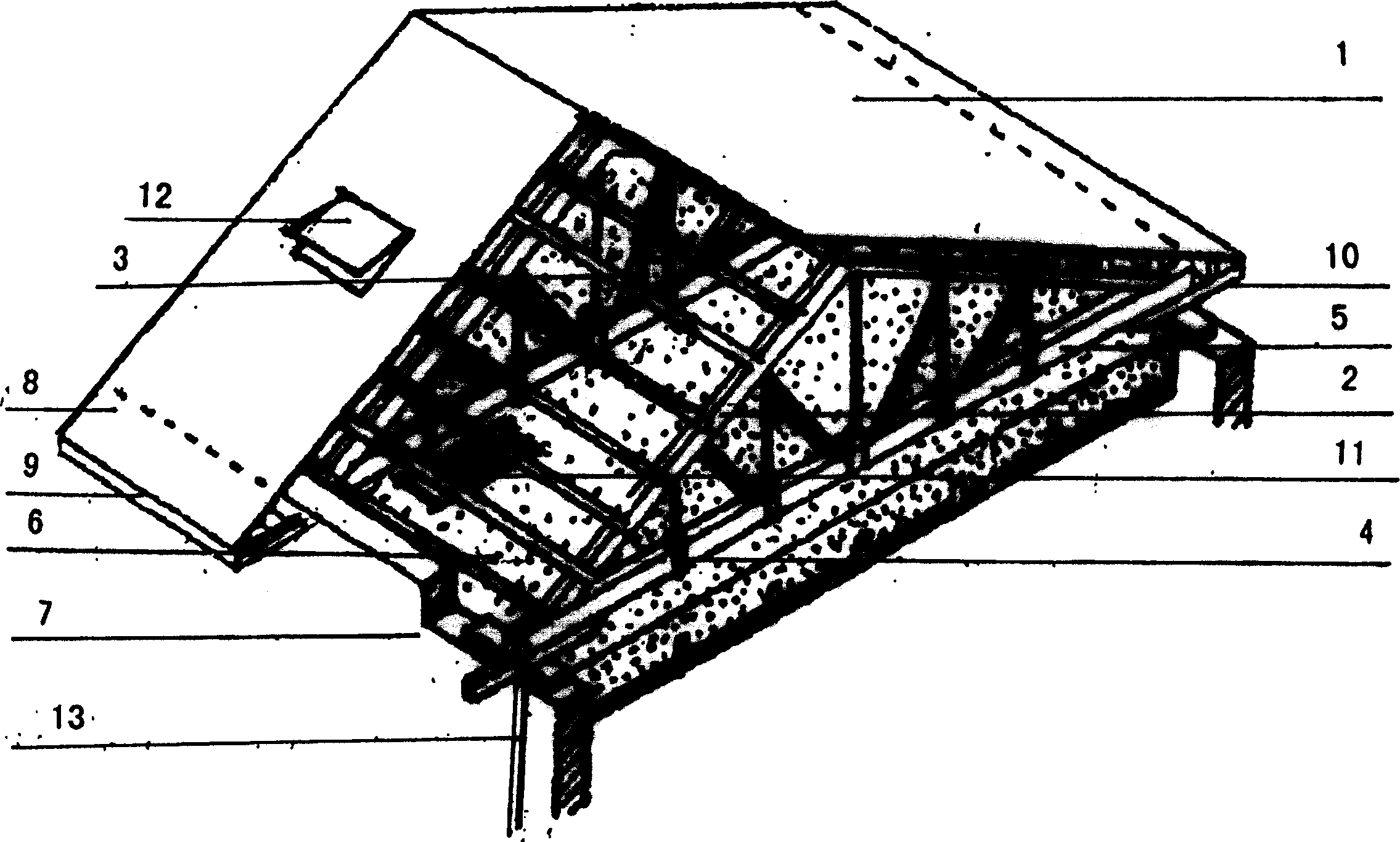

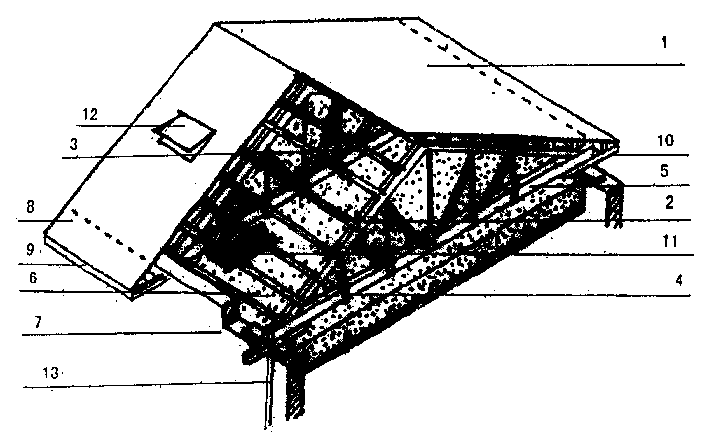

[0012] See figure 1 , The L-shaped metal materials are combined and fixed into two roof trusses 2; the roof trusses 2 are fixed on the roof frame 3 with multiple C-shaped or L-shaped metal materials in a "well" shape; the height of the entrance 11 of the original stairwell is 2.8 meters. For the convenience of construction, remove it to 1.5 meters or leave only the entrance. If only the entrance is left, a fence should be welded with steel on the three sides of the entrance and fixed on the roof 6 with the remaining side as a passage; Choose multiple profiles with a length of 1200mm and fold them into eaves 8, suspended eaves 9 and eaves ceiling 10. The dimensions are 500mm for eaves 8, 200mm for eaves 9 and 500mm for eaves ceiling 10, and then one end of multiple eaves 8 They are respectively fixedly connected with the edge metal materials of the outer wall of the roof frame 2 and the roof frame 3, and the other ends of the multiple eaves suspended ceilings 10 are fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com