Colour kinescope device

A color picture tube and tube-shaped technology, applied in the field of electrodes, can solve problems such as poor reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

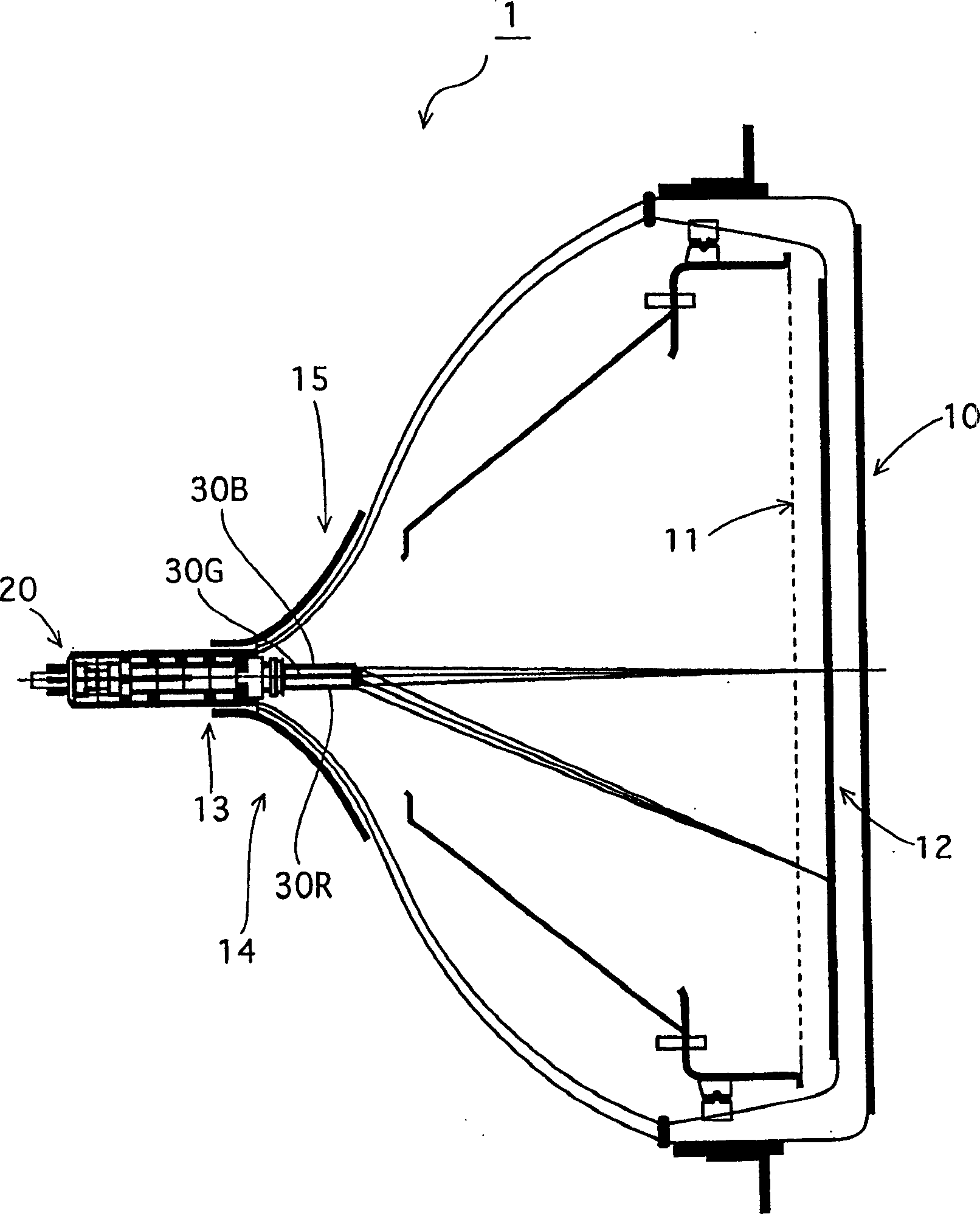

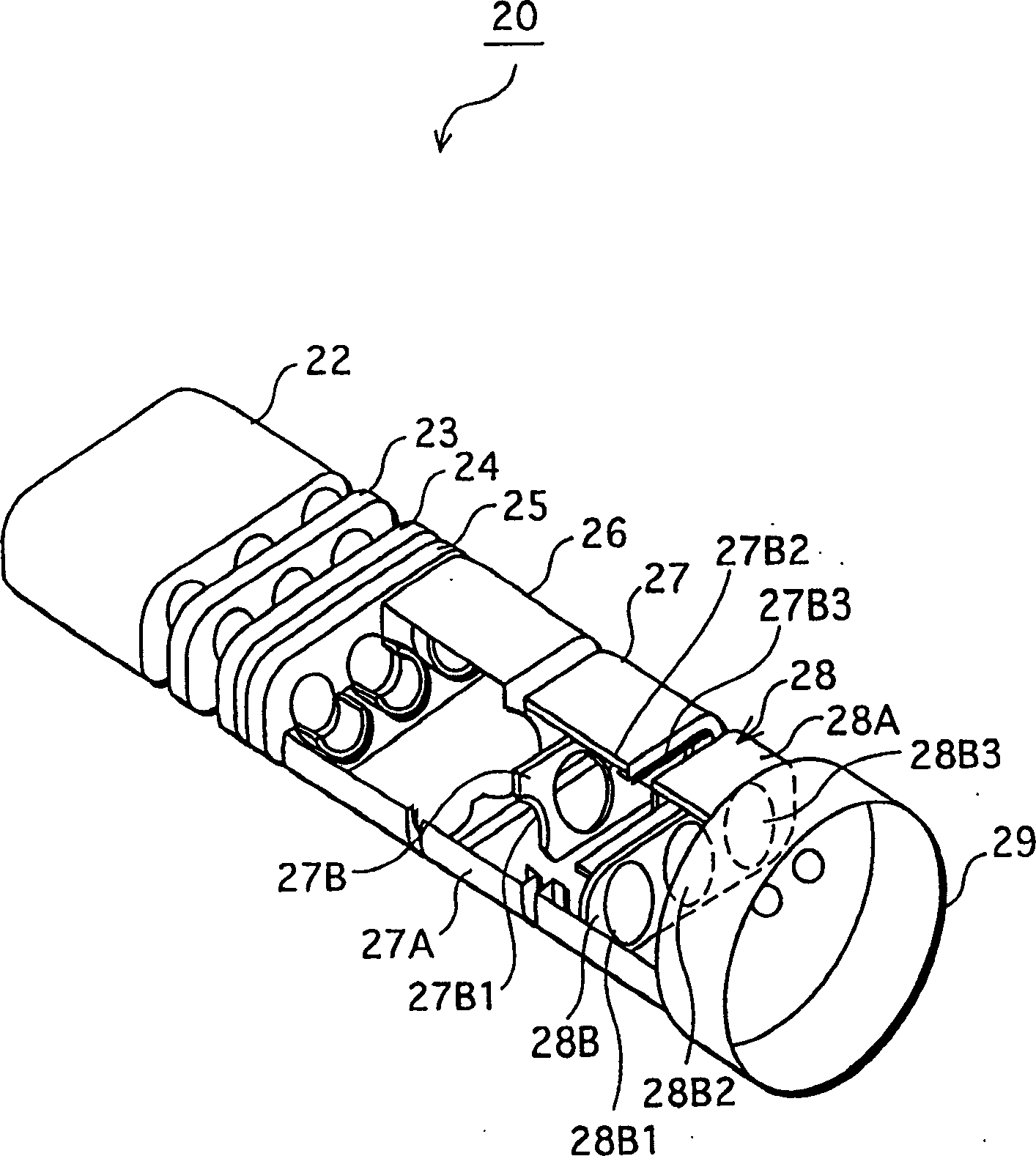

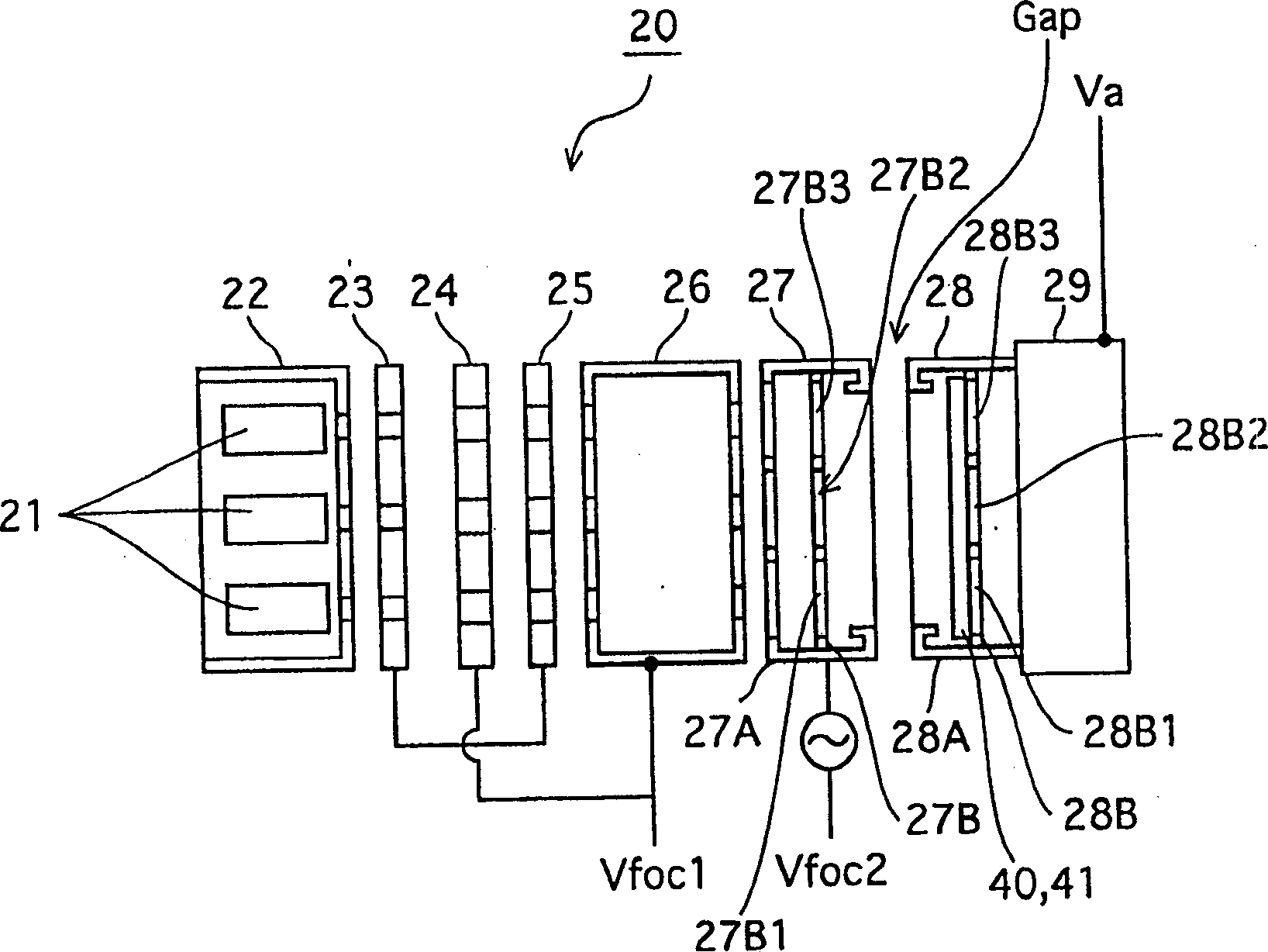

[0043] A color picture tube 1 according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0044] figure 1 is a cross-sectional view along the horizontal scanning direction, which shows the structure of the color picture tube 1 .

[0045]As shown in the figure, a color picture tube 1 is constituted by a picture tube 10 and a coaxial electron gun 20 . A picture tube 10 includes a screen 10 having R (red), G (green), B (blue) phosphors applied in a layered form on its inner side to face a shadow mask having a large number of The electron beams in it pass through the holes. The coaxial electron gun 20 is inserted from the base of the neck 13 of the kinescope 10 . Three electron beams 30R, 30G, 30B corresponding to RGB colors are emitted from the coaxial electron gun 20, and pass through the deflection magnetic field induced by the deflection yoke 15, which is along the widened portion 14 of the funnel and...

Embodiment 2

[0072] Embodiment 2 of the present invention will be described.

[0073] Figure 10 is a plan view showing the structure of the coaxial electron gun according to this embodiment, and Figure 11A and 11B The associated lens model is shown.

[0074] The difference from Embodiment 1 is that the ledge-shaped electrode plates 60 and 61 facing the gap between the focusing electrode 27 and the final accelerating electrode 28 are provided on the field correcting electrode plate 27B. and project toward the gap.

[0075] According to the structure, such as Figure 11A and 11B As shown, in addition to the lenses shown in FIG. 5 , quadrupole lenses 66, 67 and 68 are produced which have a greater divergence (concave lens) in the horizontal direction on the low pressure side than the main lens and a Greater focusing action than the main lens (convex lens).

[0076] Since these lenses allow the horizontal focusing effect to be weakened in the low pressure region, which is a region sig...

Embodiment 3

[0079] Embodiment 3 of the present invention will be described.

[0080] Figure 12 is a plan view showing the structure of a coaxial electron gun according to Embodiment 3 of the present invention.

[0081] In the coaxial electron gun of this embodiment, a protrusion 29A is formed on the shield cover of the electron gun of Embodiment 1 so as to protrude into the final accelerating electrode, and a base 29B of the protrusion 29A serves as a field correcting electrode plate. As described above, the flange-shaped electrode plates 40 and 41 are provided on this base portion 29B.

[0082] In addition to the above actions / effects, according to this structure, when the shield cover is fitted with the final accelerating electrode, the field correcting electrode plate can be disposed inside the final accelerating electrode, and thus the assembly of the electron gun is facilitated.

[0083] Here, although Embodiments 2 and 3 are implemented independently, they may be implemented in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com