Collision spray burning system of internal combustion engine

A technology of combustion system and internal combustion engine, which is applied in the direction of internal combustion piston engine, charging system, combustion engine, etc. It can solve the problems of short penetrating distance, unevenness of umbrella-shaped spray, and too thick circular distribution of mixed gas, so as to achieve fast spray dispersion speed , improved emission indicators, and a large spatial range of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

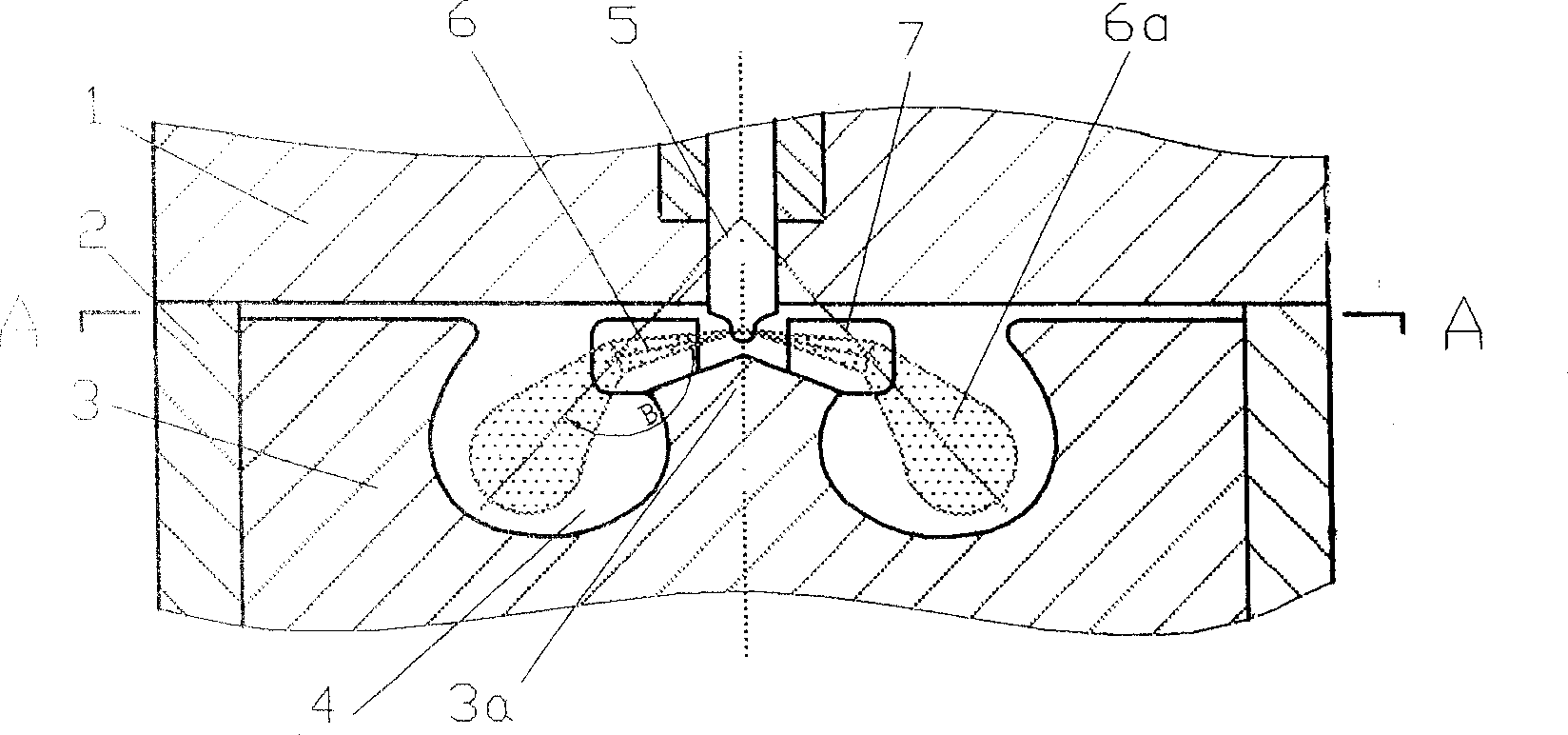

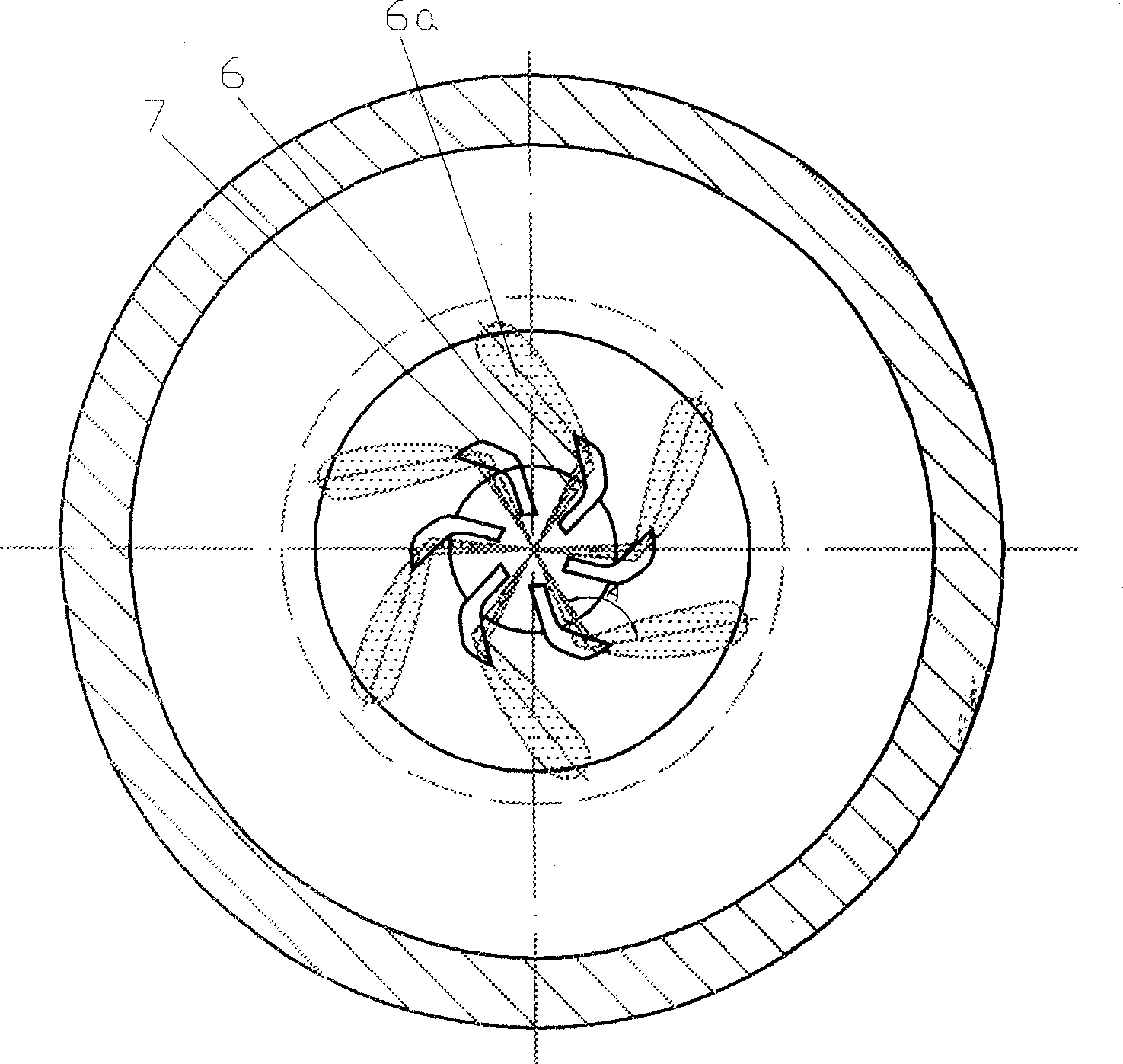

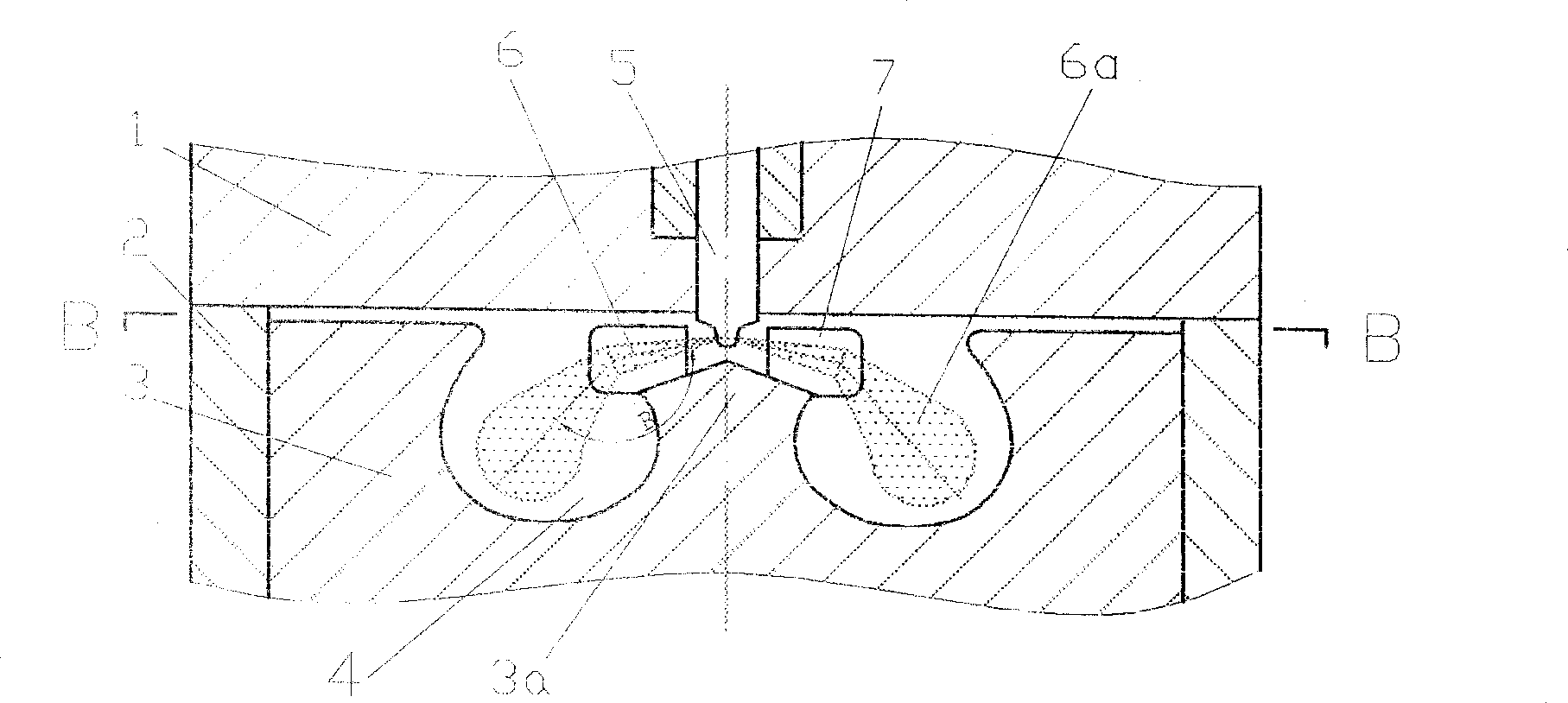

[0012] exist figure 1 , 2 In the shown embodiment, the combustion chamber 4 composed of the cylinder head 1, the cylinder liner 2 and the piston 3 is provided with 6 collision blocks 7 on the central boss 3a of the piston 3, and the 6 primary fuel injection nozzles 5 After the jets 6 are directly sprayed onto the corresponding six collision blocks 7, six evenly distributed secondary oil jets 6a are formed in the combustion chamber 4. The profile of the oil beam collision area of each collision block 7 can make the angle between the center line of the secondary oil beam 6a in the longitudinal direction and the primary oil beam be about 140 degrees, and the secondary oil beam in the radial direction and the primary oil beam The angle between the centerlines of the bundles is about 110 degrees. The secondary oil beam 6a should expand along the air flow, and adjust the longitudinal angle B and radial angle A of the centerlines of the primary oil beam 6 and the secondary oil be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com