Electrode active material covered with carbonaceous material, electrode for secondary battery, and secondary battery

An electrode active material, carbonaceous material technology, applied in non-aqueous electrolyte battery electrodes, battery electrodes, circuits, etc., can solve the problems of unresearched carbon black structure, unresearched carbonaceous materials, etc., to improve the current collection effect, improve Effect of battery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

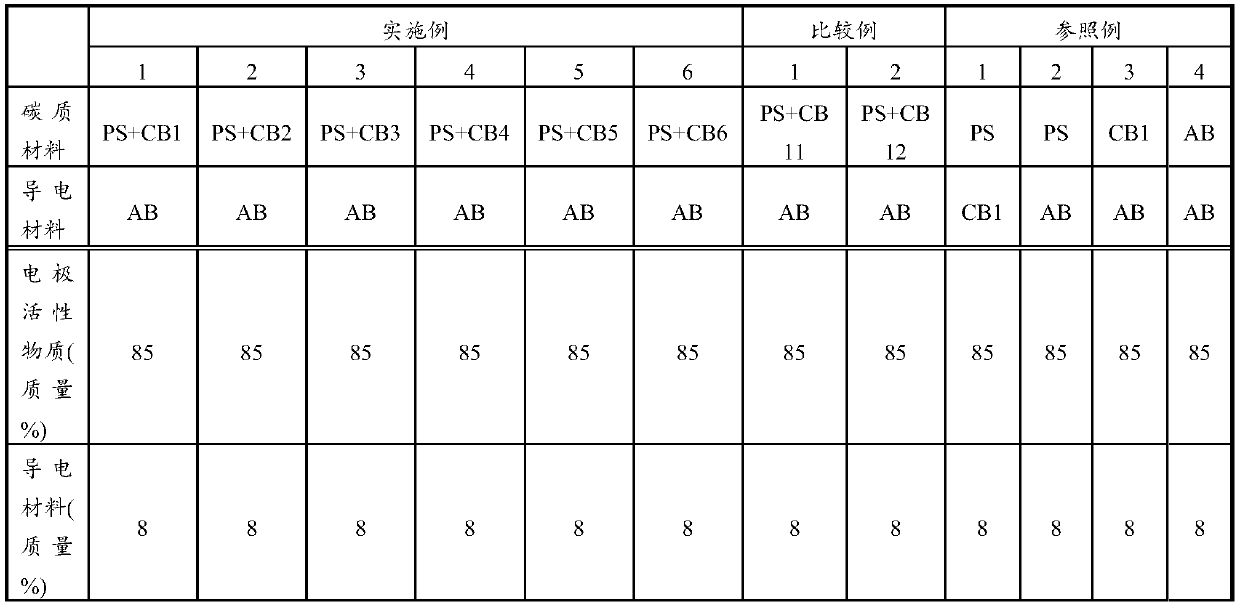

Embodiment 1~6、 comparative example 1~2

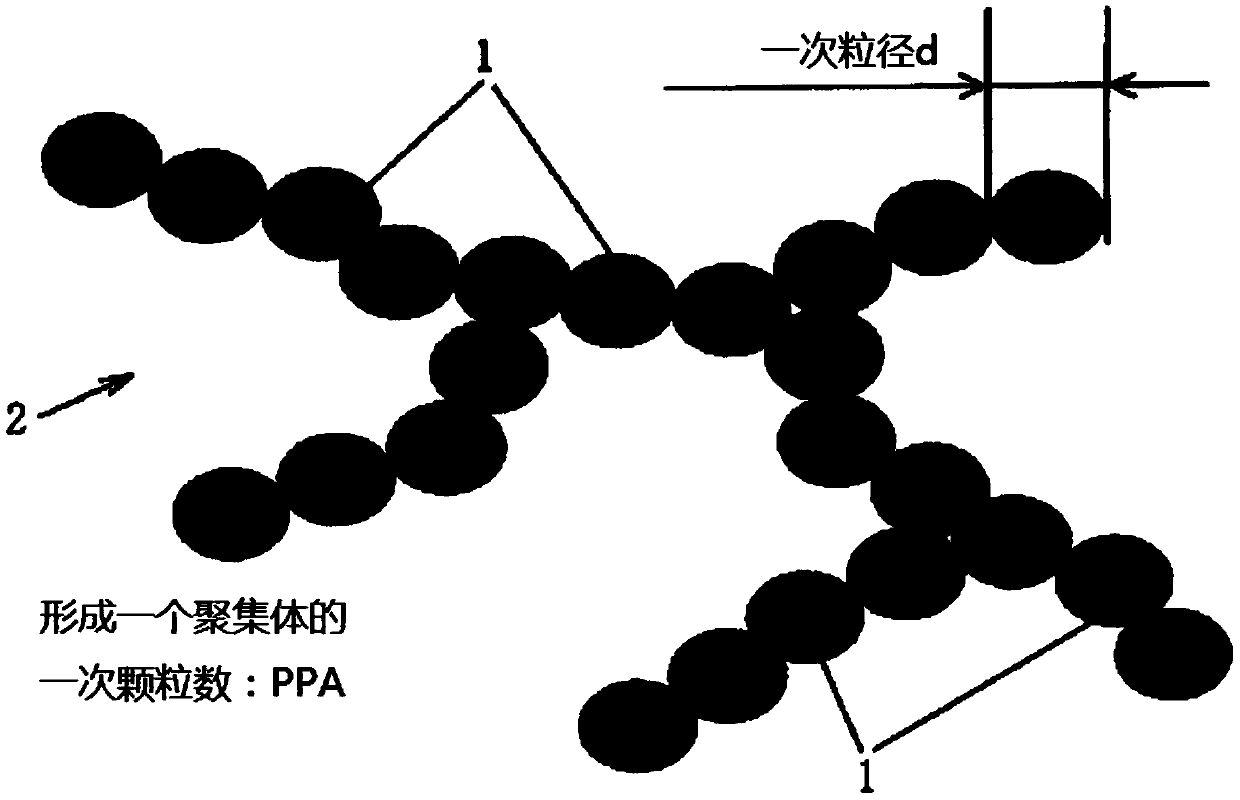

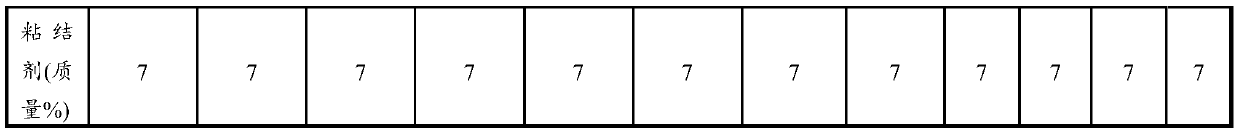

[0049] Using carbon black and / or polystyrene (PS: MW=2000, Wako Pure Chemical Industries, Ltd.) produced under the conditions shown in Table 1 and having the properties shown in Table 2, a carbonaceous material-covered electrode active material. Electrodes were fabricated using these electrode active materials, and these electrodes were used as positive electrodes to fabricate secondary batteries. The production sequence is described below. Table 3 shows the types of carbonaceous materials and conductive materials used, and the ratios (% by mass) of conductive materials, electrode active materials, and binders.

[0050] (Production of carbon-coated LFP (electrode active material))

[0051] LFP (LiFePO 4 ) was pre-calcined at 320°C for 5 hours in an environment of argon:hydrogen=95:5, and then dry-mixed with carbon black using a ball mill. Next, polystyrene and xylene as an organic solvent were further added and wet-mixed with a ball mill, and then xylene was evaporated. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com