Linear cutting discharging processing device and its control method

A control method and electric discharge machining technology, applied in electric machining equipment, program control, general control system, etc., can solve the problems of wire electrode breakage and disadvantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

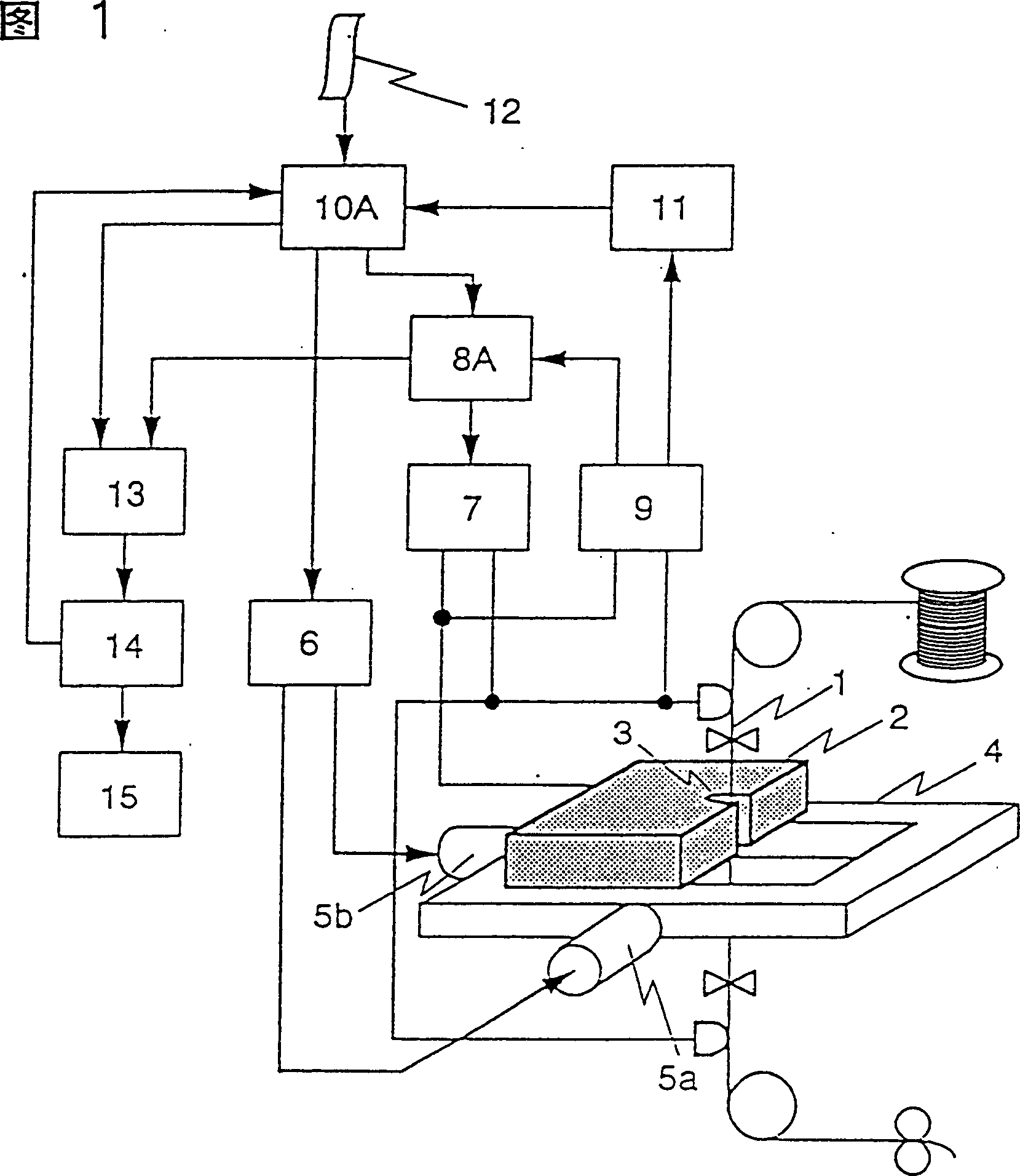

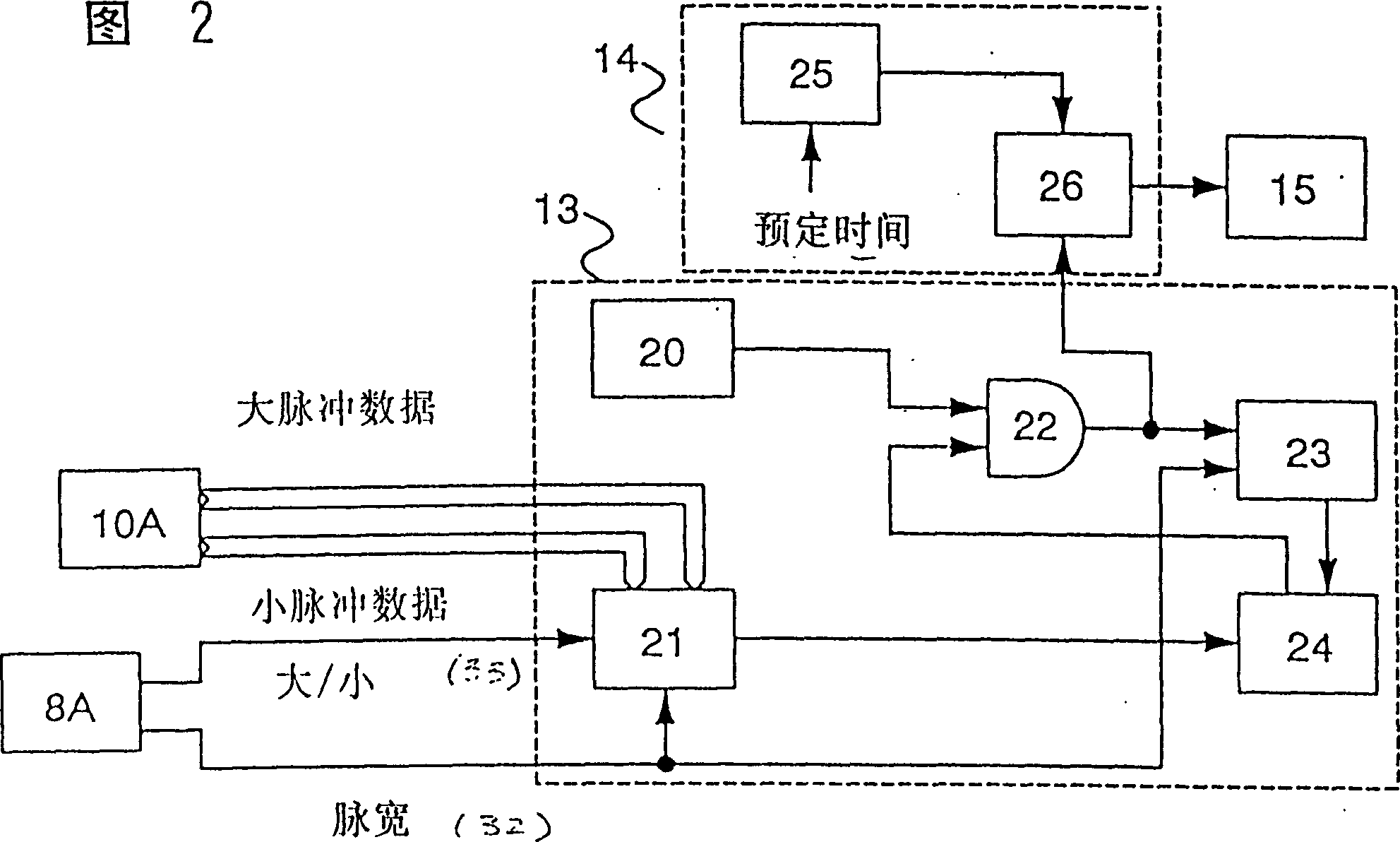

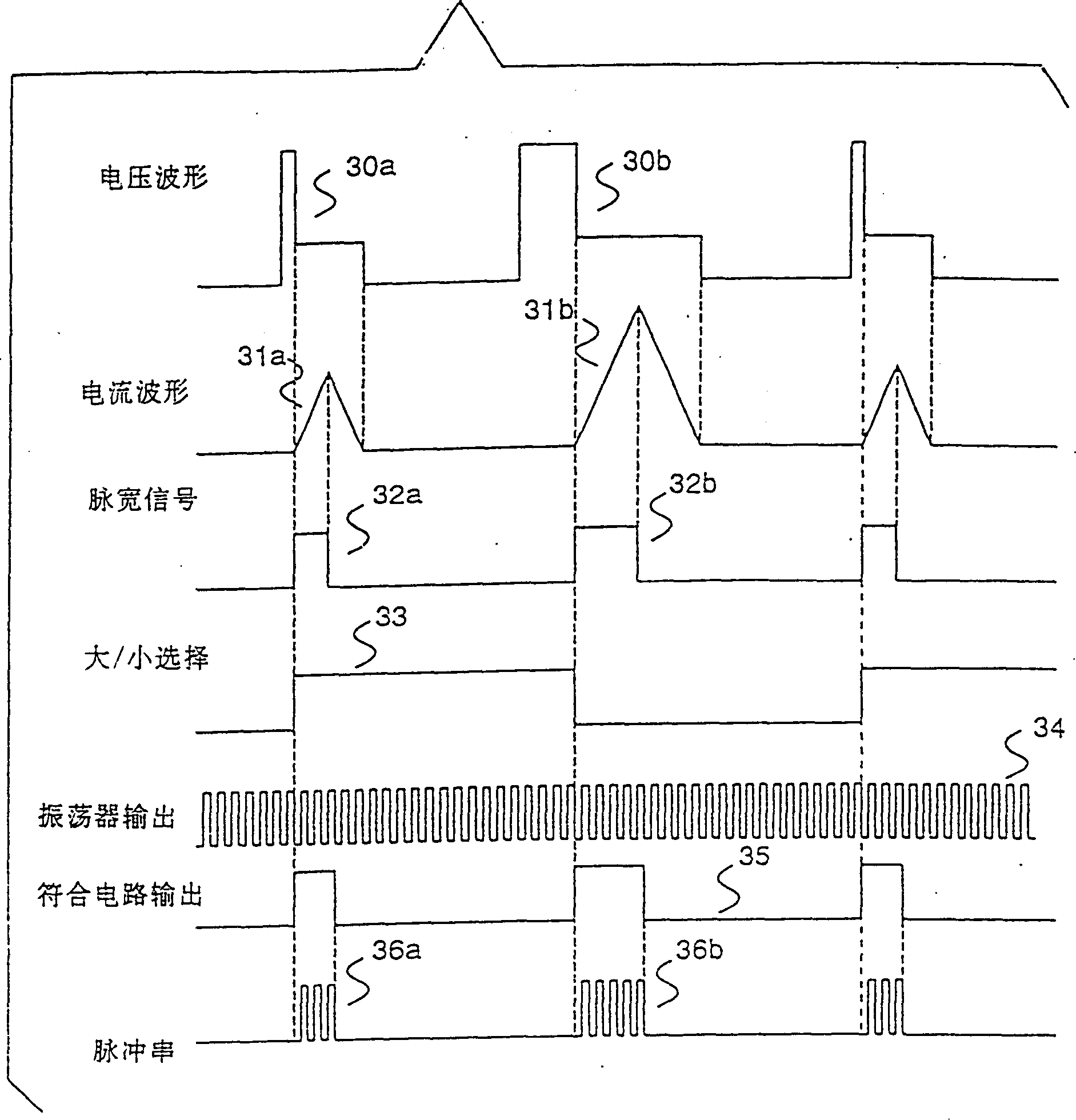

[0051] Referring to Figure 1 to Figure 5 A first embodiment of the present invention is described.

[0052] FIG. 1 depicts a wire-cut electric discharge machining device of the first embodiment. In the figure, 1 represents a linear electrode; 2 represents a workpiece; 3 represents the processing gap formed by the linear electrode 1 and the workpiece 2; 4 represents a worktable for fixing the workpiece 2; 5a represents a drive table 4 along the X-axis direction 5b represents a Y-axis drive motor that drives the workbench 4 along the Y-axis direction; 6 represents a shaft drive control device that controls the X-axis and Y-axis drive motors 5a, 5b; 7 represents that the machining gap 3 provides The processing power supply of the discharge current pulse; 8A represents a processing power supply control circuit that controls the switching operation of the processing power supply 7; 9 represents the voltage detection circuit of the processing voltage detected at the processing gap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com