Film optical addressing electric potential sensor used for detecting Fe3+ and preparation method thereof

A potential sensor and optical addressing technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of complex preprocessing, long measurement cycle, and huge equipment, and achieve less sample solution, fast measurement, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Structure of the sensor

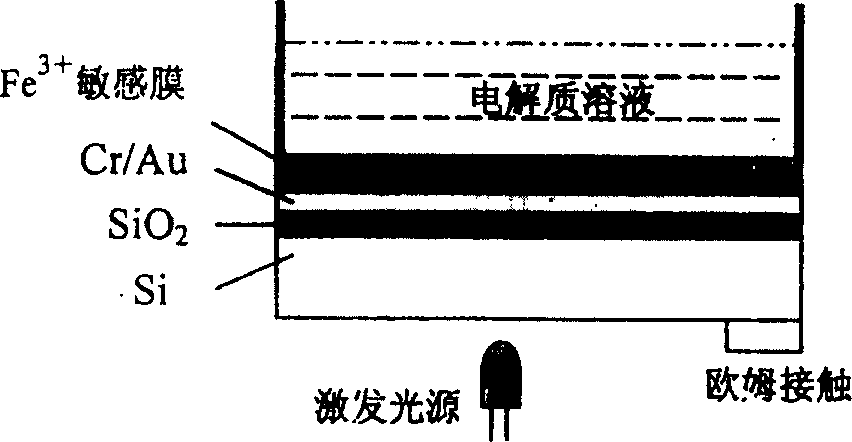

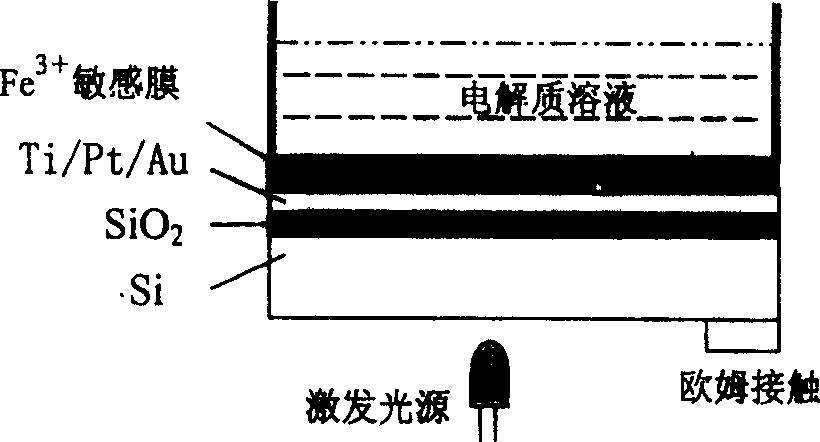

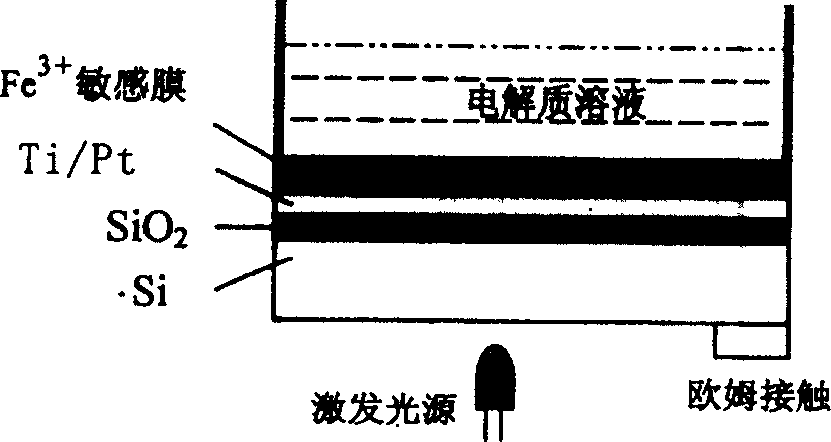

[0025] Use p-type or n-type Si sheets as the substrate, and there are SiO on the substrate from bottom to top. 2 layer, metal layer, for Fe 3+ sensitive film. The metal layer is Cr as the lower layer and Au as the upper layer, such as figure 1 shown; or the lower layer is Ti, the middle layer is Pt, and the upper layer is Au, such as figure 2 shown; or the lower layer is Ti, the upper layer is Pt, such as image 3 As shown; the excitation light source can be front or back lighting.

[0026] Preparation of sensors

[0027] (1) Preparation of LAPS

[0028] A p-type or n-type monocrystalline silicon wafer is selected as the substrate of LAPS. After the silicon wafer is polished and cleaned, it is placed in a high-temperature furnace for thermal oxidation, so that a layer of SiO with a thickness of about 30nm is grown on the front of the silicon wafer in dry oxygen. 2 Remove the oxide layer on the back of the silicon wafer by ion etching,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com