Electric aircraft

An aircraft and electric technology, applied in the field of aviation aircraft, can solve problems such as propeller failure, loud noise, and high-altitude air pollution, and achieve good flight stability, avoid complex structures, and low flight noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

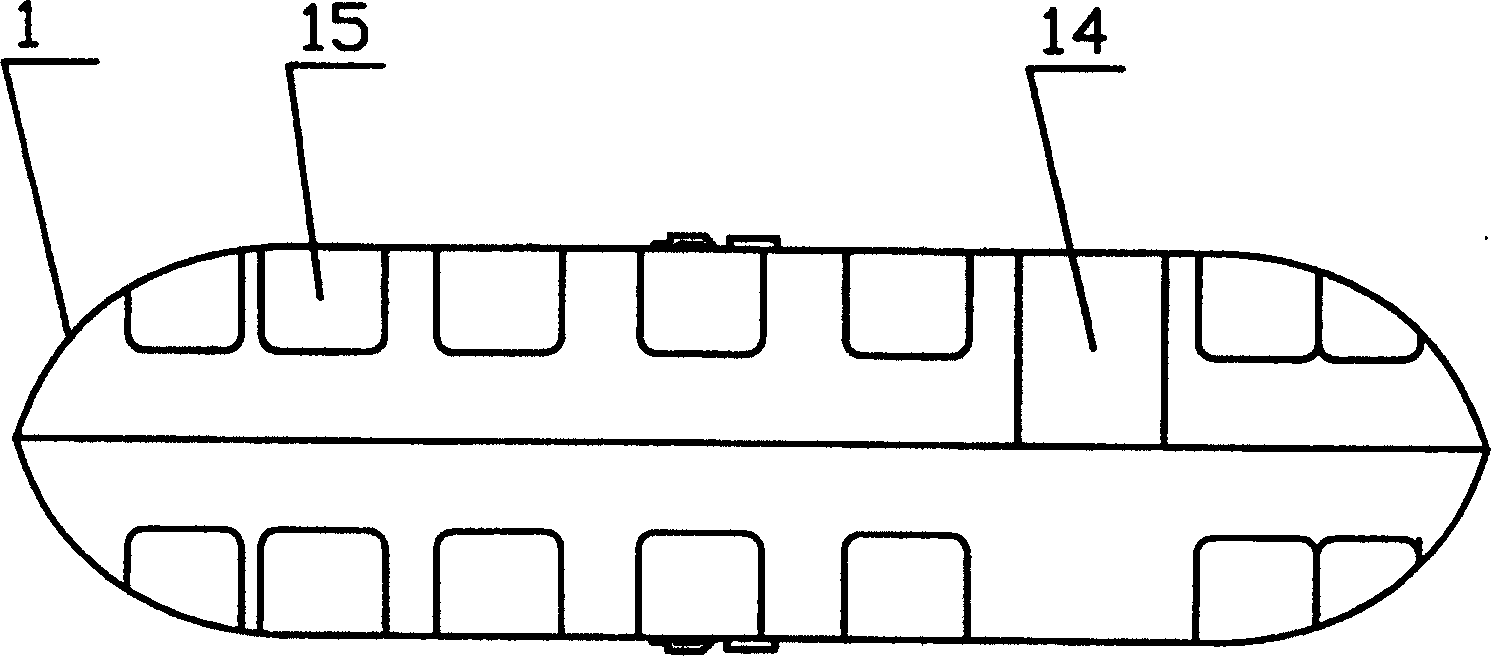

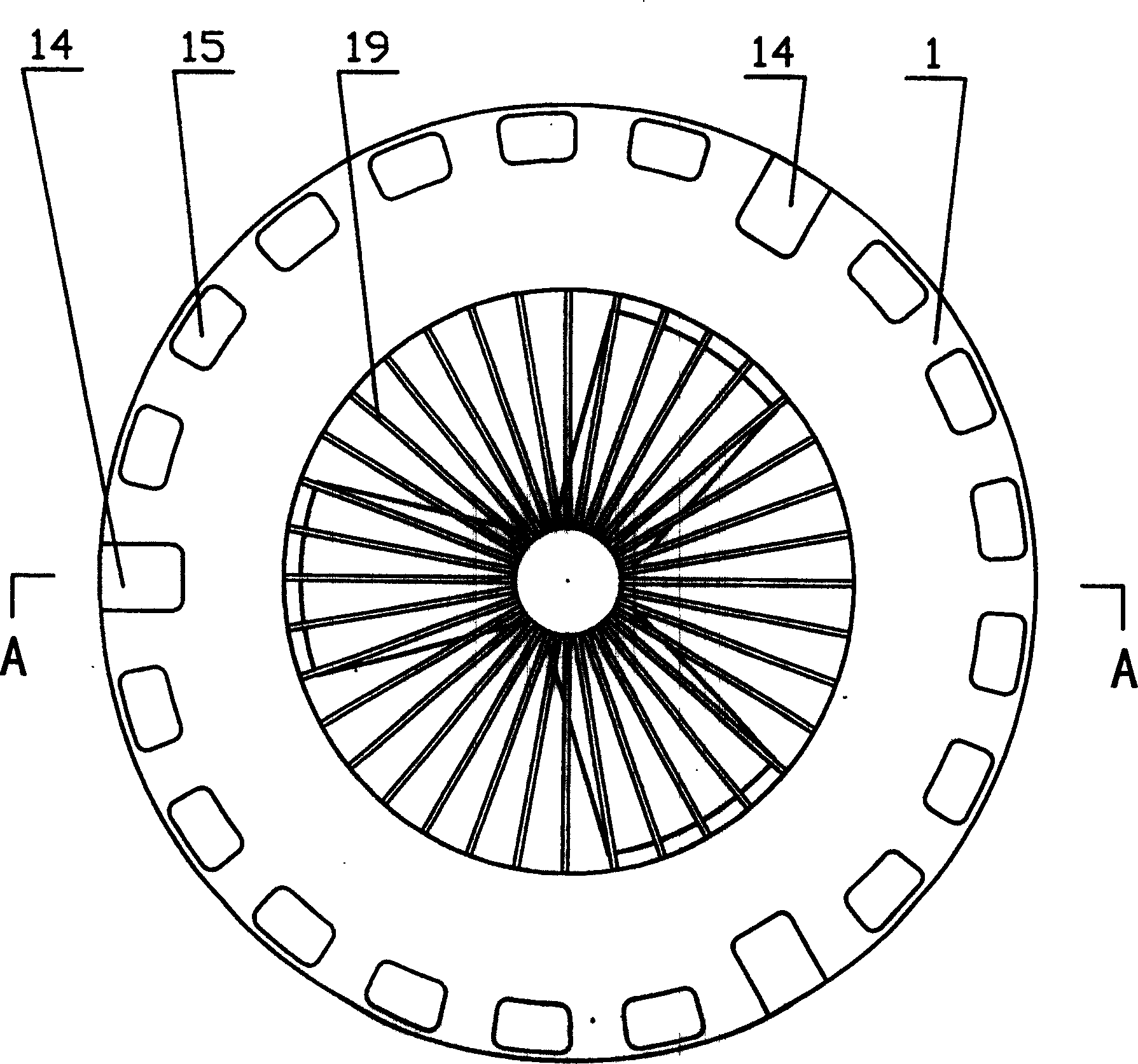

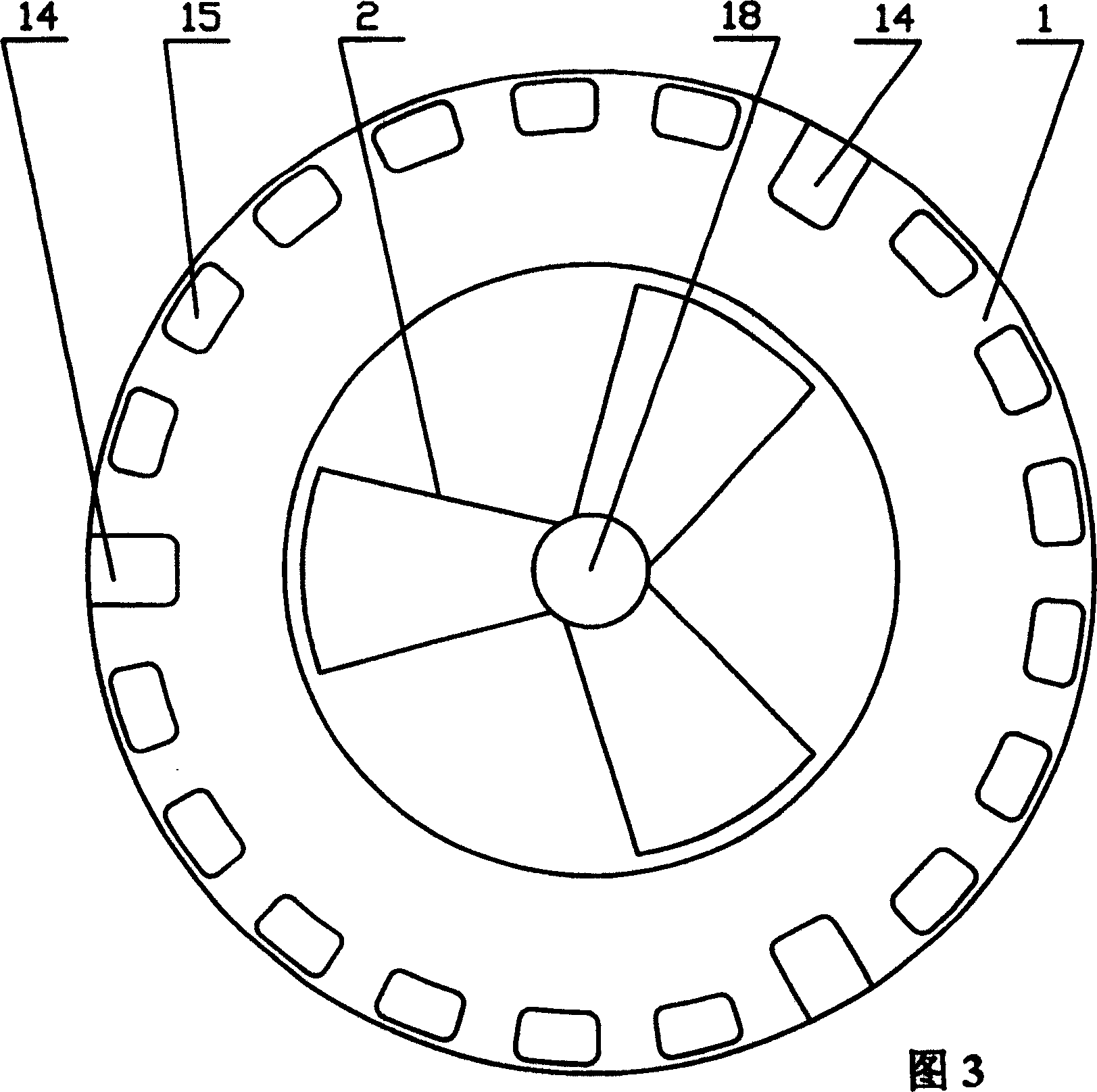

[0018] Drawing No.:

[0019] 1. Ring shell 2. Upper flying wing group 3. Lower flying wing group

[0020] 4A. Upper circular guide rail (the upper guide rail in the upper circular guide rail)

[0021] 4B. Upper circular guide rail (the lower guide rail in the upper circular guide rail)

[0022] 5A. Lower circular guide rail (the upper guide rail in the lower circular guide rail)

[0023] 5B. Lower circular guide rail (the lower guide rail in the lower circular guide rail)

[0024] 6. Passenger compartment 7. High-speed motor 8. Main shaft 9. Roller

[0025] 10. Central shaft 11. Bearing 12A. Conductive ring 12B. Conductive ring

[0026] 13A. Conductive ring 13B. Conductive ring 14. Door 15. Window

[0027] 16. Passenger 17. Channel 18. Cover 19. Spokes

[0028] 20. Cover 21. Spokes 22. Power cord 23. Power cord

[0029] 24. Connecting plate 25. Bolt 26. Longitudinal I-shaped rib

[0030] 27. Horizontal I-shaped rib 28. Skin 29. Bearing

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com