Squeeze-flow combustion chamber of internal combustion engine

A technology for combustion chambers and internal combustion engines, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of short penetrating distance, unevenness of umbrella-shaped spray, and too thick circular distribution of the mixed gas, so as to achieve fast spray dispersion speed, Improvement of emission indicators and the effect of a large spatial range of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

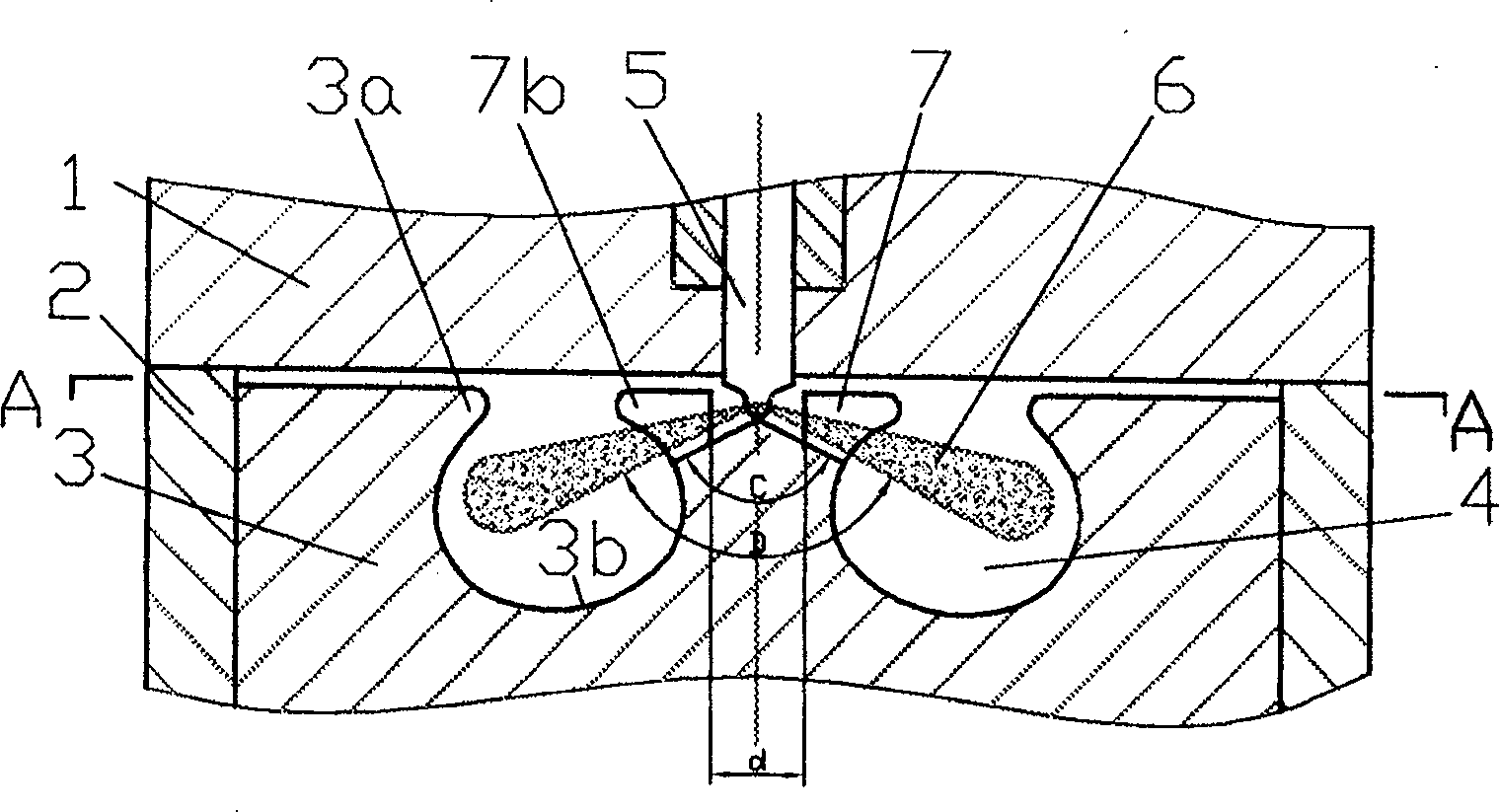

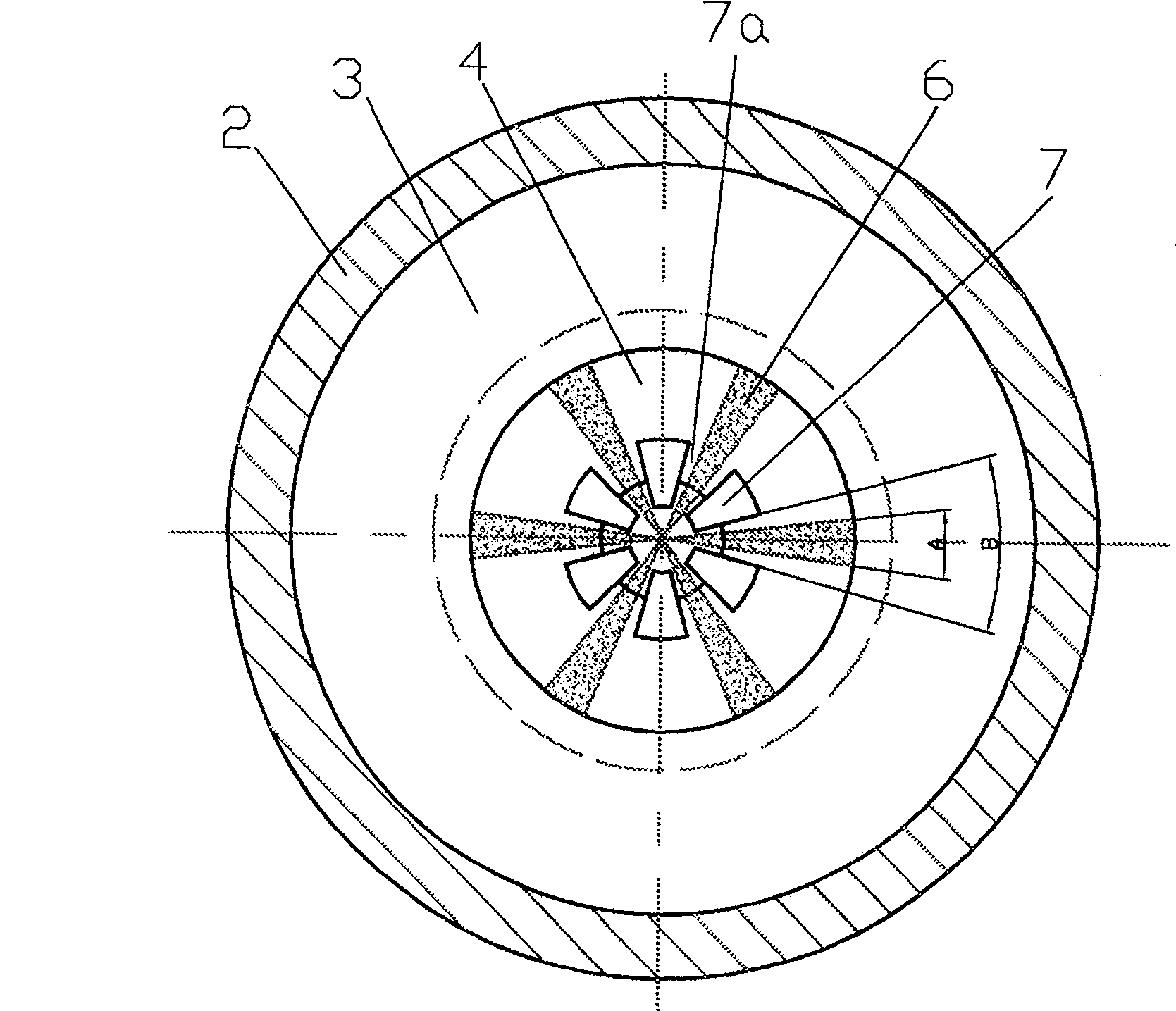

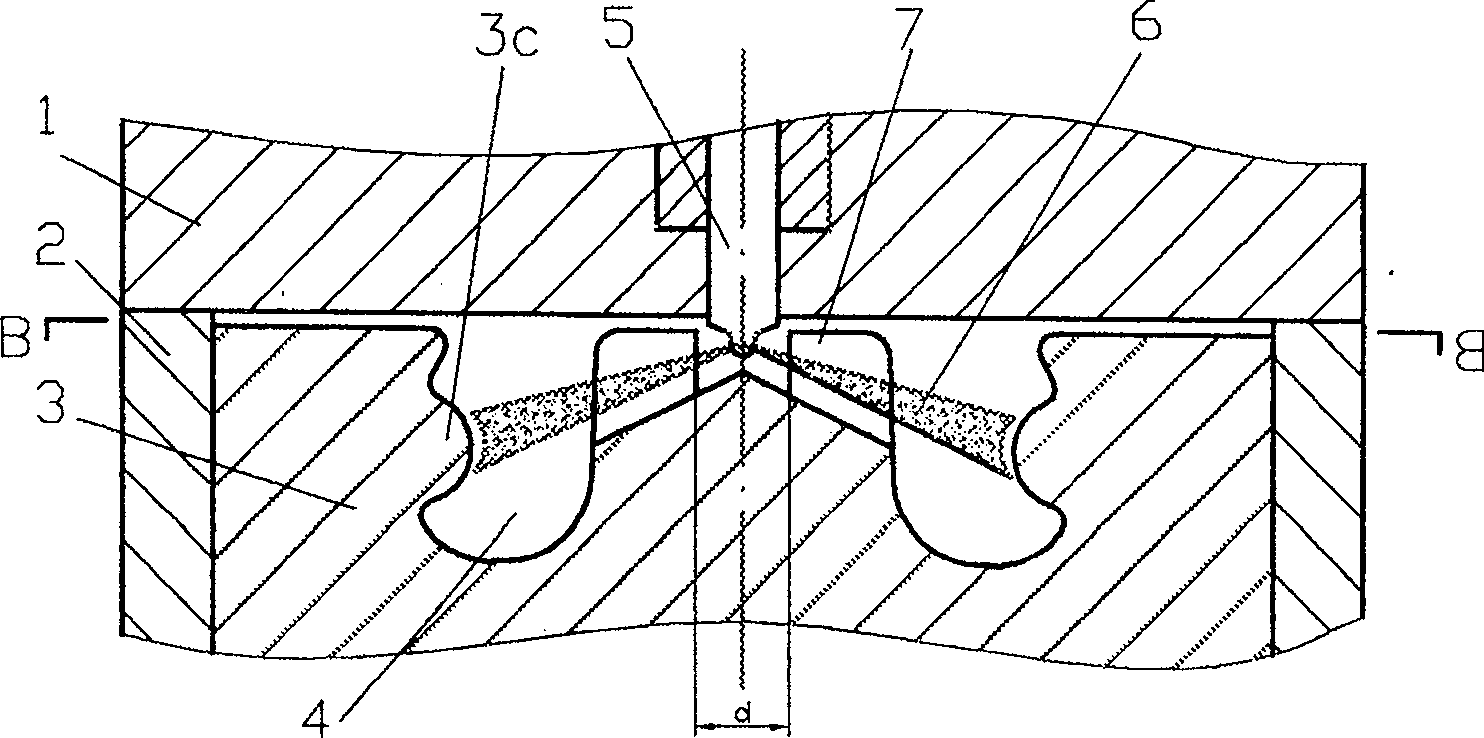

[0012] exist figure 1 , 2 In the shown embodiment, there is a combustion chamber 4 composed of a cylinder head 1, a cylinder liner 2 and a piston 3, and a squish platform 7 is arranged at the center of the piston 3, and the upper plane of the squash platform 7 is in contact with the top surface of the piston 3. flush, and there are fan-shaped grooves 7a on the squeeze platform 7, and the six oil jets 6 ejected from the fuel injector 5 just enter the combustion chamber 4 from the six fan-shaped grooves 7a. The upper part is provided with an outer closing port 3a, and the top of the squeeze platform 7 is provided with an inner closing port 7b. The two closing ports 3a, 7b and the inner wall arc 3b of the combustion chamber 4 form a mixing area where oil and gas are concentrated. In order to prevent the oil beam 6 from colliding with the wall in the fan-shaped groove 7a, it is required that the fan-shaped angle B should be greater than the atomization cone angle A of the oil bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com