Grid, pole plate and pole plate group used for lead storage battery, and lead storage battery

A technology of lead-acid batteries and plate groups, which is applied in the fields of grids, plates, plate groups and lead-acid batteries for lead-acid batteries. Current collection and the effect of reducing the possibility of internal short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Manufacturing of positive plate

[0051] The raw material lead powder (a mixture of lead and lead oxide), water, and dilute sulfuric acid were kneaded in a weight ratio of about 100:12:14 to obtain a positive electrode paste as a positive electrode active material.

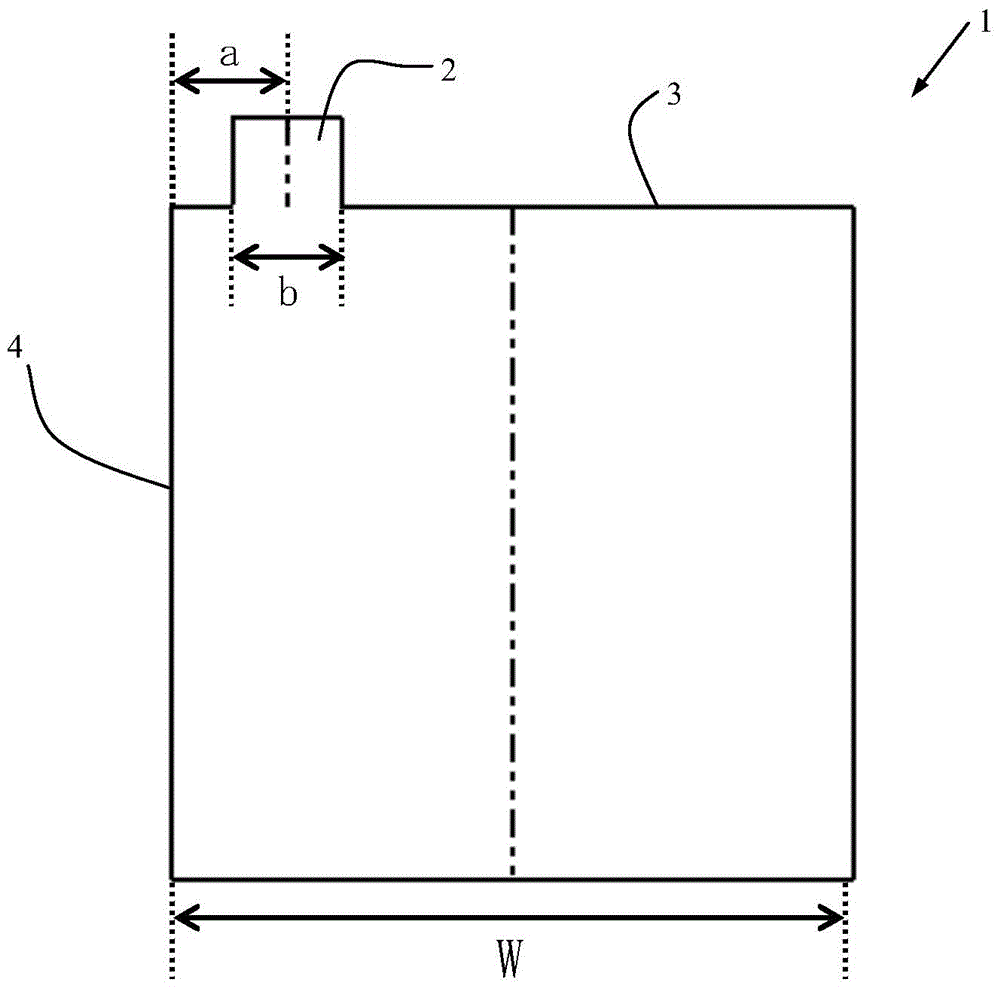

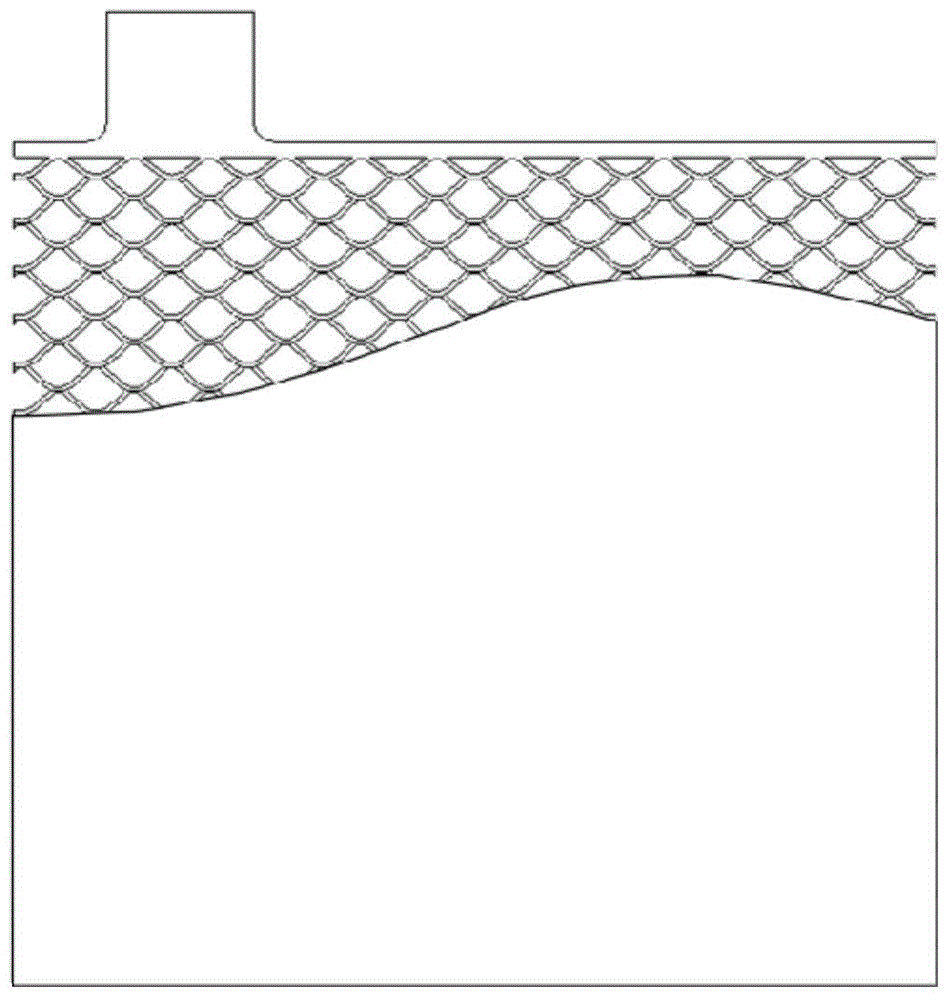

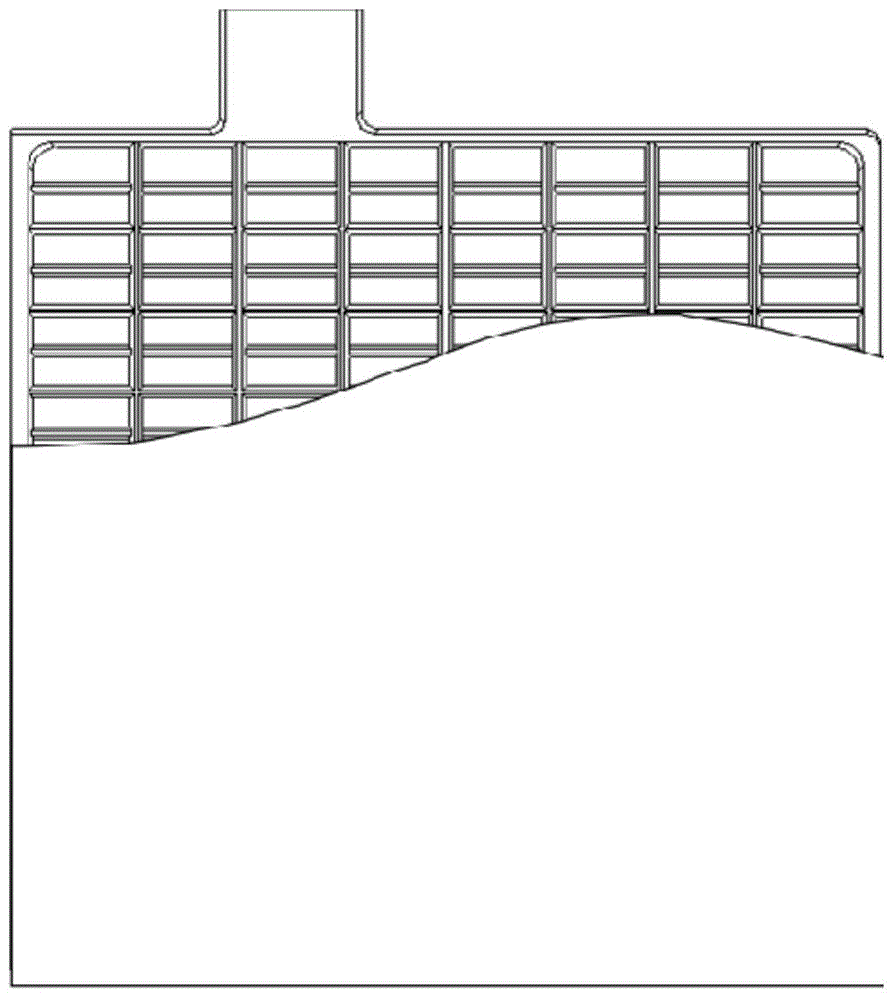

[0052] A 1.3 mm thick lead strip containing a Pb alloy containing about 0.07% by mass of Ca and about 1.3% by mass of Sn is repeatedly punched and unfolded using a reciprocating punching die through a cutting and drawing process, thereby forming a structure with a staggered structure of multiple grid lines Mesh of the grid. Then, the mesh sheet is shaped using a pair of rollers of a shaping mold to obtain a positive electrode plate drawn mesh grid as a positive electrode current collector. Then, the positive electrode paste is filled into the grid along the longitudinal direction of the grid on the expanded grid to form a lead plate. Then, the lead plate is cut into a positive electrode plate with a positi...

Embodiment 2~5

[0089] Except that the ratio a / W of the positive plate was 0.31 to 0.34, the plate group and the lead storage battery were prepared according to the same setup and process as in Example 1.

Embodiment 6~9

[0095] Except that the ratio b / W of the positive electrode plate was 0.14 to 0.205, the electrode plate group and the lead storage battery were prepared according to the same setup and process as in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com