High-speed T-shaped associated tooth root wrapping tooth top type anti-drop rubber caterpillar

A technology of rubber track and dedendum, which is applied in the field of high-speed 'T' type associated dedendum wrapping tooth top type anti-detachment rubber track, which can solve the problem of affecting the structure and arrangement of the wheel train, the heavy weight of the main body of the rubber track, and double-sided drive To eliminate tooth root peeling and other problems, achieve the effect of eliminating track tooth undercutting, increasing installation and layout space, and simplifying tooth structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

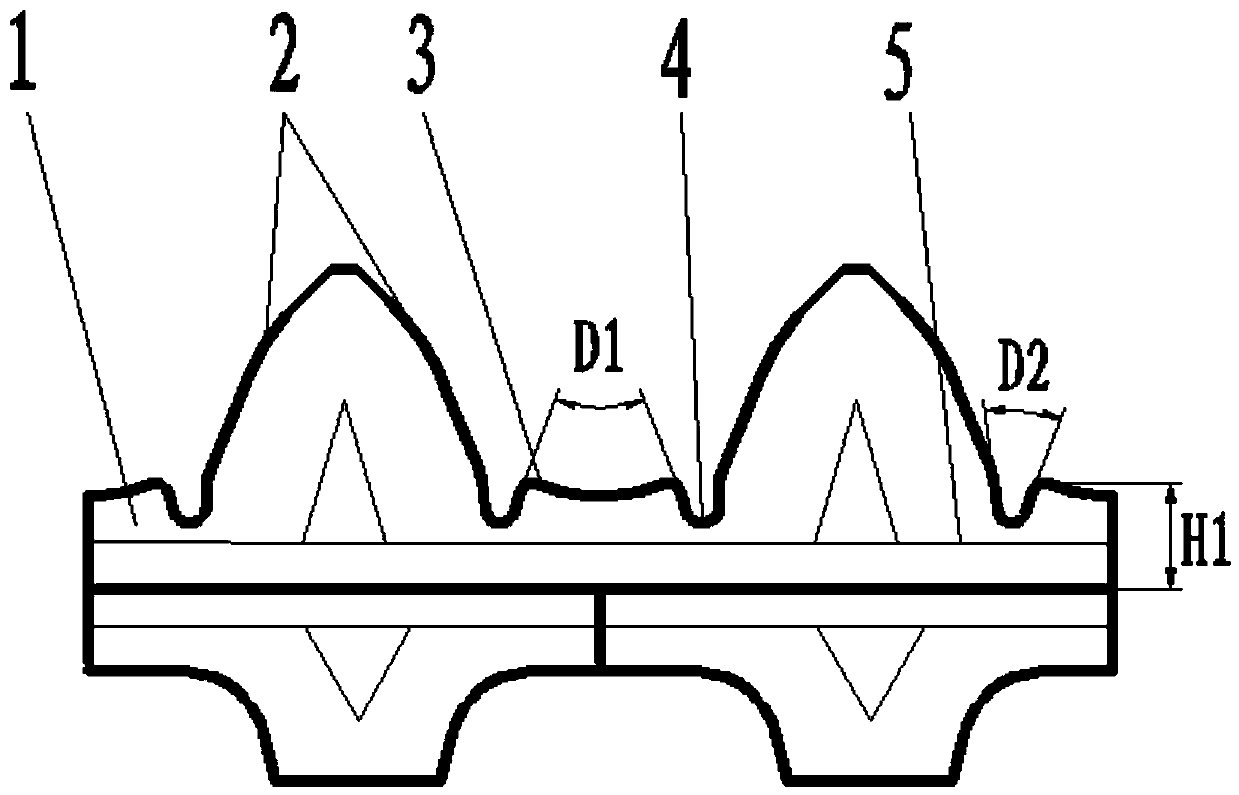

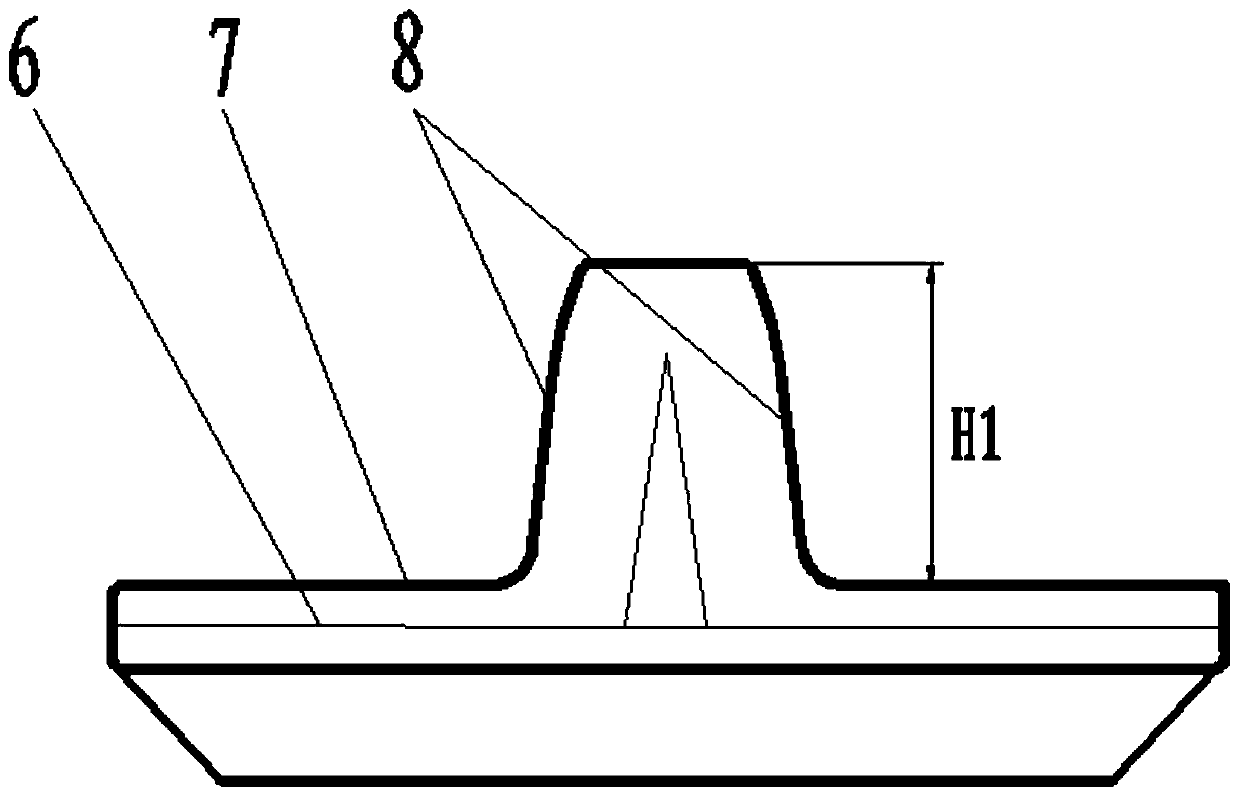

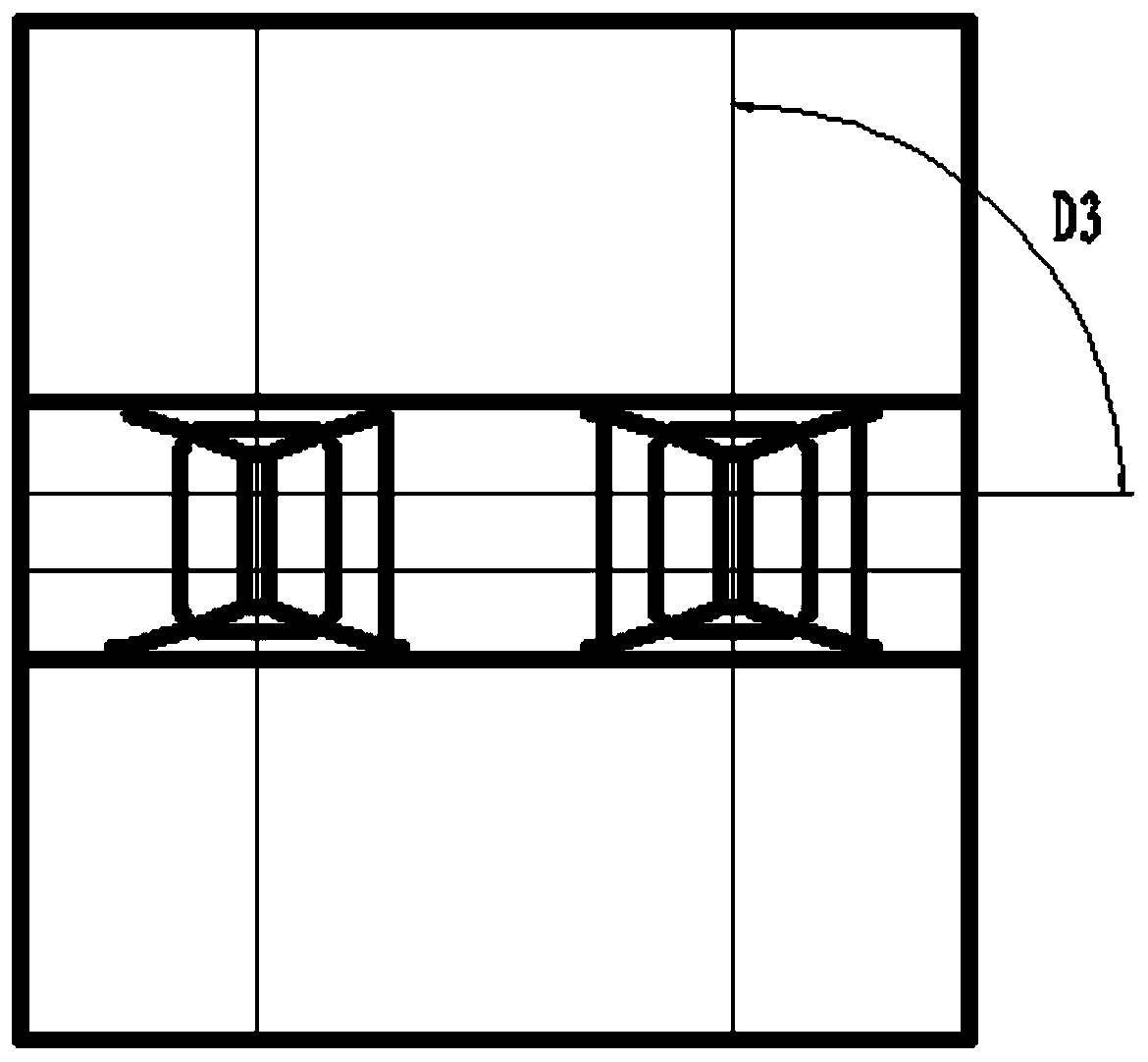

[0016] A kind of high-speed 'T' type associated dedendum wrapping tooth top anti-detachment rubber track involved in this embodiment, such as figure 1 , figure 2 , image 3 As shown, the track includes a rubber main body 1, an integrated guide rubber tooth bearing surface 2 on both sides, an associated tooth root meshing surface 3, a tooth root arc groove 4, an integrated non-metallic longitudinal fiber-pulling tooth flap 5, an integrated Non-metallic transverse fiber-toggle flap 6, load-bearing surface 7, inwardly inclined double-sided guide surface 8, tooth root correlation height H1, guide height H2, arc surface meshing angle D1, single-tooth bending angle D2, fiber-toggle flap arrangement angle D3; characterized in that: the arc meshing angle D1 of the associated dedendum meshing surface 3 is 40°; the single-tooth bending angle D2 of the double-sided load-bearing surface 2 of the adjacent two integrated guide rubber teeth and the arc groove 4 of the dedendum 20°, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com