A microbial fuel cell coupled composite flow constructed wetland system for wastewater treatment

A constructed wetland system and fuel cell technology, applied in biochemical fuel cells, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as high COD concentration, surface water pollution, and difficult treatment, and achieve Solve water pollution, achieve no carbon emissions, and improve the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

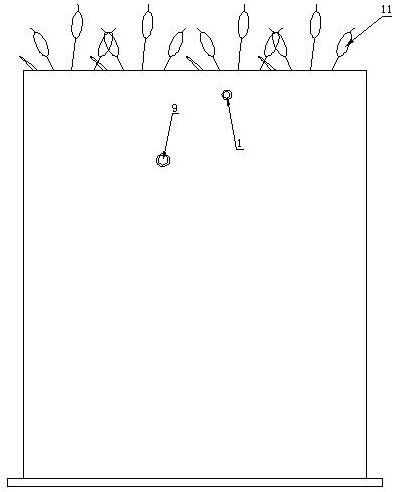

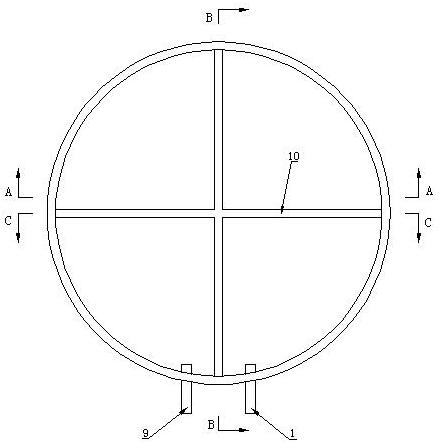

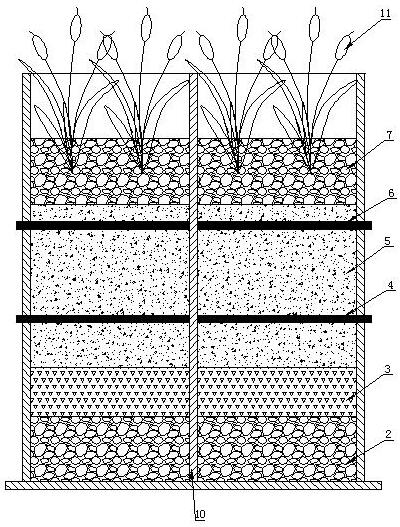

[0045] Such as Figure 1~6 As shown, a microbial fuel cell coupling composite flow constructed wetland system (MFC-CFCW system) for wastewater treatment includes a cylindrical pool body, and four partitions 10 are arranged in the pool body, and the partition boards 10 divide the pool The body is divided into 4 series units. The upper part of the side wall of one of the series units is provided with a water inlet, and the water inlet is connected with a water inlet pipe 1, and the upper part of the side wall of one of the series units is provided with a water outlet, and the water outlet is connected with a water outlet pipe 9; the height of the water outlet The height of the water inlet is lower than that of the water inlet, thereby forming a water level difference, which is conducive to the continuous and uniform flow of water. The waste water flows from the water inlet to the water outlet, and flows through all series units in a counterclockwise direction; along the directio...

Embodiment 2

[0063] Keep the structure of the MFC-CFCW system described in Example 1 unchanged, and only change the anode plate 4, cathode plate 6, biocompatible filler, conductive filler and wetland plants.

[0064] Described anode plate 4 and cathode plate 6 all adopt following steps to make:

[0065] (1) Soak the mature and sun-dried octagonal melon fruit in 20% NaOH solution for 30 h to remove the ash, then wash it with water until it is neutral and dry it, put it in a tubular electric resistance furnace, and heat it in a nitrogen atmosphere. carbonization at 200°C for 3 h; the flow rate of nitrogen into the tubular resistance furnace was 0.4 L / min, and the heating rate of the resistance furnace was 8°C / min;

[0066] (2) Soak the product obtained in step (1) in dilute hydrochloric acid with a mass fraction of 5% for 6 h, then separate the solid from the liquid, dry the solid, and grind it into powder to obtain the main ingredient powder;

[0067] (3) Mix the main ingredient powder, ca...

Embodiment 3

[0077] Keep the structure of the MFC-CFCW system described in Example 1 unchanged, and only change the anode plate 4, cathode plate 6, biocompatible filler, conductive filler and wetland plants.

[0078] Described anode plate 4 and cathode plate 6 all adopt following steps to make:

[0079] (1) Soak the ripe and sun-dried octagonal melon fruit in 30% NaOH solution for 20 h to remove the ash, then wash it with water until neutral and dry it, put it in a tubular electric resistance furnace, and heat it in a nitrogen atmosphere carbonization at 500°C for 2 h; the flow rate of nitrogen into the tubular resistance furnace was 0.6 L / min, and the heating rate of the resistance furnace was 10°C / min;

[0080] (2) Soak the product obtained in step (1) in dilute hydrochloric acid with a mass fraction of 15% for 4 h, then separate the solid from the liquid, dry the solid, and grind it into powder to obtain the main ingredient powder;

[0081] (3) Mix the main ingredient powder, carbon bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com