Laminate having coextruded, multilayer film which delaminates and package made therefrom

A technology of laminated products and multi-layer films, applied in the field of packaging and packaging of red meat products, can solve the problems of pollution, soiling, film damage, etc.

Inactive Publication Date: 2000-03-01

CRYOVAC ILLC

View PDF3 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

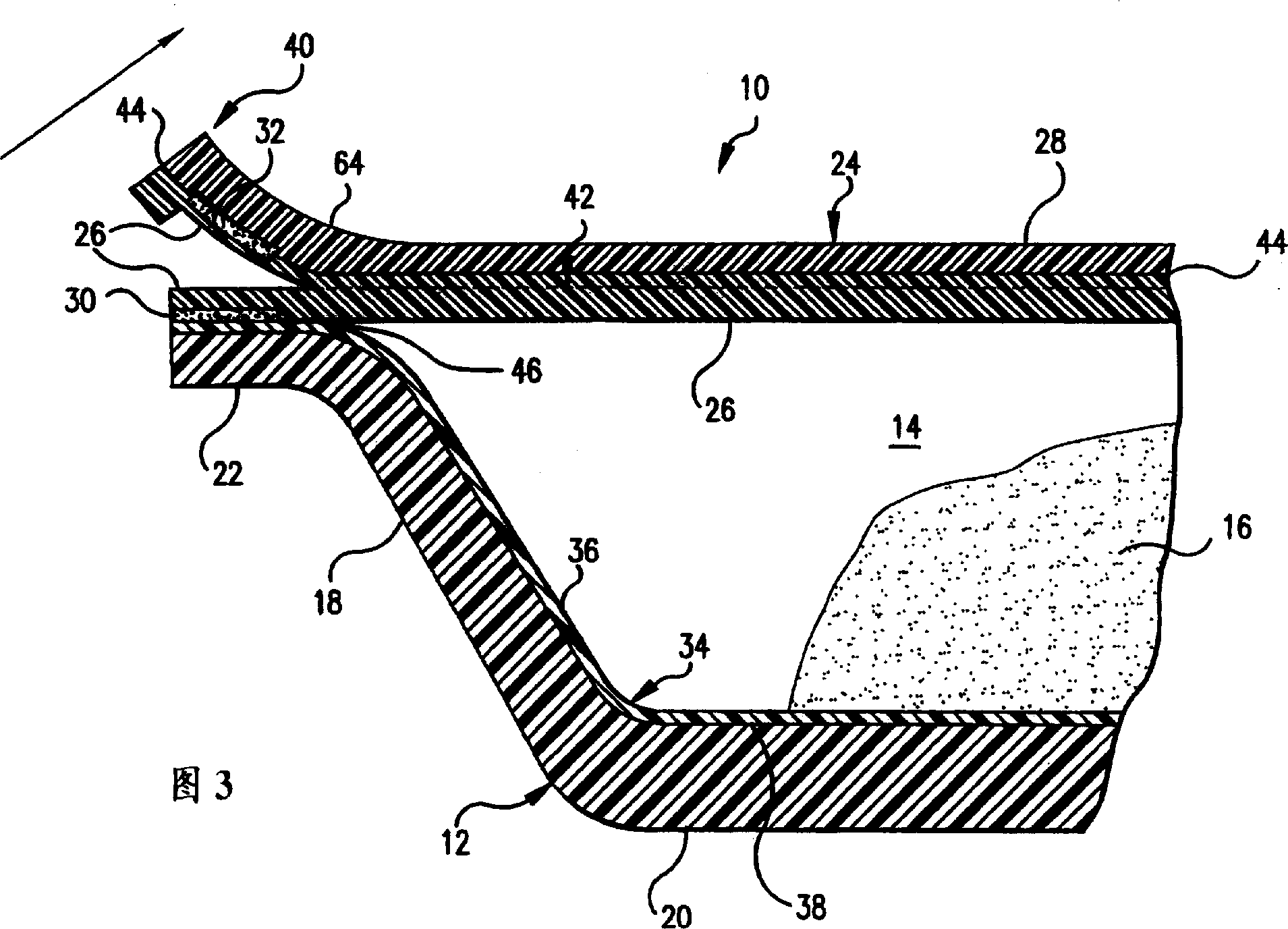

[0007] While a single, peelable cover has the advantage of providing a single edge for sealing to the edge of a conventional tray, such films often break during peeling, while the impermeable film is either difficult to separate from the permeable film, or the entire or part of the permeable film remains adhered to the impermeable film and is torn from the rest of the package, thereby creating cracks or small holes in the package that soil or contaminate the packaged meat product

The main difficulty lies in achieving consistent, reliable peelability in a single peelable cover of peelable and non-peelable films in an interbonded manner

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0105] # * PE / EVA 1 / PETG / TIE 1 / LLDPE 1 / LMDPE * # / / / / SiO x / PET (thickness is 2.35 mils)

Embodiment 2

[0107] # * PE / EVA 1 / PETG / TIE 1 / LLDPE 1 / LMDPE * # / / / / Saron / PET (thickness is 2.35 mils)

Embodiment 3

[0109] # * PE / EVA 1 / PETG / TIE 1 / LLDPE 1 / 25% LMDPE+25%EMA+50%LLDPE 1 * # / / / / Saron / PET (thickness is 2.35 mils)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

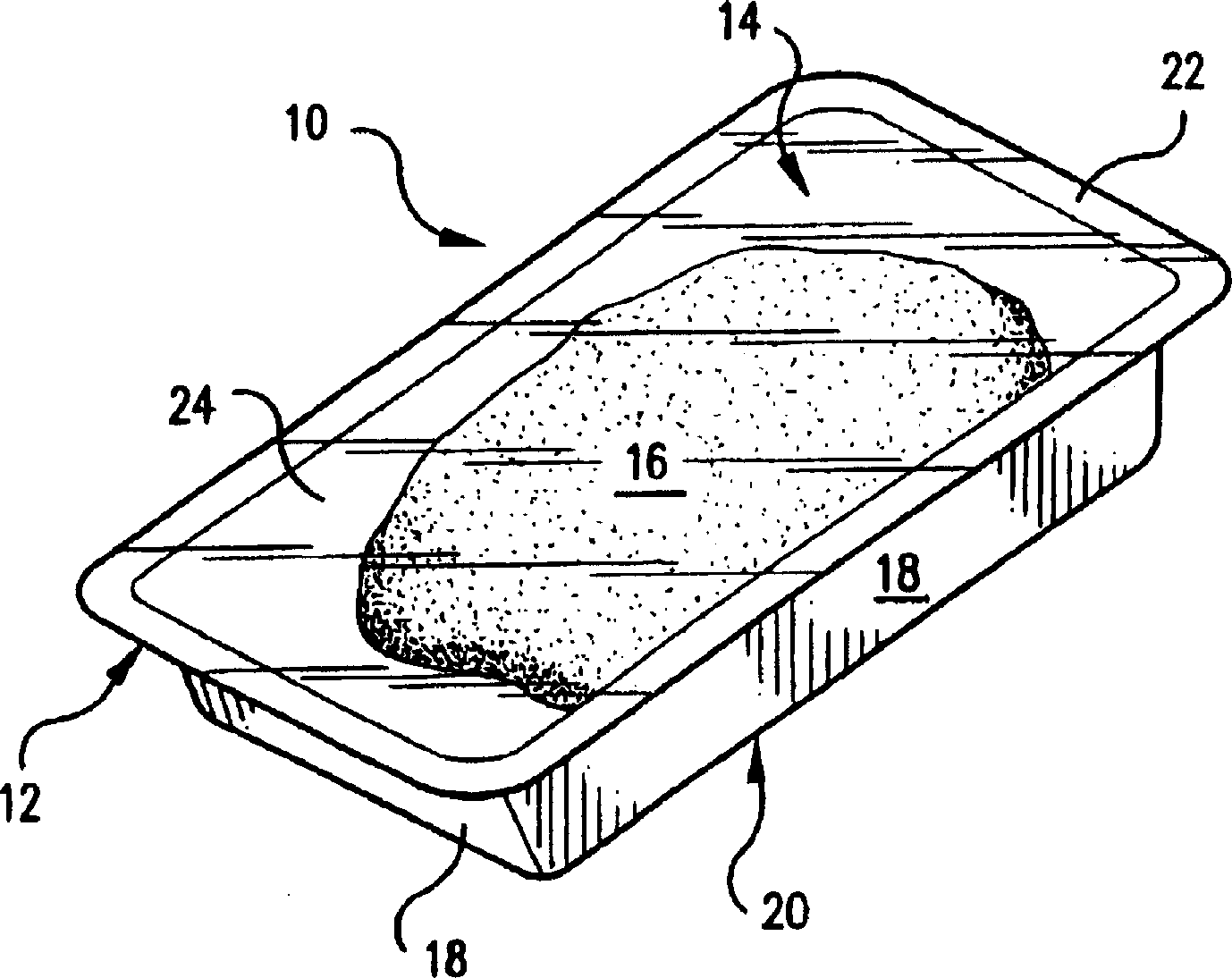

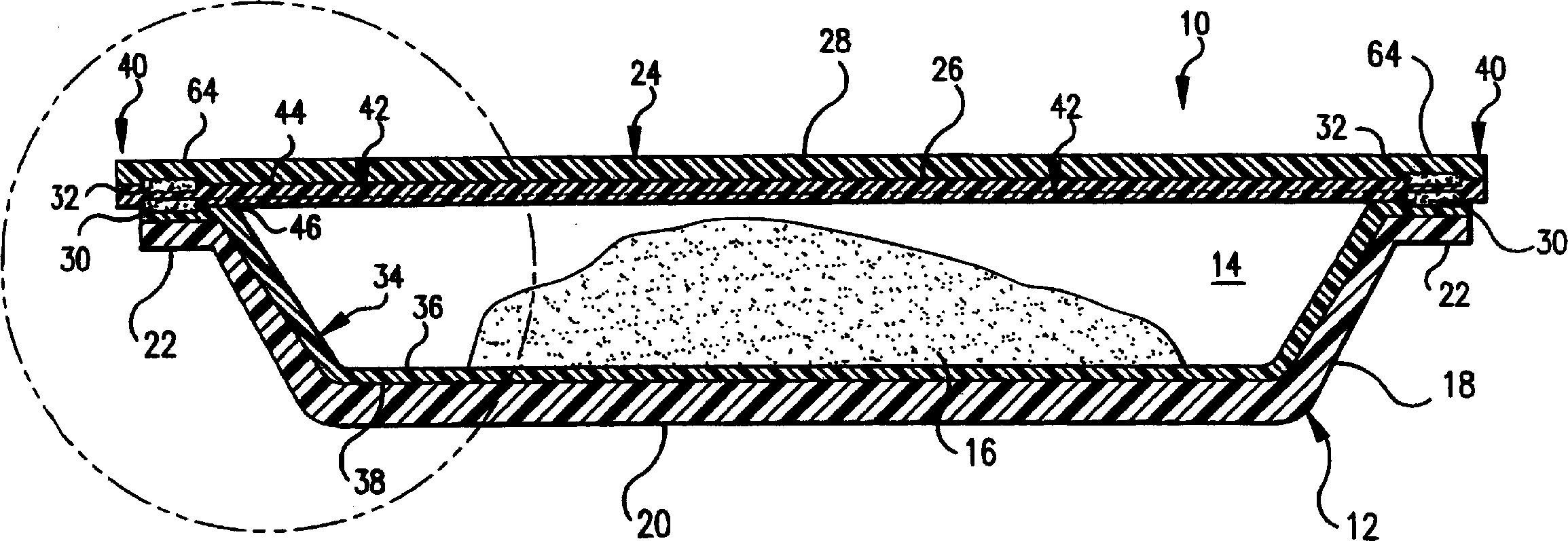

A laminate comprising two or more films (26, 28), at least one of the films being a coextruded, multilayer film (26), wherein the laminate delaminates within the coextruded, multilayer film (26) when the laminate is subjected to a peel force ranging from 0.001 to 2.5 pounds per inch. The laminate adavantageously provides the lid (24) for a package and delaminates into a substantially gas-impermeable portion and a gas-permeable portion, with the gas-permeable portion being bonded directly to a product support member (12) of the package. In this manner, the gas-impermeable portion may be peelably removed from the package to allow atmospheric oxygen to enter the interior of the package. The gas-permeable portion may be provided by perforating the delaminatable, coextruded film (26) and bonding such film to the support member (12) so that, when the laminate is caused to be delaminated within the perforated, coextruded film (26), the perforations are exposed to the ambient atmosphere, and thereby allow for rapid ingress of oxygen into the interior of the package.

Description

Background of the invention [0001] The present invention relates to packaging for, for example, food products which are enclosed under certain environmental conditions in a support with a lid which can be delaminated by peeling (i.e., comes off when peeled) to expose Outgassing permeates the film, thereby causing a change in the environmental conditions within the package. More particularly, the present invention relates to packaging for fresh red meat products. [0002] Historically, meat has been cut and packaged in larger pieces in every supermarket. Such solutions have long been considered inappropriate and costly. The best approach is to instead cut and pack the meat at a central plant, which has the advantage of being more economical in scale, and sell the packaged meat to individual supermarkets or other outlets, such as many poultry products like that. It is believed that the centralized processing of the domestic product also improves the quality, resulting in a m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B32B7/06B32B27/08B65D77/20B65D81/20

CPCB65D77/2024B65D81/2076Y10T428/14Y10T428/24331Y10T428/1379Y10T428/31507Y10T428/31757B65D2565/388Y10T428/3192Y10T428/31913Y10T428/31504B65D2577/2091Y10T428/31797Y10T428/31746B65D81/20B65D2577/2025Y10T428/1383B32B7/06B32B27/08Y10T428/1341Y10T428/2419Y10T428/2826B32B27/36B32B2307/724B32B27/40B32B27/32B32B27/34B32B2307/748B32B27/286B32B2439/00B32B2439/02B32B2307/7242B32B2307/514B32B27/308B32B27/306B32B27/304

Inventor P·N·科克K·A·穆达W·B·米勒H·W·斯托克莱三世

Owner CRYOVAC ILLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com