Methods and systems for installing cable and conduit in pipelines

A technology of pipelines and conduits, applied in the direction of cable installation, pipeline laying and repair, pipeline support, etc. in underground pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

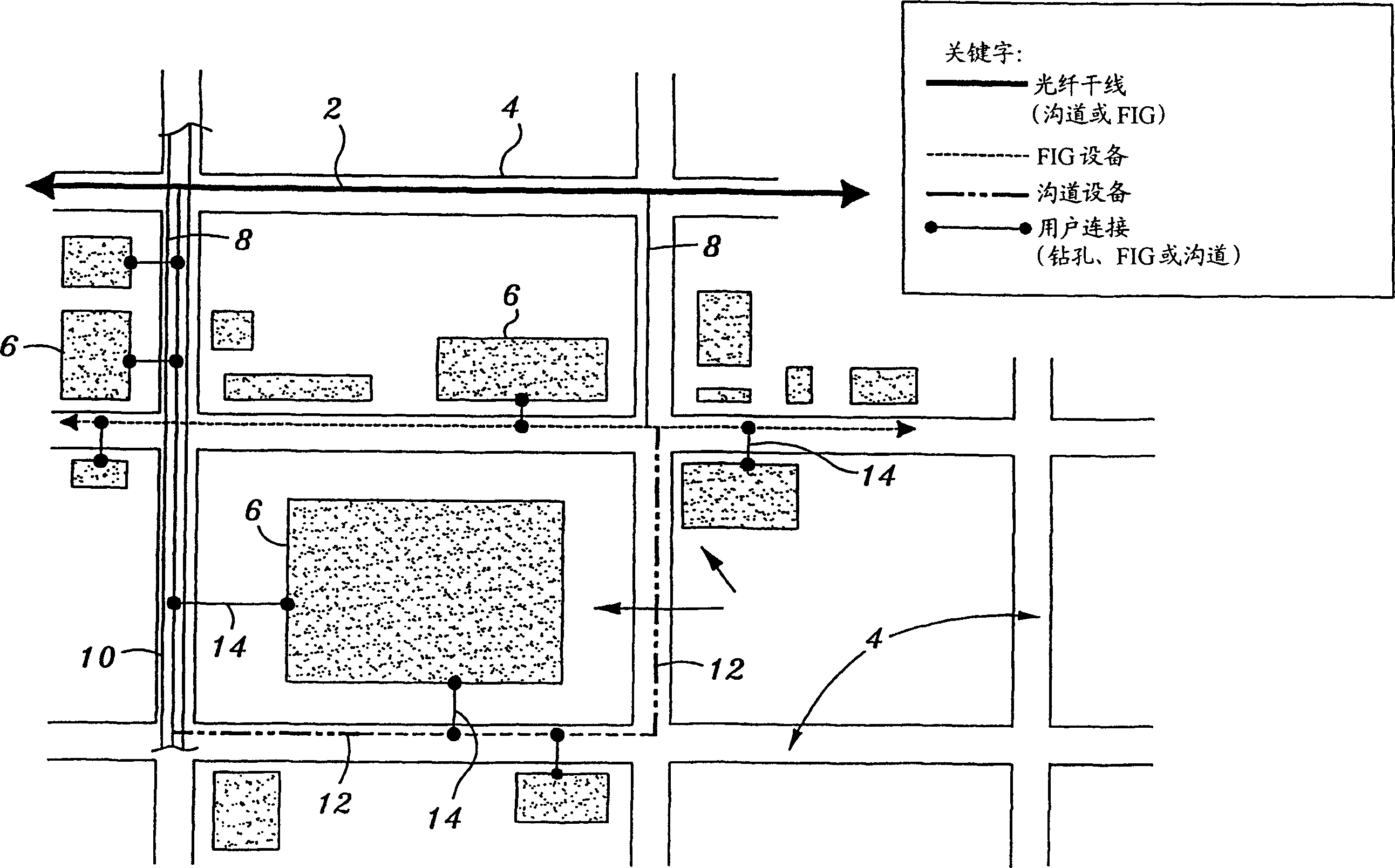

[0075] figure 1 A map or plan showing a portion of an urban area such as a city, town, college campus, etc. The main fiber optic trunk line 2 underlies one or more streets 4 . Various buildings 6 are scattered around the main fiber optic trunk line 2 . These buildings 6 may be individual properties, or the buildings 6 may be a campus that includes a variety of properties. Shown is a fiber optic conduit 8 carrying one or more bundles of fiber optic cables, branching off from the main fiber optic trunk 2 below the street 4 . The fiber optic conduit 8 is provided in a pressurized gas pipeline 10 located underground. The fiber optic conduit 8 is installed according to the method and apparatus described below.

[0076] still refer to figure 1 , in some streets 4 there is no existing pressurized gas pipeline 10, or the pipeline size or available capacity is not suitable for installing conduits or cables. In this case, the fiber optic conduit 8 is preferably installed in a conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com