Fully-mechanized mining working plane supplementary laneway multiple passage quick-speed moving process

A technology of fully mechanized mining face and mining face, applied in tunnels, mining equipment, earthwork drilling and other directions, can solve the problems of difficult safety management, many work links, difficult and fast installation, etc., to achieve a good working environment and improve load bearing. Condition, easy-to-manage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

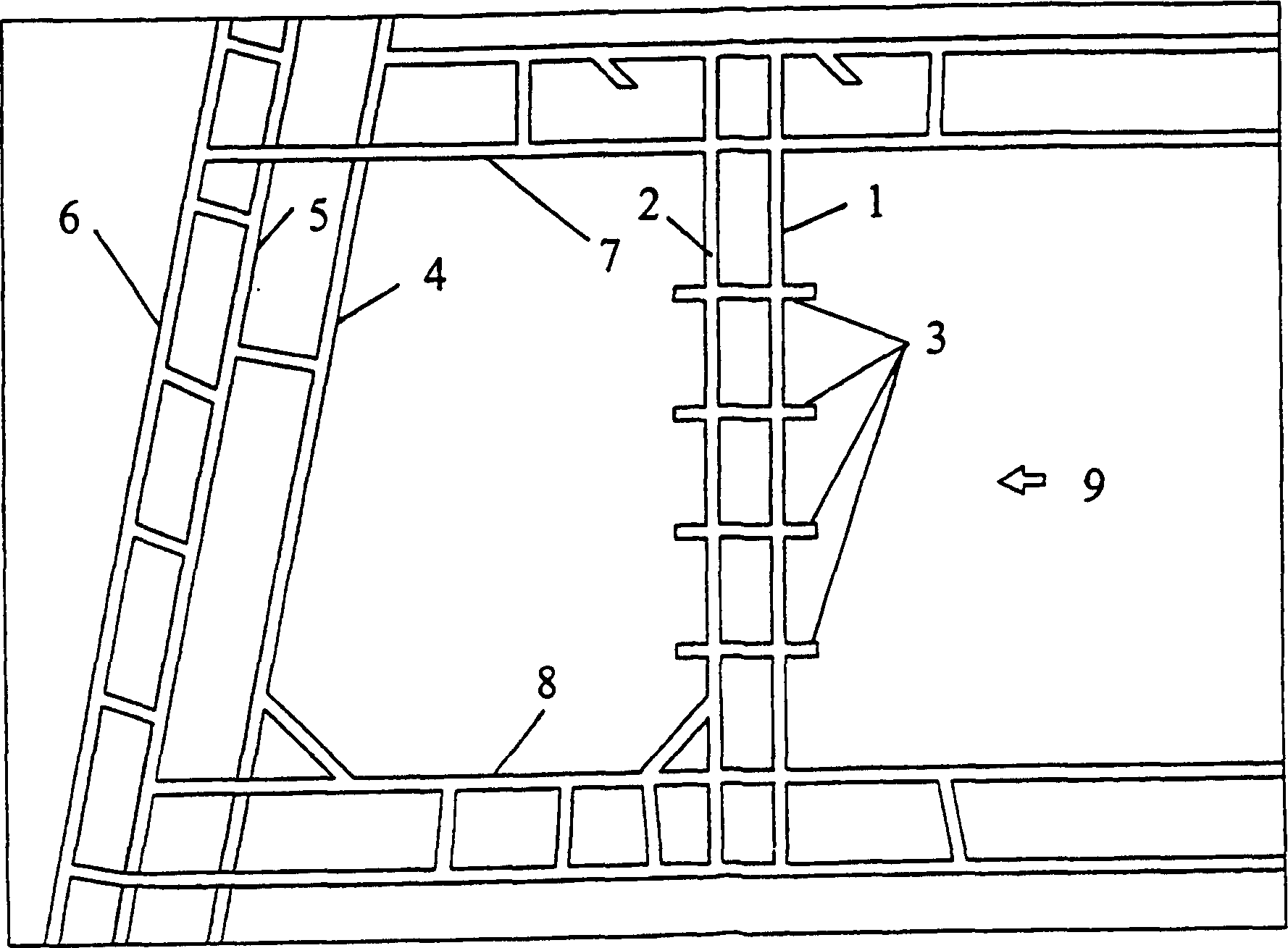

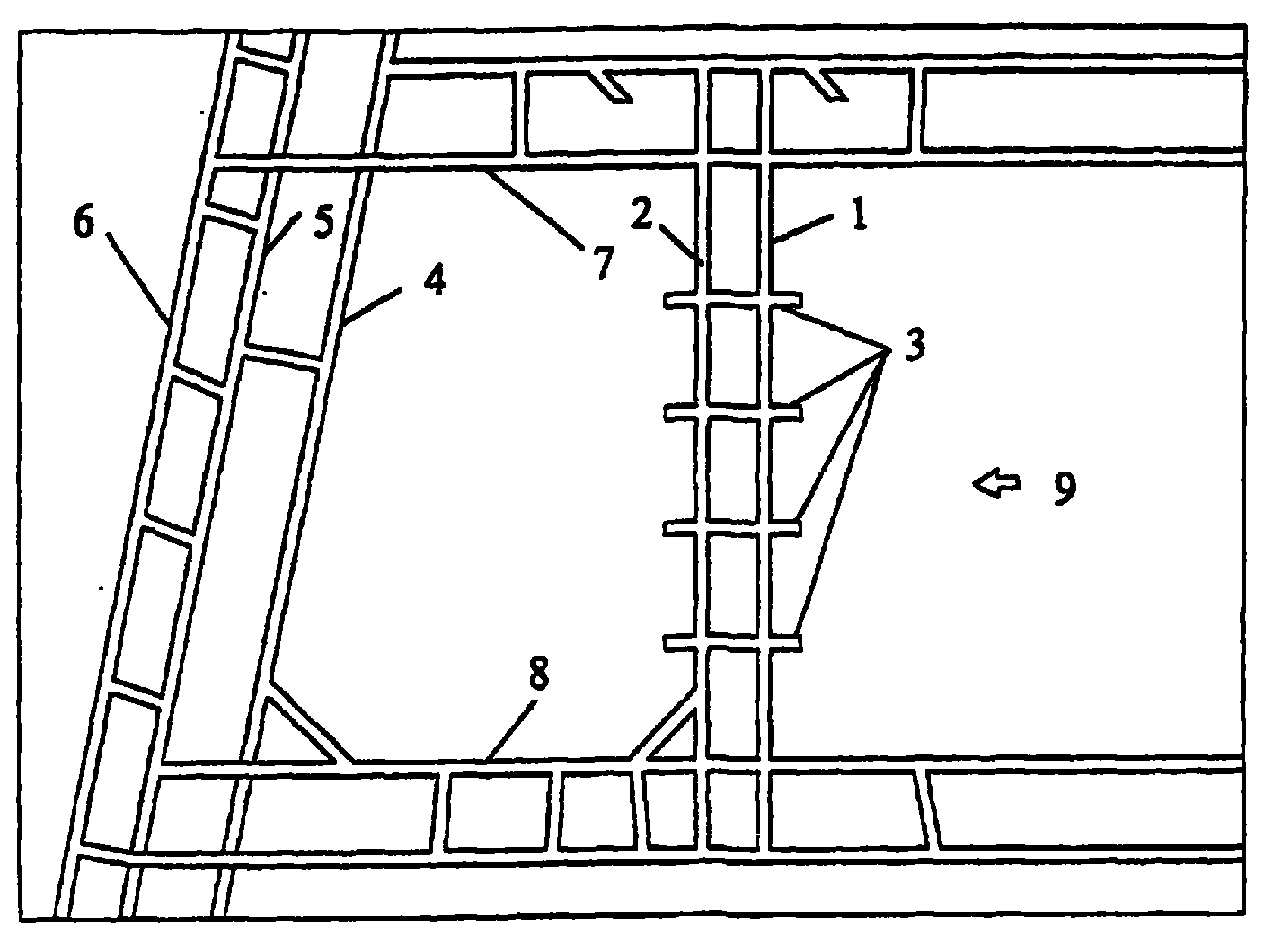

[0023] exist figure 1 Among them, the reference numeral 9 indicates the fully mechanized mining face, and the reference numerals 4, 5, and 6 respectively indicate the substantially parallel return air alleys, rubber transportation alleys and auxiliary transportation alleys. The return air chute 7 and the transport chute 8 are basically perpendicular to the return air alley 4 , the rubber transportation alley 5 and the auxiliary transportation alley 6 .

[0024] According to the present invention, two auxiliary roadways 1 and 2 parallel to the mining face are excavated in advance on the stop production line of the mining face, and then according to the geological conditions of the coal seam, the technical equipment for moving, and the staffing, etc., between the two auxiliary roadways During this period, a number of connecting lanes 3 are excavated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com