Parameter monitoring system and method for wafer processing capacity per hour of wafer processing furnace

A wafer processing and monitoring system technology, applied in chemical instruments and methods, post-processing, post-processing details, etc., can solve the problem of inability to distinguish between automatic wafer processing and manual operation processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

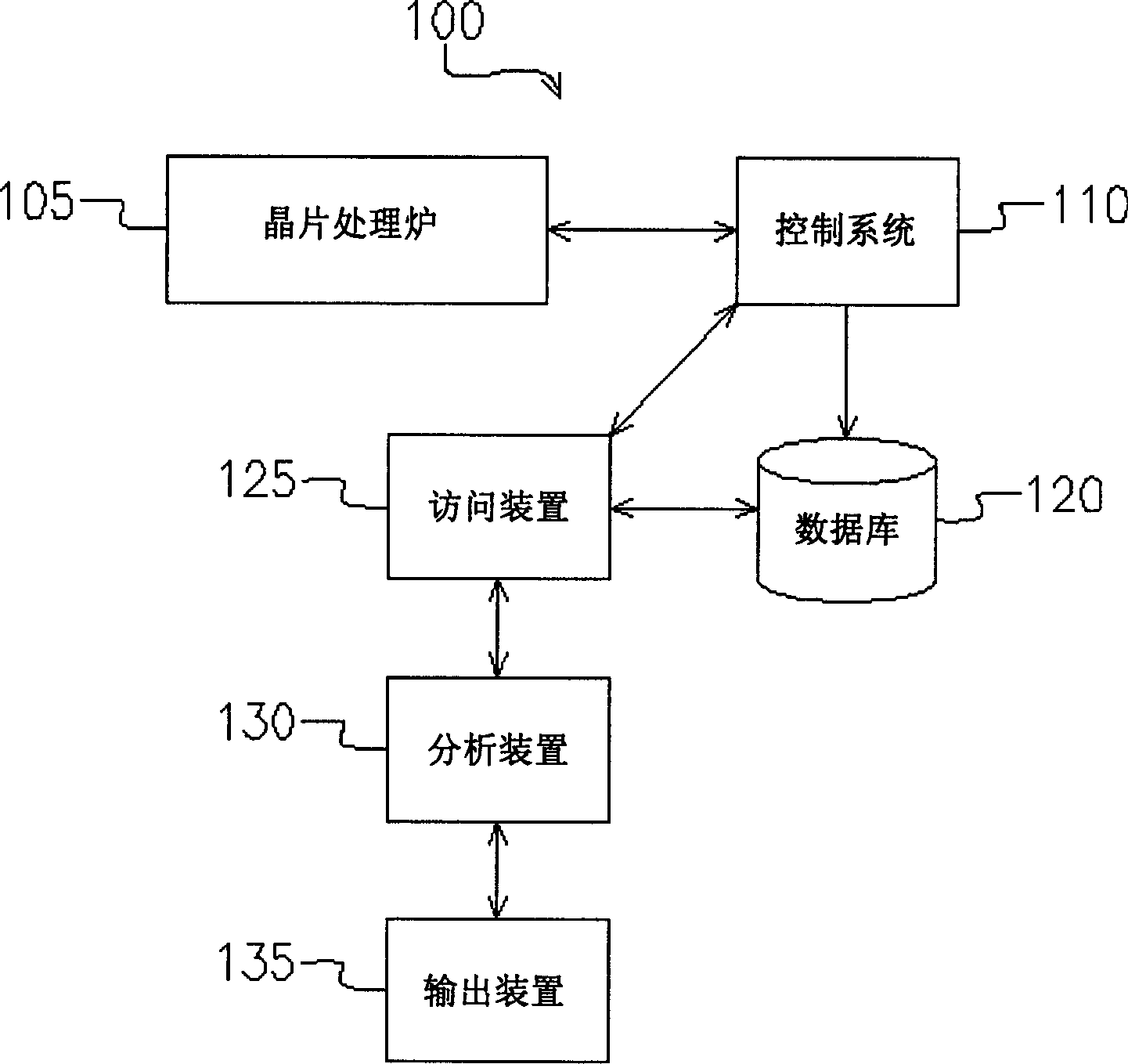

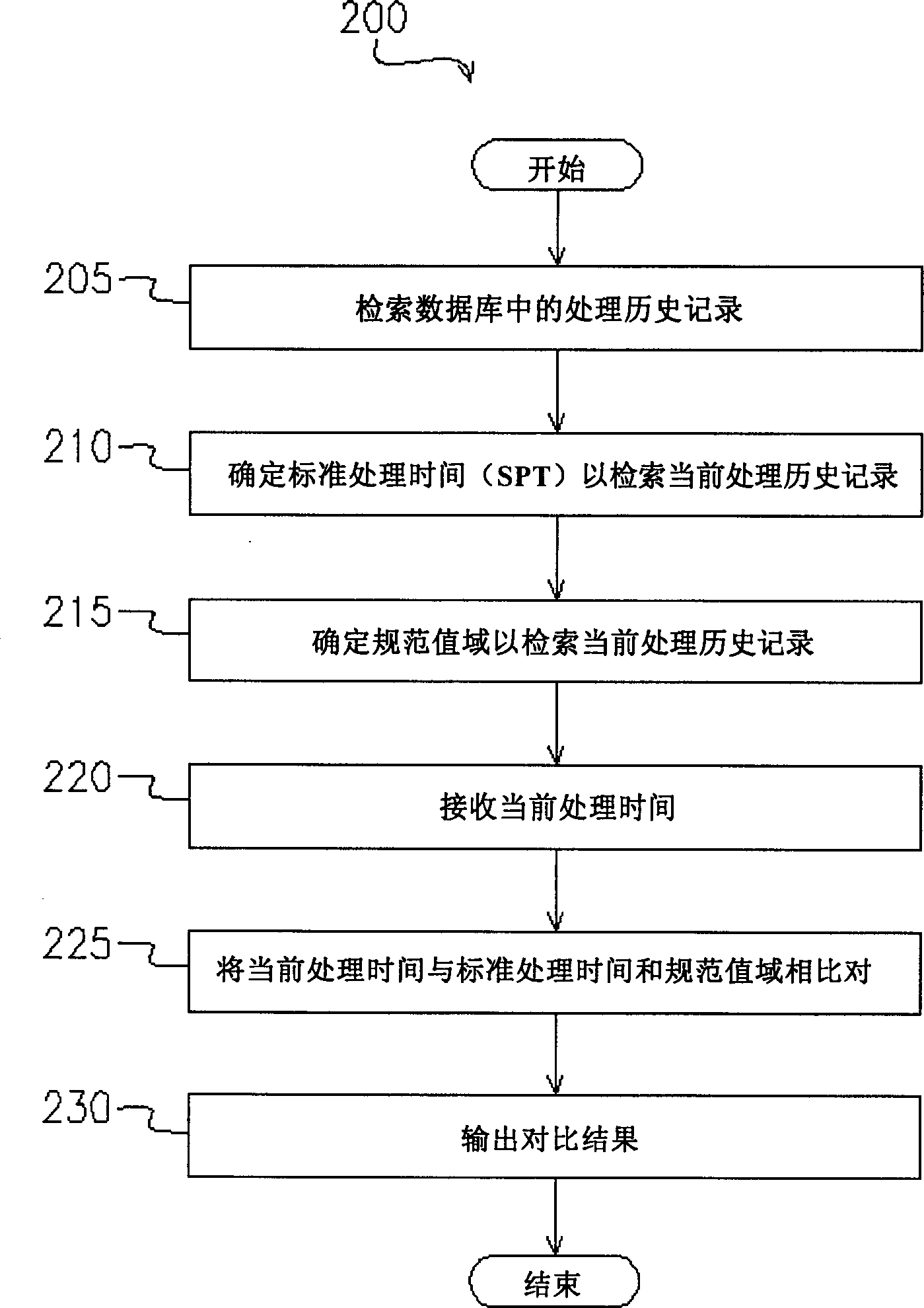

[0023] The wafer processing furnace wafer throughput per hour (WPH) parameter monitoring system and method described below are a few exemplary embodiments. It will be apparent to anyone skilled in the art that the invention may be practiced without some or all of the specific details described below.

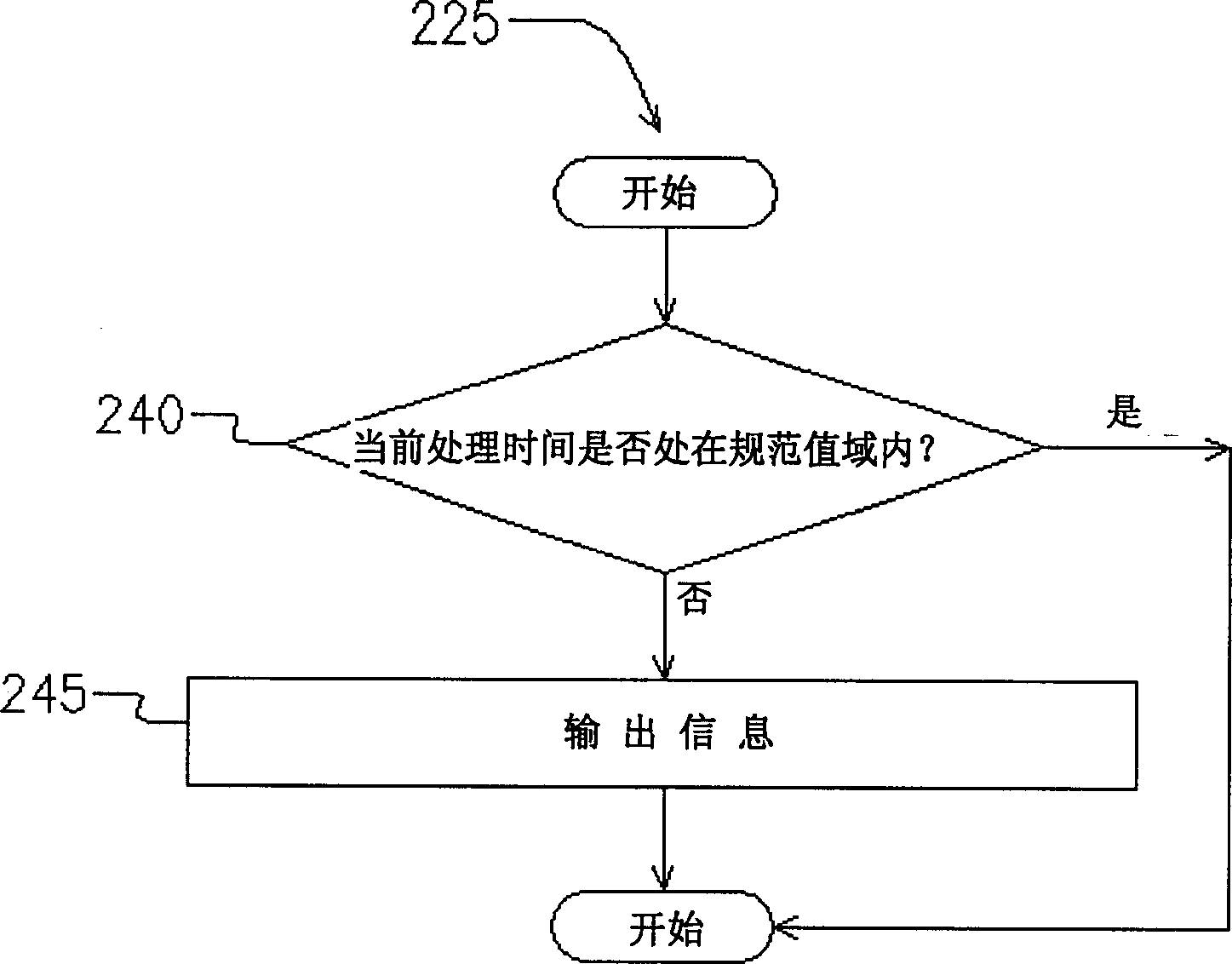

[0024] The wafer throughput per hour (WPH) parameter is an important metric for monitoring wafer processing furnace performance. However, wafer throughput per hour (WPH) parameters must be accurate and provide real useful information. In an embodiment of the invention, the determination of the wafer throughput per hour (WPH) parameter excludes manual wafer handling from automated wafer handling due to the unavoidable inconsistency in results due to operator-to-operator variability Too much sex. Therefore, including manual processing results in inaccurate results for wafer throughput per hour (WPH) parameters. In another embodiment, the present invention notifies an operator o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com