Spraying and diffusing combustion system of IC engine

A combustion system, diffusion technology, applied in the direction of internal combustion piston engine, charging system, combustion engine, etc., can solve the problems of uneven spray, short penetration distance of umbrella spray, and excessively concentrated circumferential distribution of the mixture, and achieve the spray dispersion speed. The effect of fast, large distribution space, and light exhaust smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

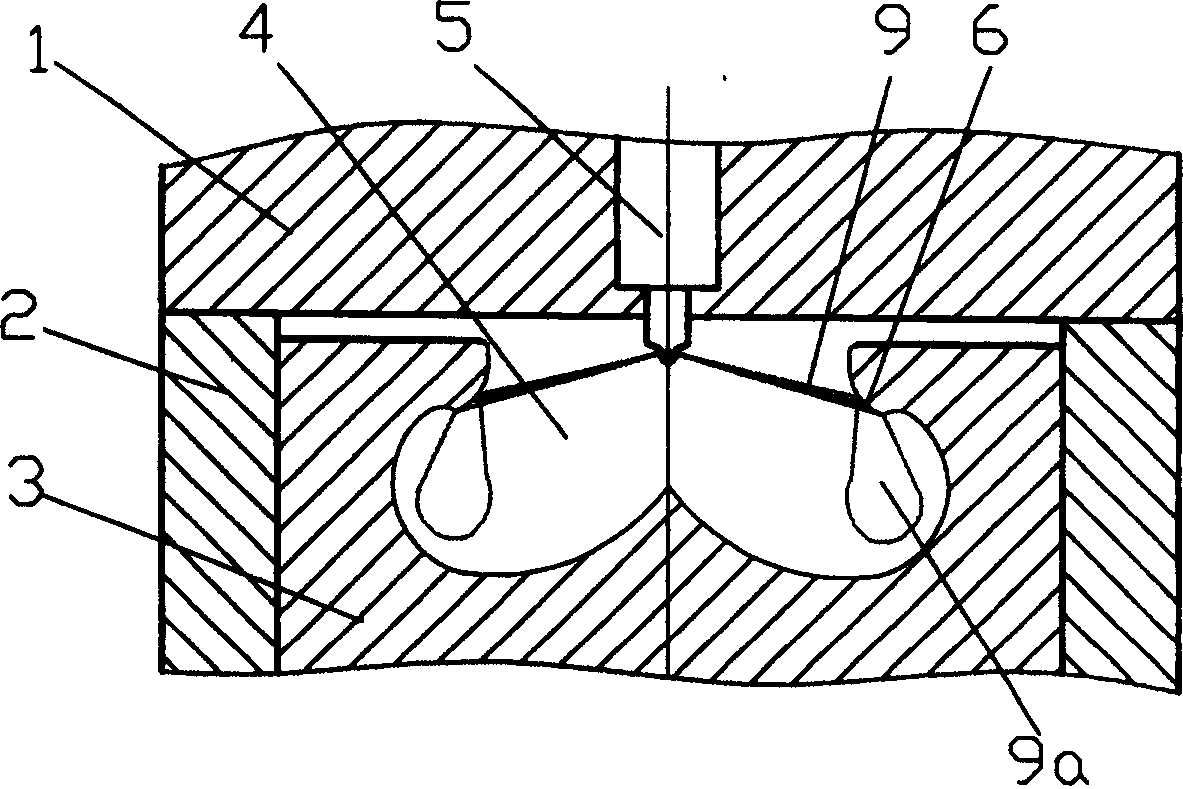

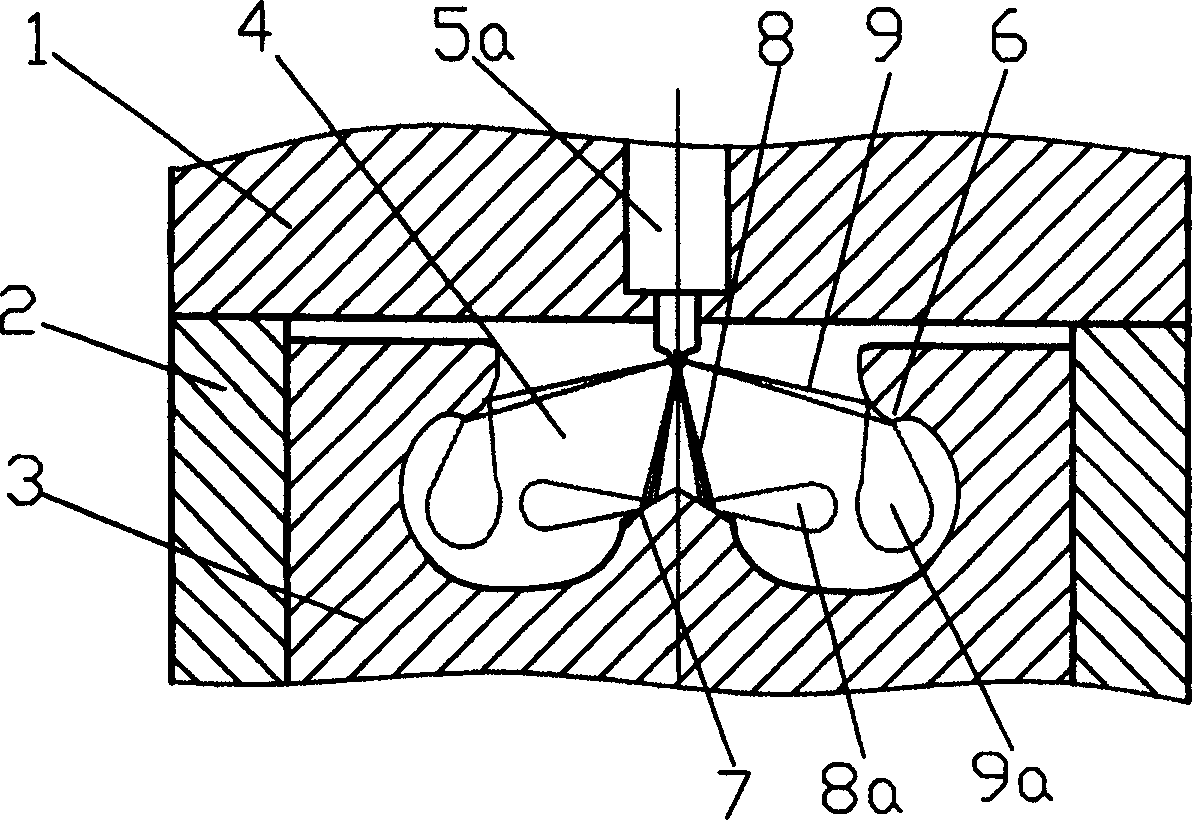

[0010] exist figure 1 , 2 , In the shown embodiment, a main combustion chamber is composed of cylinder head 1, cylinder liner 2 and piston 3, and the combustion chamber 4 located on the top of the piston should cooperate with the oil beam of the injector. The spray diffusion surface provided at the closing part is an arc surface, and the oil beam 9 of the injector is directly sprayed to the arc surface.

[0011] exist figure 1 Among them, the spray diffusion surface at the closing of the combustion chamber 4 adopts the circular arc surface 6, and the oil beam 9 of the single-row nozzle injector 5 is directly sprayed to the circular arc surface 6 to form a diffused oil beam 9a with a wider distribution range.

[0012] exist figure 2 Among them, the spray diffusion surface at the mouth of the combustion chamber 4 also adopts an arc surface 6, and a protrusion with a conical surface 7 is also provided in the center of the combustion chamber 4. The oil beam 9 of the upper row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com