Cavity body structure of microwave oven

A microwave oven and cavity technology, applied in the field of microwave ovens, can solve problems such as difficult maintenance work, and achieve the effects of easy installation of accessories, minimized area, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

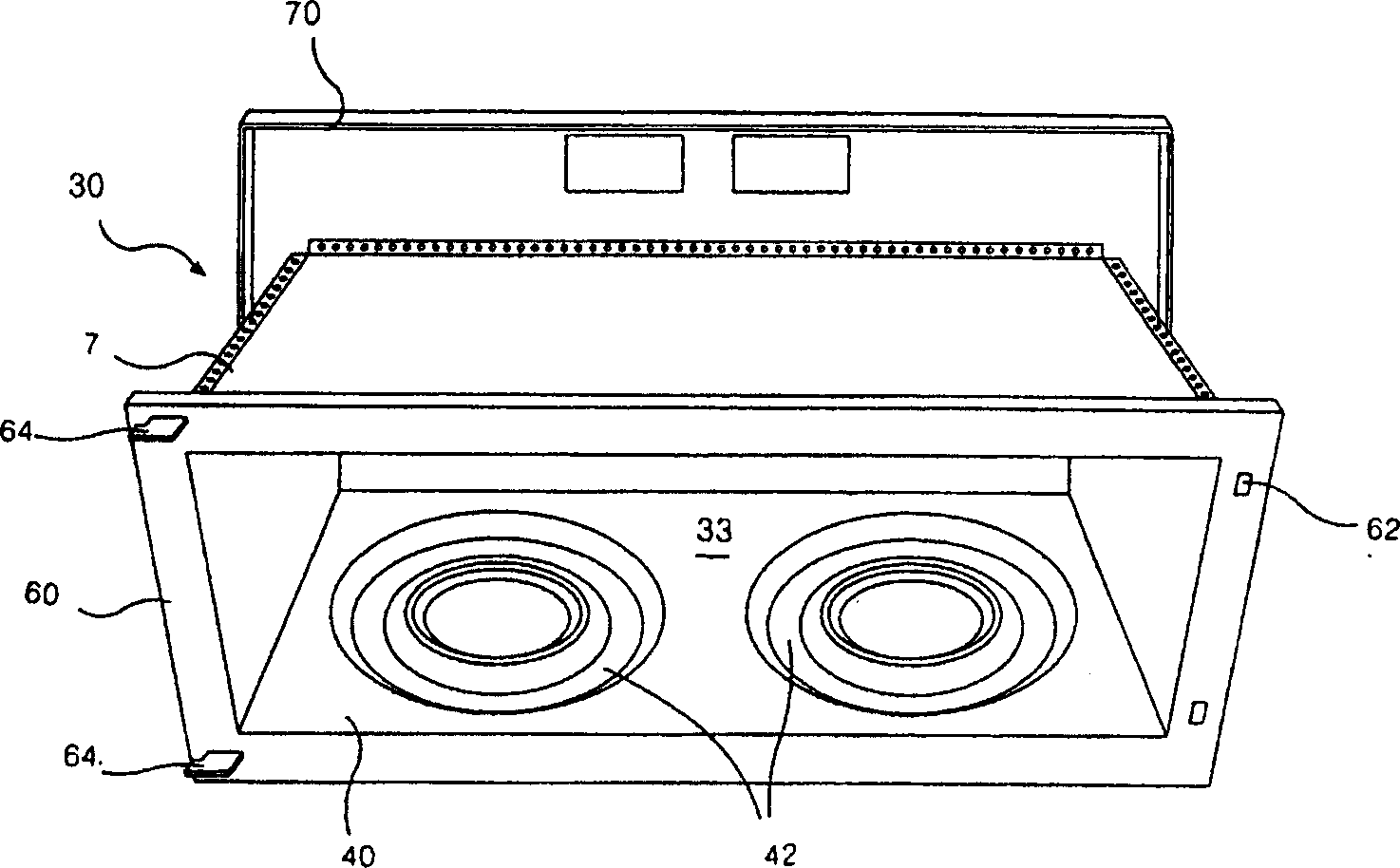

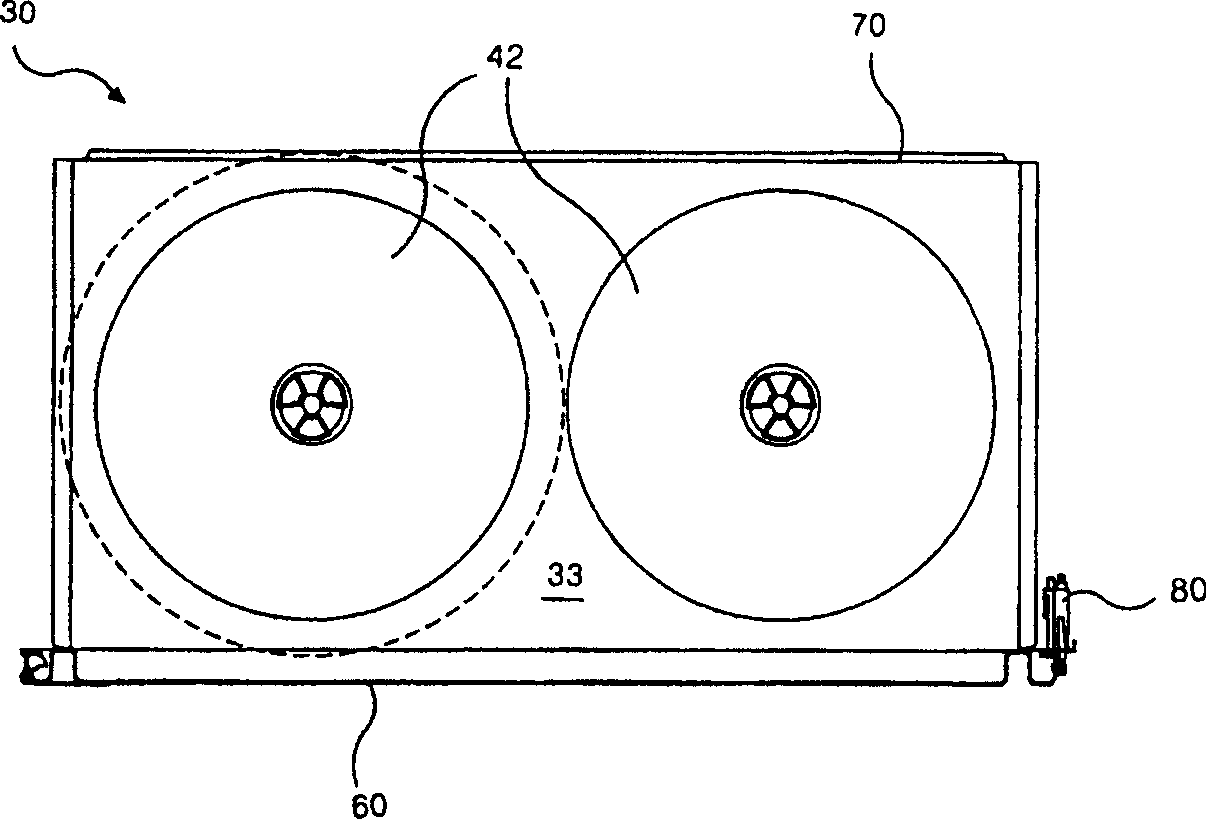

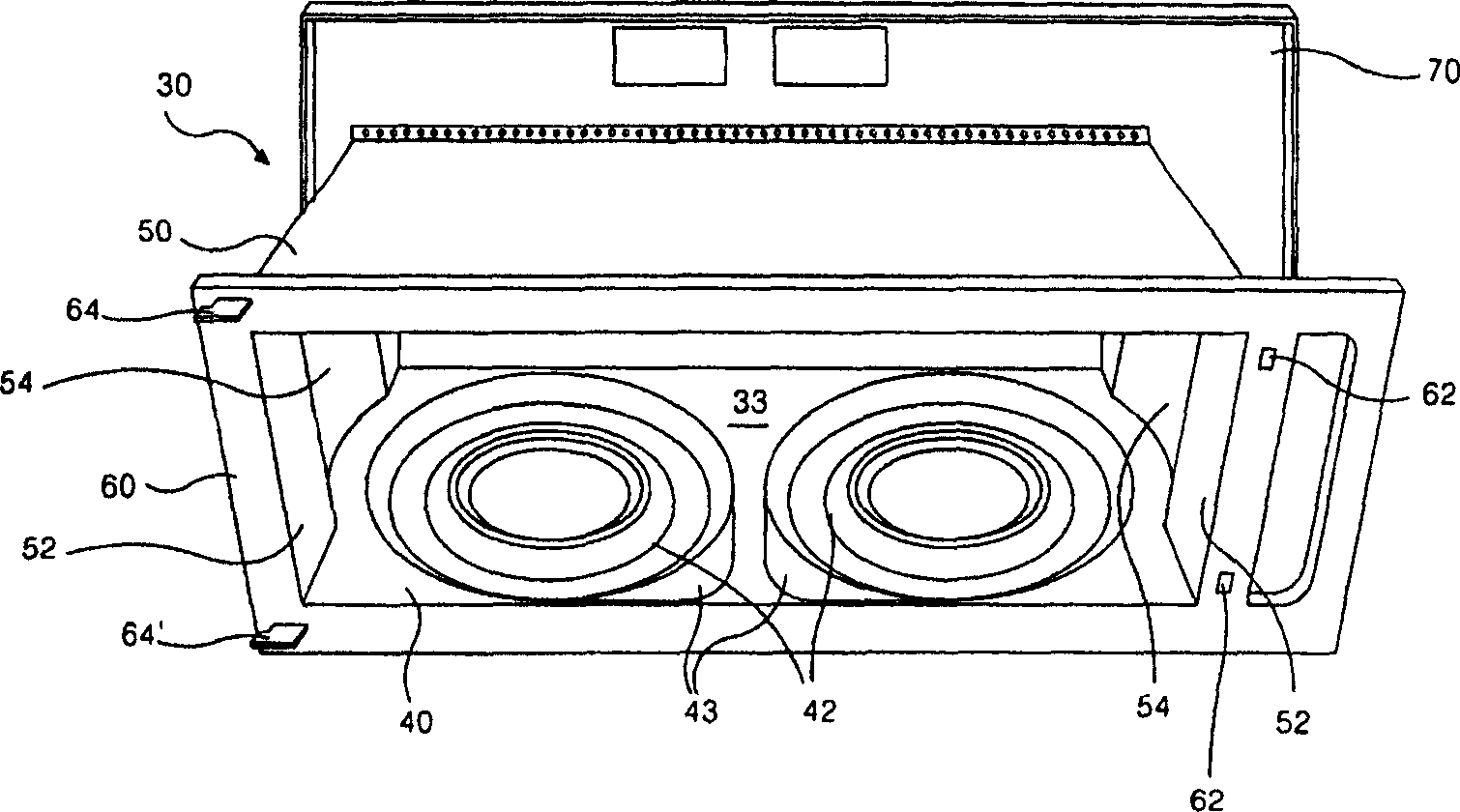

[0033] The cavity structure of the microwave oven of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments: image 3 Represent the stereogram of the cavity of the microwave oven designed by the present invention, Figure 4 Represent the cavity structure plan view in the embodiment of the present invention, Figure 5 It shows a three-dimensional view of the side structure of the cavity in the embodiment of the present invention.

[0034] As can be seen from the figure, in the embodiment of the present invention, the cavity 30 is composed of a lower panel 40 , an upper panel 50 , a front panel 60 and a back panel 70 , and a cooking chamber 33 is formed inside it.

[0035] Firstly, the lower panel 40 forms the bottom of the cavity 30 . On such a lower panel 40, a tray bracket 42 is formed, and the tray bracket 42 forms a circle in order to rotate the tray when food is placed on the tray (not shown). Mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com