Non oriented electric steel plate without corrugated fault and its making process

An oriented electrical steel sheet, non-corrugated technology, applied in the direction of metal rolling, etc., can solve the problems such as the inclusions in the mold are not easy to float, the reduction rate of the last pass of rough rolling is large, and the operation of finishing rolling is affected. The effect of normalizing the rolling process, eliminating corrugated defects and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

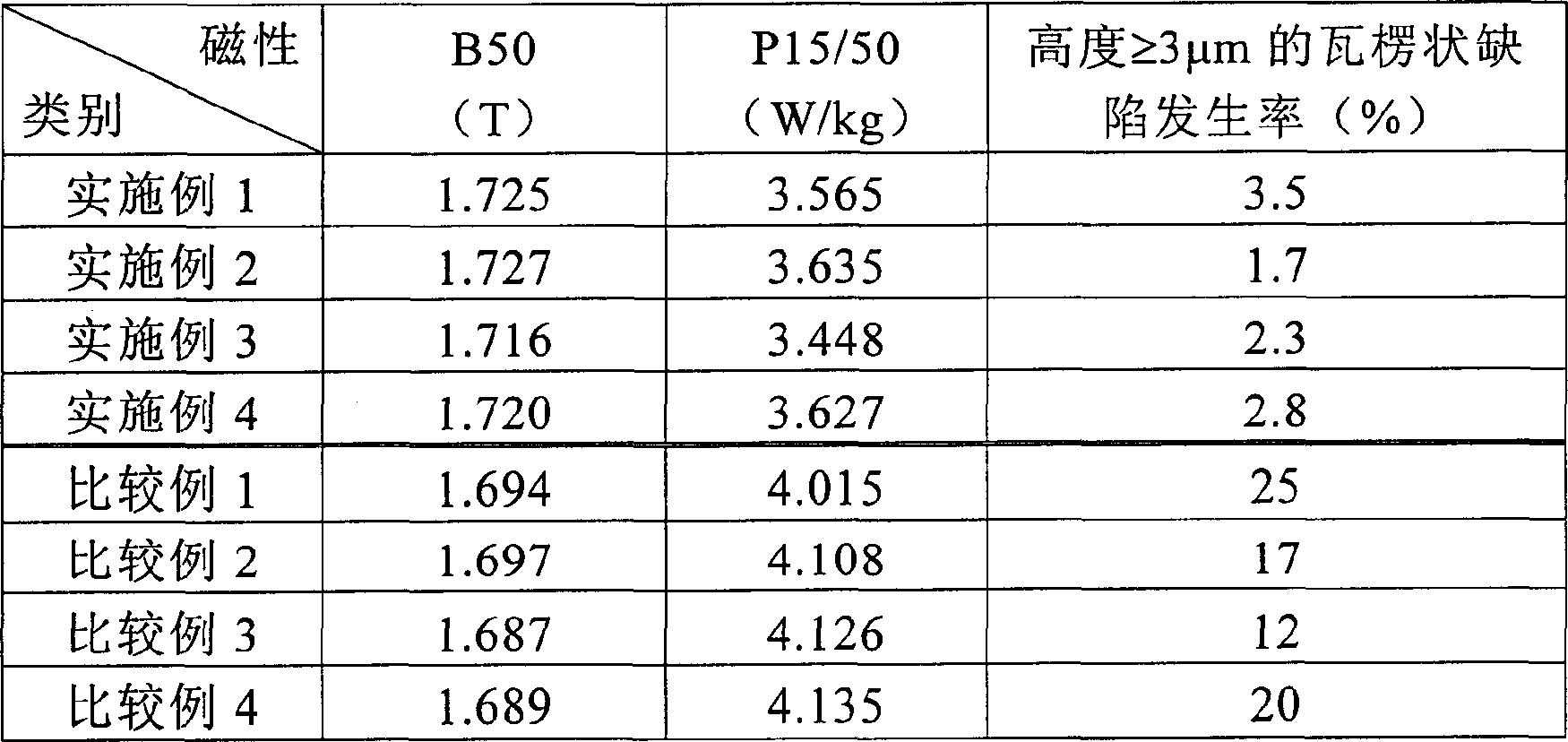

[0039] Smelt according to the components in Table 1, and obtain continuous casting slabs by continuous casting; then the continuous casting slabs are heated, rough rolled, and rough rolled for 4 passes, 25%→25%→40%→45% reduction rate / pass The final rough rolling temperature is 988°C; then finish rolling, the second pass of finish rolling is finished rolling with a roll with a roughness of 7 μm, and the hot-rolled sheet after finish rolling is coiled at a temperature of 710°C. There are no corrugated defects with a height of ≥3 μm in the finished board, and the magnetic properties are: B50=1.725T, P15 / 50=3.565W / kg.

Embodiment 2

[0041] Smelt according to the components in Table 1, and obtain continuous casting slabs by continuous casting; then the continuous casting slabs are heated, rough rolled, and rough rolled for 4 passes, 25%→30%→40%→40% reduction rate / pass The second time, the finishing rolling temperature of the rough rolling was 992°C, the second pass of the finish rolling was finished rolling with a roll with a roughness of 7 μm, coiled at 710°C, no corrugated defects with a height of ≥3 μm appeared in the finished plate, and the magnetic properties were: B50= 1.727T, P15 / 50=3.635W / kg.

Embodiment 3

[0043] Smelt according to the components in Table 1, and obtain continuous casting slabs by continuous casting; then the continuous casting slabs are heated, rough rolled, and rough rolled for 4 passes, 25%→30%→40%→40% reduction rate / pass The second time, the finishing rolling temperature of the rough rolling was 1002°C, the roll with a roughness of 7μm was used for the second finish rolling, and the coil was coiled at 710°C. There was no corrugated defect with a height of ≥3μm in the finished plate, and the magnetic properties were: B50=1.716T , P15 / 50=3.448W / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com