Secondary battery

A technology of secondary battery and collector plate, applied in the direction of secondary battery, secondary battery manufacturing, battery pack components, etc., to achieve the effect of high current collection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

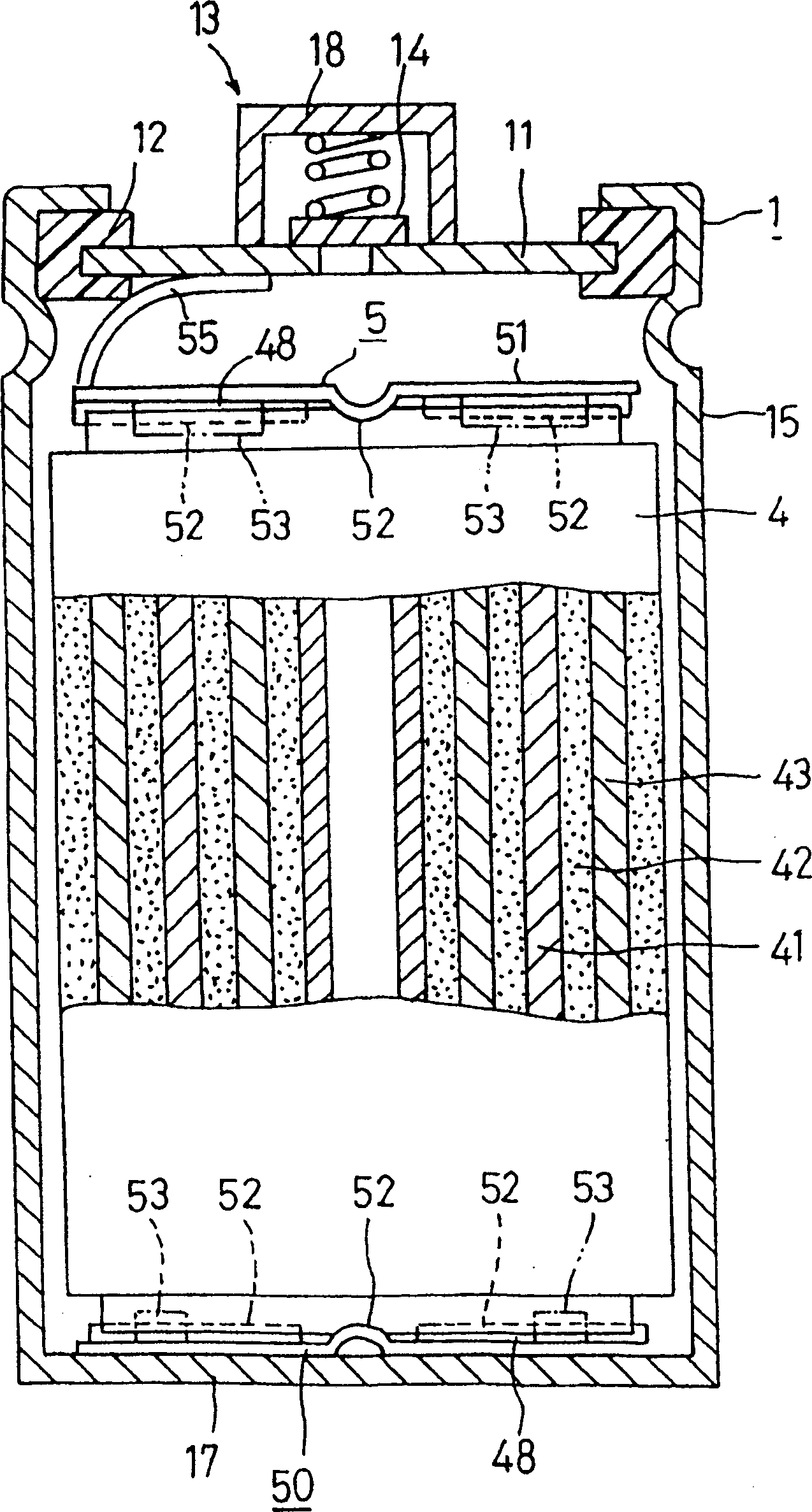

[0034] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings. Such as figure 1 As shown, the secondary battery of the present invention is constituted by installing a wound electrode body (4) inside a cylindrical battery can (1) whose surface is nickel-plated on a steel base material. The battery can (1) utilizes an insulating member (12) to fix the lid (11) on the opening of the bottomed cylinder (15), forming an outer diameter of 30 mm and a length of 65 mm. A positive terminal (18) incorporating a safety valve (14) is attached to the lid (11) of the battery can (1), and the positive terminal (18) constitutes a positive terminal portion (13). In addition, the negative electrode terminal portion (17) is constituted by the bottom of the bottomed cylindrical body (15).

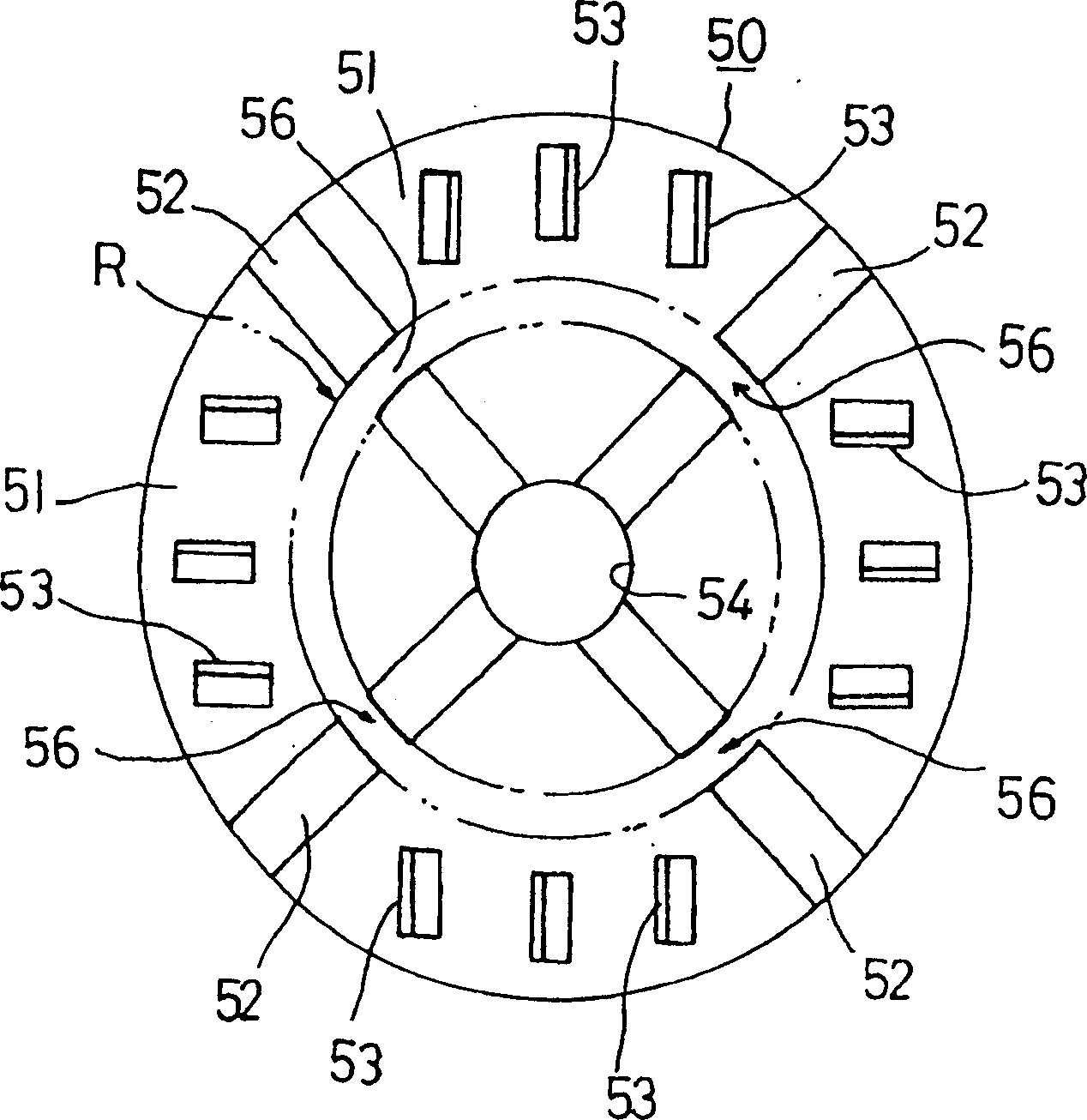

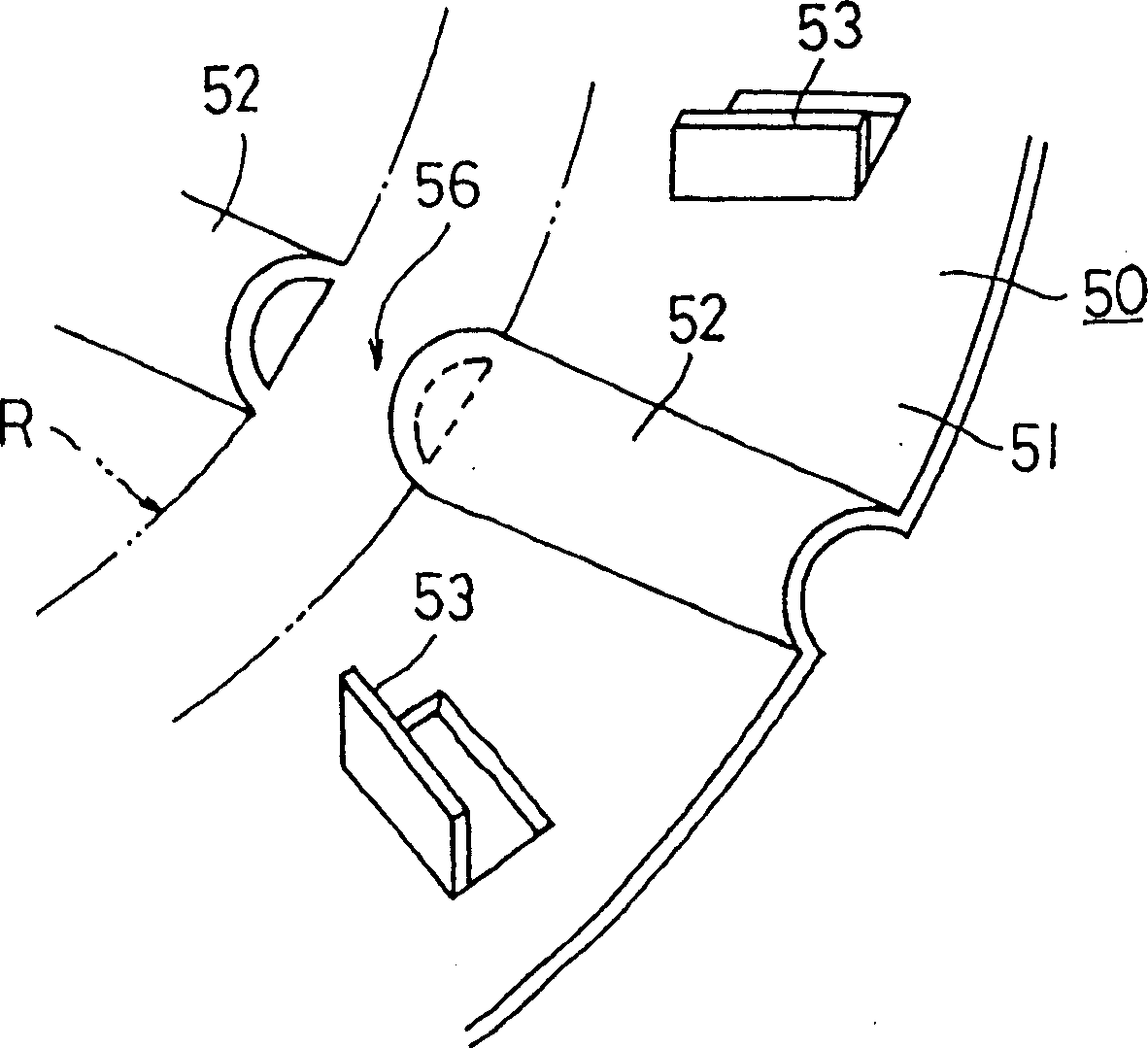

[0035] Such as Image 6 As shown, the wound electrode body (4) is formed by interposing a belt-shaped separator (42) between each belt-shaped positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com