Layer combustion method for coal water slurry and equipment therefor

A technology of coal-water slurry and combustion method, which is applied in the field of fuel combustion, can solve problems such as reducing the initial concentration of smoke and dust, and achieve the effects of low labor intensity of workers, large load adjustment range and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

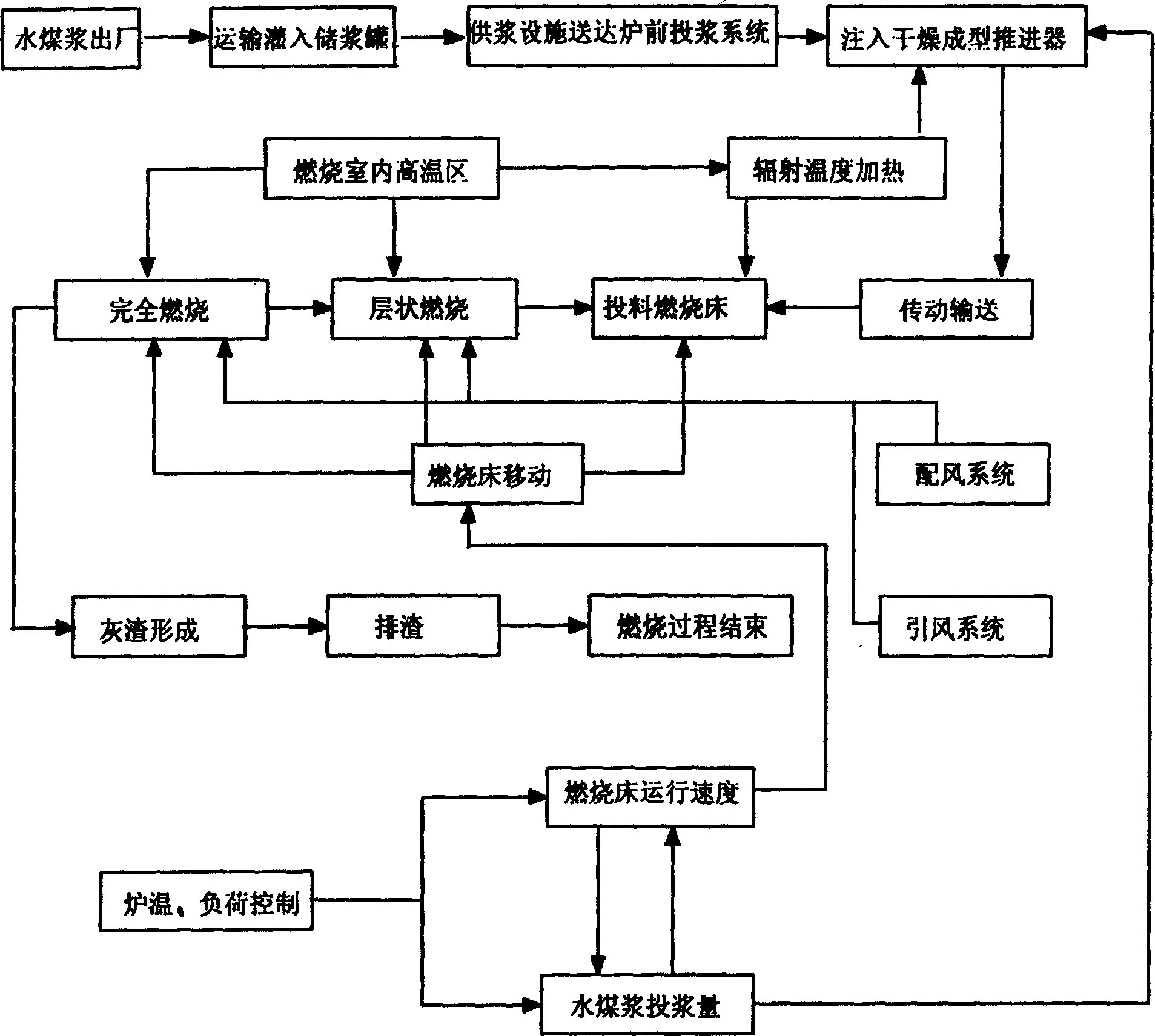

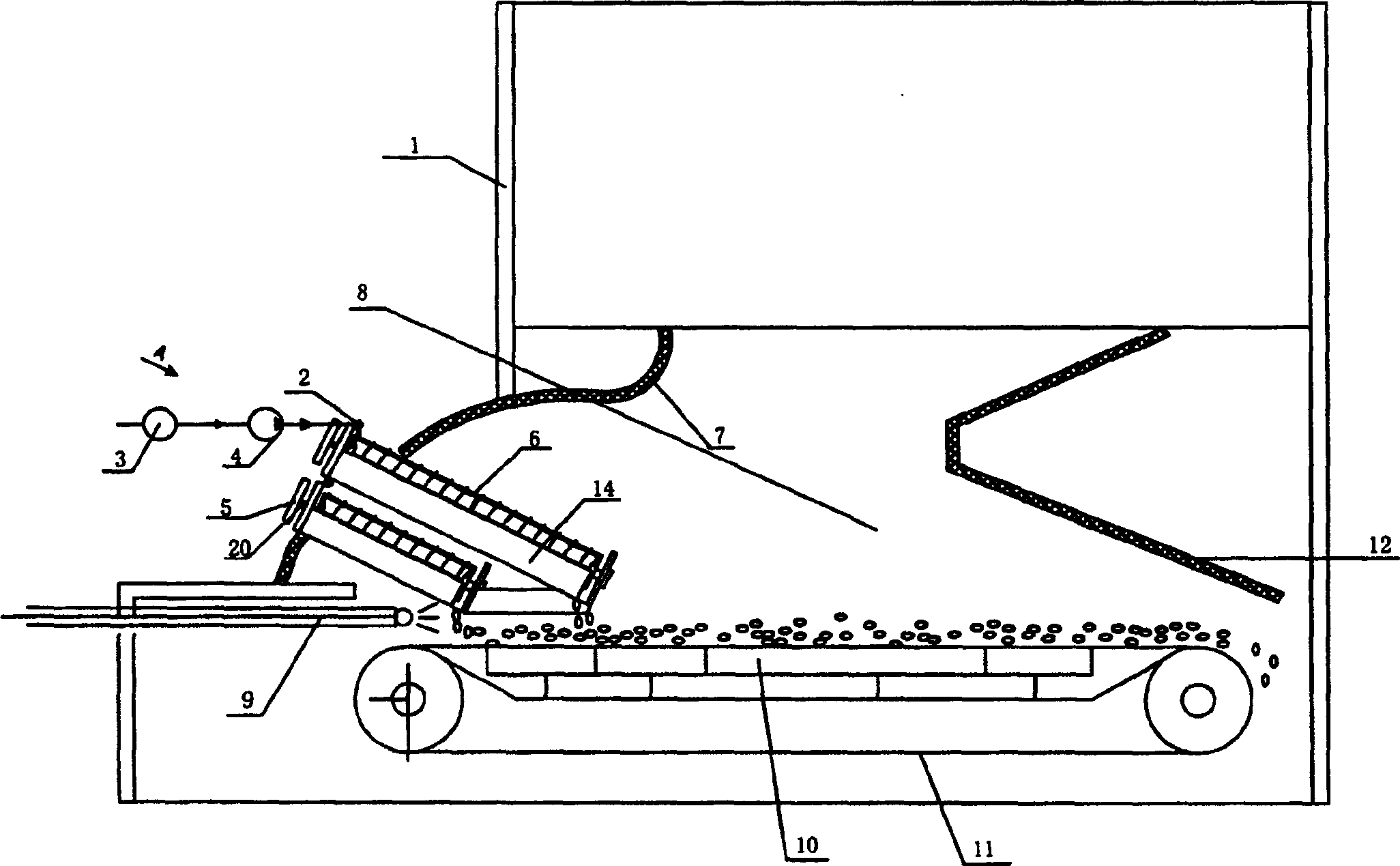

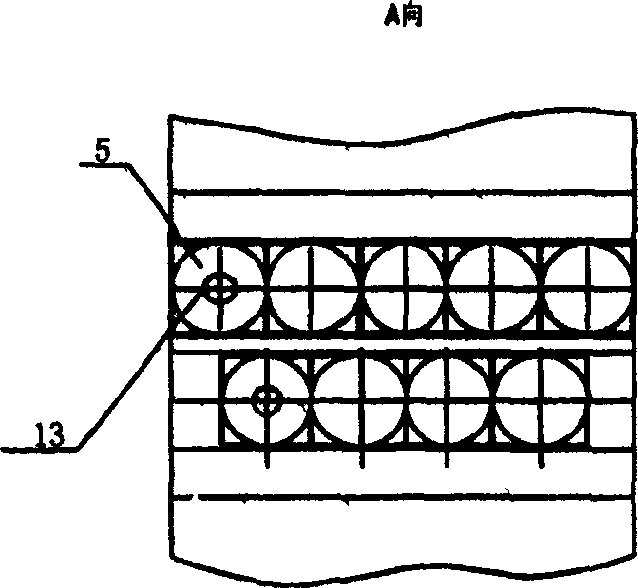

[0013] Depend on figure 1 It can be seen that the working process of the coal-water slurry layered combustion method of the present invention is as follows: the coal-water slurry is transported and poured into the slurry storage tank through the fuel delivery device, and is delivered to the slurry feeding system in front of the furnace by the slurry supply pump system, and the coal-water slurry is directly sent to the evaporation The forming device is the drying forming propeller 6, which uses the radiation temperature in the furnace to evaporate 50-60% of the water in the coal-water slurry, so that the coal-water slurry evaporates and dries to form a colloidal state, and then propels it through the drying and forming propeller 6. The screw drive device of the device 18 is layered and put into the moving combustion bed, that is, the chain row 11 in batches to continue to evaporate. During the continuous evaporation of water, part of the remaining water molecules in the coal slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com