Automatic on line detecting device of hollow fiber separating membrane

A fiber separation and detection device technology, applied in the direction of semi-permeable membrane separation, membrane technology, analysis materials, etc., can solve the problems of short service life, inaccuracy, and quality limitation of instrument accuracy, etc., to improve filtration quality and measurement data Accurate, low labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

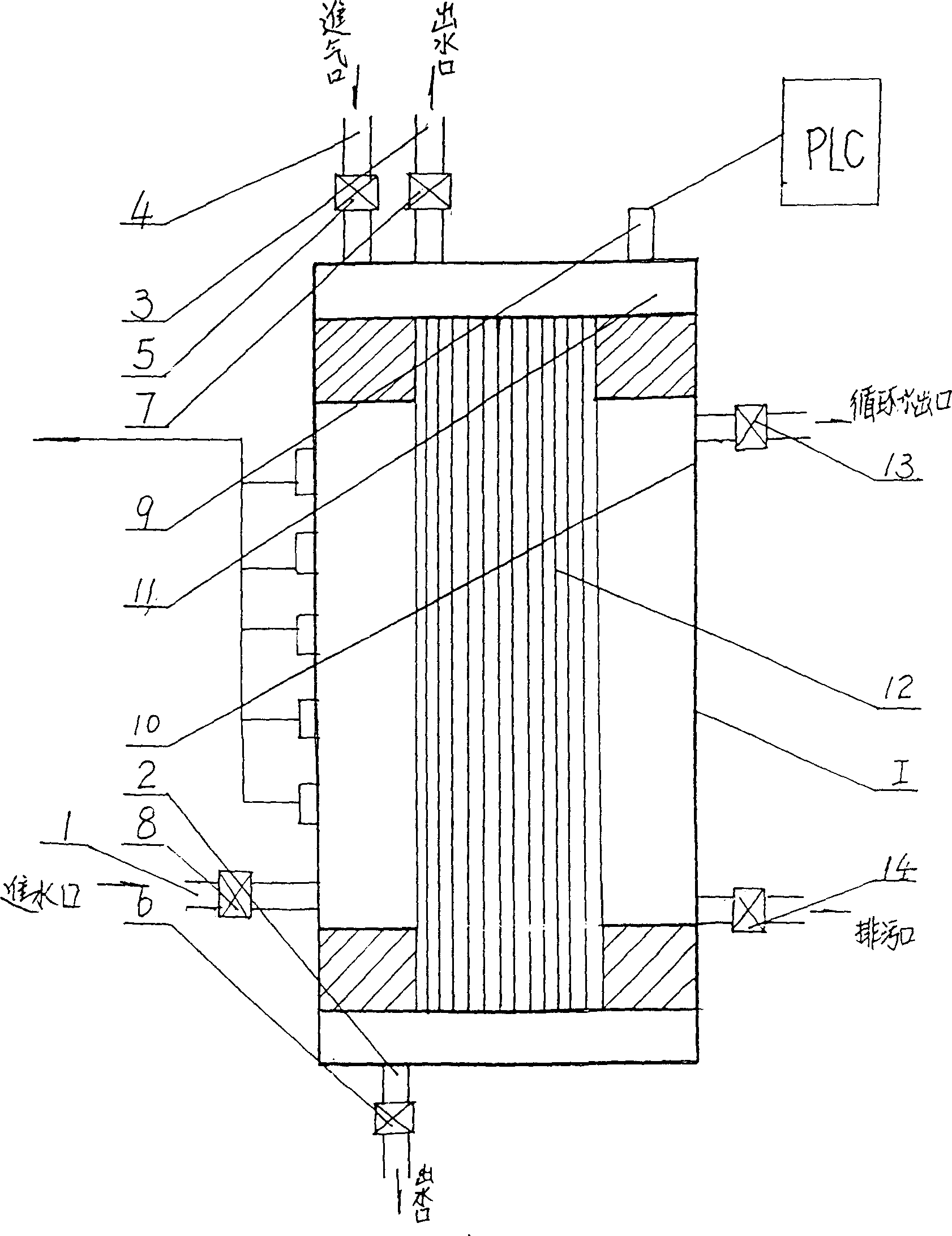

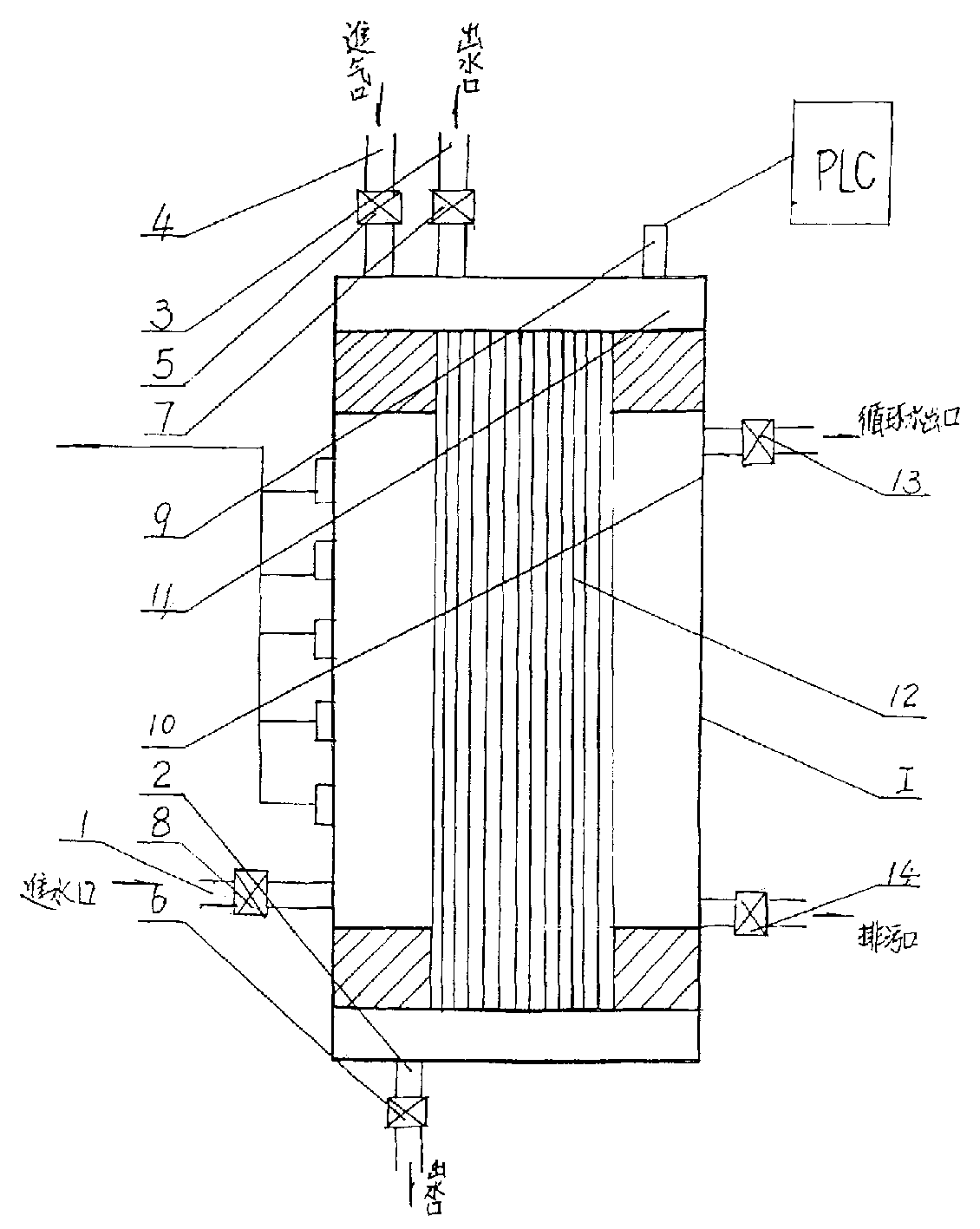

[0007] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are exemplified and detailed descriptions are as follows in conjunction with the accompanying drawings, please refer to figure 1 .

[0008] Such as figure 1 As shown: an air inlet 4 is provided above the hollow fiber separation membrane module shell 10, and an air inlet valve 5 is installed on it, and a pressure sensor 9 is fixed on the upper end of the separation membrane module shell 10 and communicated with the water outlet 11. During work, the sewage enters the separation membrane assembly I from the water inlet 1 of the separation membrane assembly I through the valve 8. When the external pressure type is used, the sewage enters from the small holes on the separation membranes 12, and the filtered clean water flows from the separation membrane assembly. I Water outlets 2 and 3 flow out through valves 6 and 7, and a test is carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com