Pattern

A surface pattern and mosaic technology, applied in the field of surface patterns, can solve the problem of converting unpredetermined patterns into diffraction structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

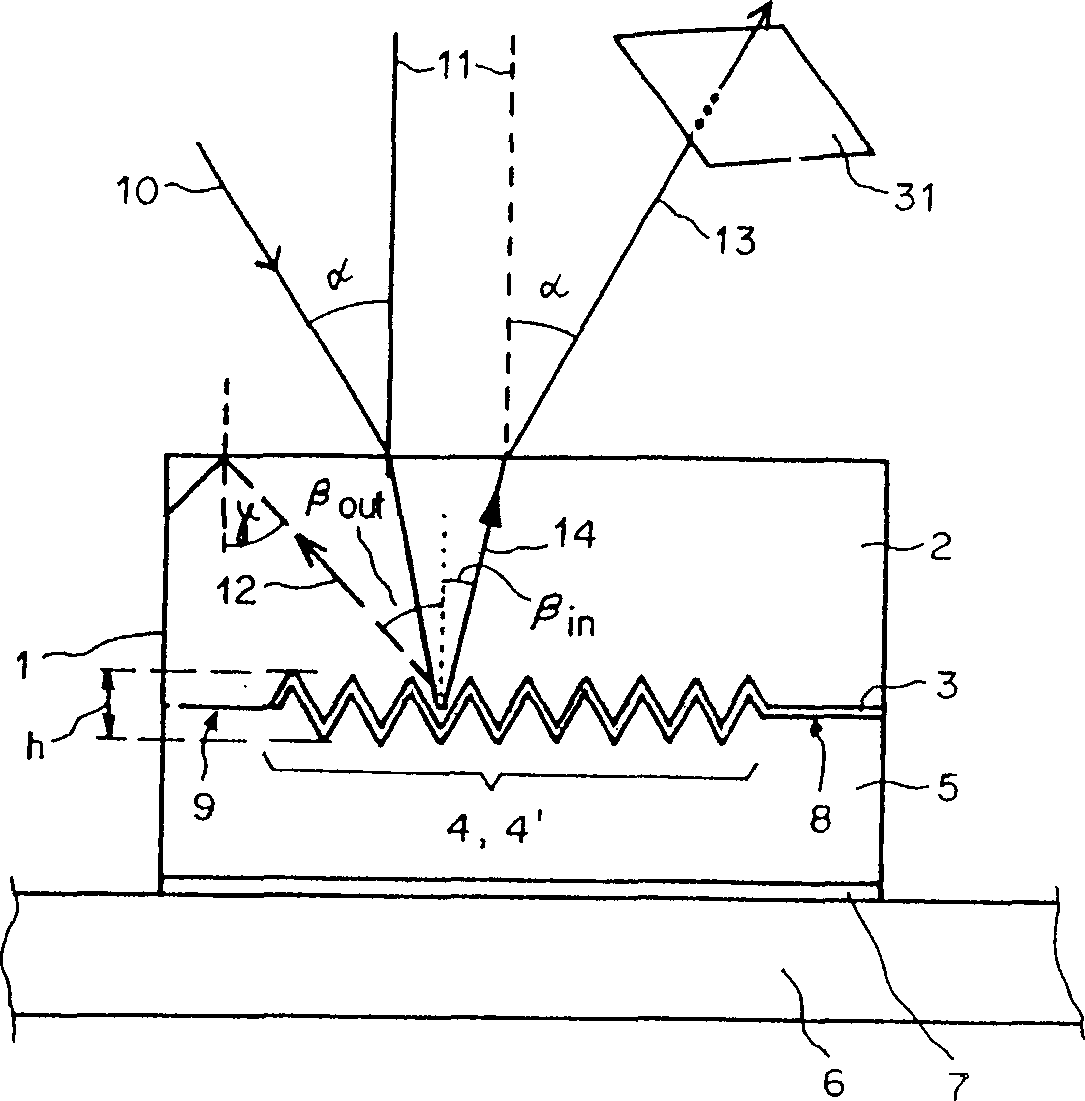

[0023] figure 1 In, reference numeral 1 denotes a laminate, 2 denotes a transparent covering layer made of polymer, 3 denotes a reflective layer, 4 denotes a microscopic concave-convex structure, 5 denotes a protective layer made of polymer, and 6 denotes a substrate. The protective layer 5 away from the reflective layer 3 is either covered by the adhesive layer 7, or the protective layer 5 itself has an adhesive function. Suitable for bonding are cold bonding or hot melt bonding, the choice of bonding depends on how it will be used. Form microscopic concave-convex structure 4 in cover layer 2, and cover with reflective layer 3, reflective layer 3 also covers the surface part 8 and 9 that do not have structure at the same time, wherein, surface part 8 and reflective layer 3 serve as specular reflective surface 8 together, Alternatively, the surface portion 9 is provided without the reflective layer 3 as a transparent window 9 . The protective layer 5 is either visible throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com