Cleaning water discharge apparatus

A technology of spraying device and washing water, which is applied to water supply devices, indoor sanitary piping devices, sanitary equipment for toilets, etc., can solve problems such as inability to guarantee, speed up, and inability to guarantee a large amount of water saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach A-1

[0181] A First embodiment A-1 Structure of washing water spraying device

[0182] The washing water spouting device according to the first preferred embodiment of the present invention will be described below.

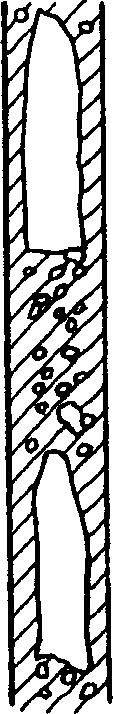

[0183] As shown in FIG. 5, the washing water spray device A according to the first preferred embodiment of the present invention includes: a washing water discharge nozzle 1; a pipe line 2 to form a washing water passage extending to the washing water discharge nozzle 1; and bubble mixing The mechanism 3 is arranged in the path of the pipeline 2; the forced air supply mechanism 4 is used to forcibly supply air to the air bubble mixing mechanism 3; and the continuous fluid valve 5 is arranged in the path of the pipeline 2 and the air bubble mixing mechanism 3 Upstream. The upstream end of the pipeline 2 is connected to a faucet not shown in FIG. 5.

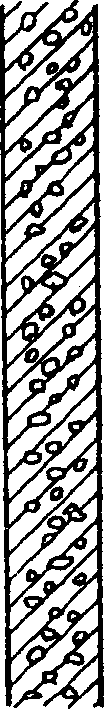

[0184] The bubble mixing mechanism 3 has a cylindrical bubble generating element 3a made of porous material. The cylindrical ...

no. 2 approach

[0226] Next, a washing water spray device according to a second embodiment of the present invention will be described.

[0227] As shown in FIG. 9, the washing water spraying device B according to the second preferred embodiment of the present invention includes: a washing water discharge nozzle 11; a pipe 12 to form a washing water passage extending to the washing water discharge nozzle 11; The mechanism 13 is arranged in the middle of the pipeline 12; the forced air supply mechanism 14 is used to forcibly supply air to the bubble mixing mechanism 13; and the washing water storage tank 15 is arranged on the upstream side of the pipeline 12.

[0228] The bubble mixing mechanism 13 has a cylindrical bubble generating element 13a made of a porous material. The cylindrical air bubble generating member 13a forms a part of the washing water channel. The cylindrical bubble generating element 13a has a large number of independent pores formed on its inner surface. The cross-sectional are...

no. 3 approach

[0246] Next, a washing water spray device according to a third embodiment of the present invention will be described.

[0247] The washing water spray device C is assembled in a washing system installed on a toilet bowl for washing various parts of the human body, such as anus and some hidden parts. As shown in Fig. 11, tap water enters the heat exchanger 31 through an electromagnetic shut-off valve 30 capable of controlling the water pressure. The heat exchanger 31 is equipped with: a heater 32; a first water level sensor 33 and a second water level sensor 34 for detecting the water level in the heat exchanger to prevent the heat exchanger 31 from heating up; and a temperature sensor 35 for monitoring The temperature of the water in the heat exchanger. The water heated to an appropriate temperature is led to the water passage selection valve 37 through the relief valve 36. The water passage selection valve 37 controls the water flow and selects the water passage for supplying wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com