Prepn. process for magnetic core solenoidal microinduction element of micro-electromechanical system

A micro-electromechanical system and micro-inductance technology, applied in the field of microelectronics, can solve problems such as the influence of coil and magnetic core performance, high curing temperature of insulating materials, and difficulty in obtaining high-performance micro-inductance devices, etc. The effect of solving the circuit breaker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

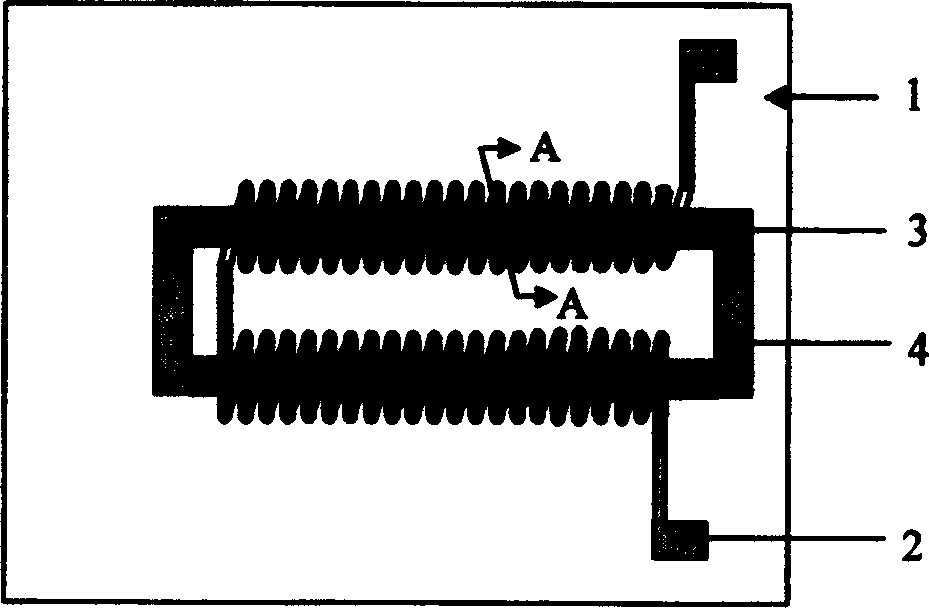

[0050] Micro-inductance device structure of the present invention such as figure 1 As shown, it is composed of substrate 1, pin 2, solenoid coil 3, and magnetic core 4. The solenoid coil 3 is based on the substrate 1, and two groups of connected three-dimensional coils are symmetrically wound around the rectangular closed magnetic core 4. A three-dimensional solenoid coil 3 , the two ends of the solenoid coil 3 are connected to the pin 2 .

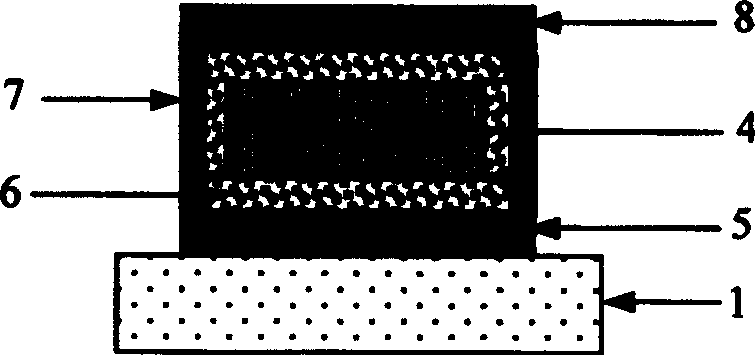

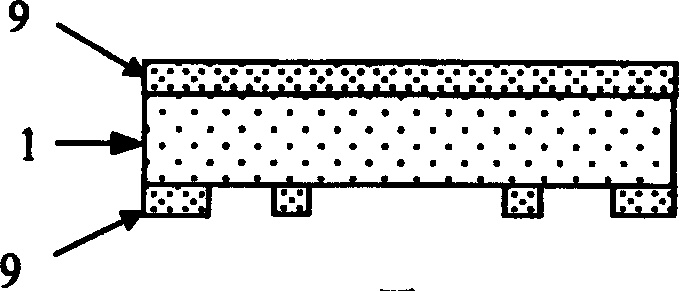

[0051] figure 2 for figure 1 The sectional view of the structure along the direction A-A shows the longitudinal three-dimensional structure of the solenoid coil 3 of the present invention. like figure 2 As shown, the bottom coil 5 is arranged on the plane of the substrate 1, and the three-dimensional solenoid coil 3 is surrounded by the magnetic core 4. The solenoid coil 3 is formed by connecting the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com