Improved object mfg. process

A technology of manufacturing process and process, applied in the field of object manufacturing, can solve problems such as consumption and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

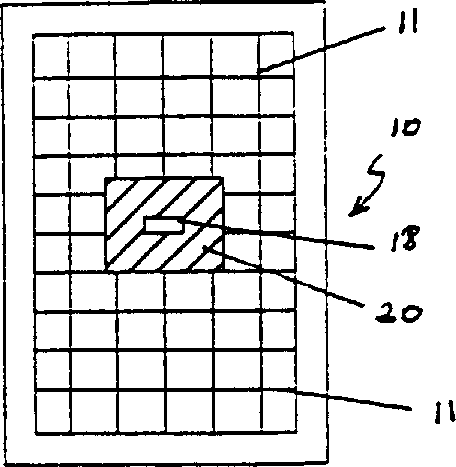

[0212] First, see figure 1 to Figure 5, figure 1 A page of paper 10 is shown, on which an outline 20 will be printed, and the outline 20 will become a part of the pyramid-shaped three-dimensional prototype 30 described in FIG. 10 is imprinted with a matrix of lines 11 dividing most of the remainder of the paper 10 into small squares, it being understood that cutting the paper 10 along the lines 11 will remove the remainder of the paper 10 around the outline 20.

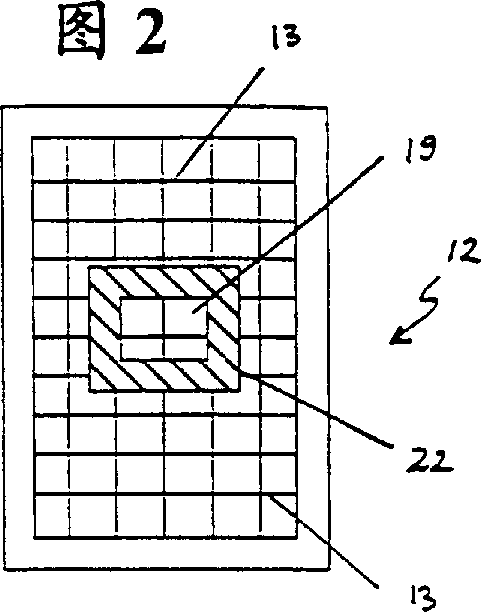

[0213] Figure 2 shows the second sheet of paper 12 with the outline printed on it Figure 22 , the size is slightly larger than the profile 20 of the paper 10, and the line matrix 13 is also printed on the paper 12, and the profile Figure 12 Most of the area outside the paper 12 is divided into small squares.

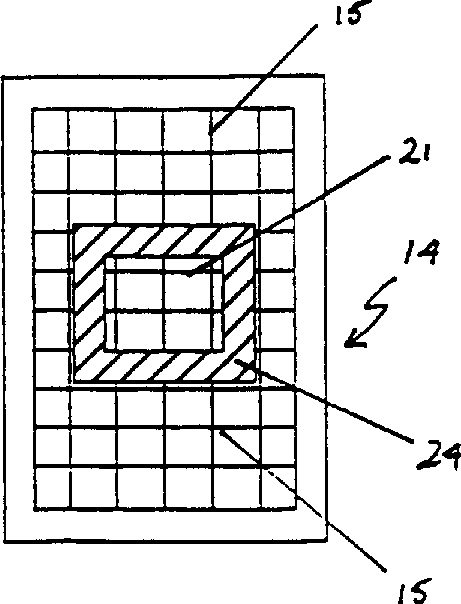

[0214] exist image 3 In , the contour map 24 on the paper 14 is slightly enlarged, the line matrix 15 is similar to the line matrix 13 in Fig. 2, and Fig. 4 shows that the paper 16 has a printed contour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com