Optical head for scanning record carrier

A carrier and optical head technology, applied in optical recording head, recording/reproducing by optical method, system characterized by carrier structure, etc., can solve problems such as high cost of components and complex film lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

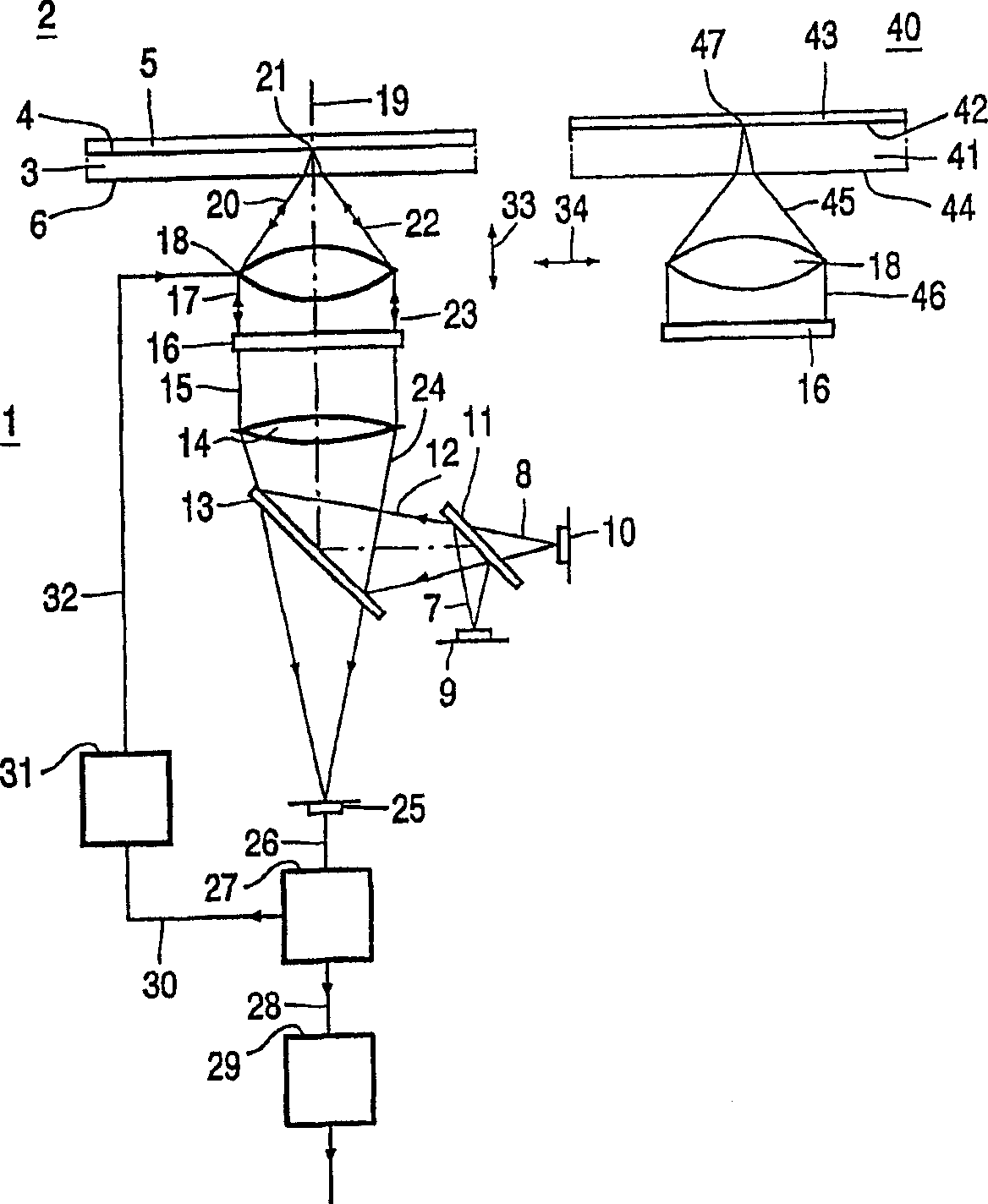

[0019] figure 1 A device 1 is shown for scanning an optical record carrier 2 of a first type and a record carrier 40 of a second type. In the illustrated embodiment, the first type is a DVD and the second type is a writable CD. The record carrier 2 comprises a transparent layer 3, on one side of which an information layer 4 is arranged. The side of the information layer facing away from the transparent layer is protected from environmental influences by a protective layer 5 . The side of the transparent layer facing the device is called the inlet face 6 . The transparent layer 3 acts as a substrate for the record carrier by providing mechanical support for the information layer. Alternatively, the transparent layer may have the sole function of protecting the information layer, while the mechanical support is provided by a layer on the other side of the information layer, for example by a protective layer 5 or by a further information layer and a transparent layer connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com