Fast twisted steel cable connector

A steel hinge wire and connector technology, applied in the direction of transmission components or pulley ropes or cables, electrical components, textile cables, etc., can solve the problems of poor reliability, low efficiency, time-consuming, etc., and achieve improved swing, improved life and Reliability, ease of operation and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the embodiments of the drawings.

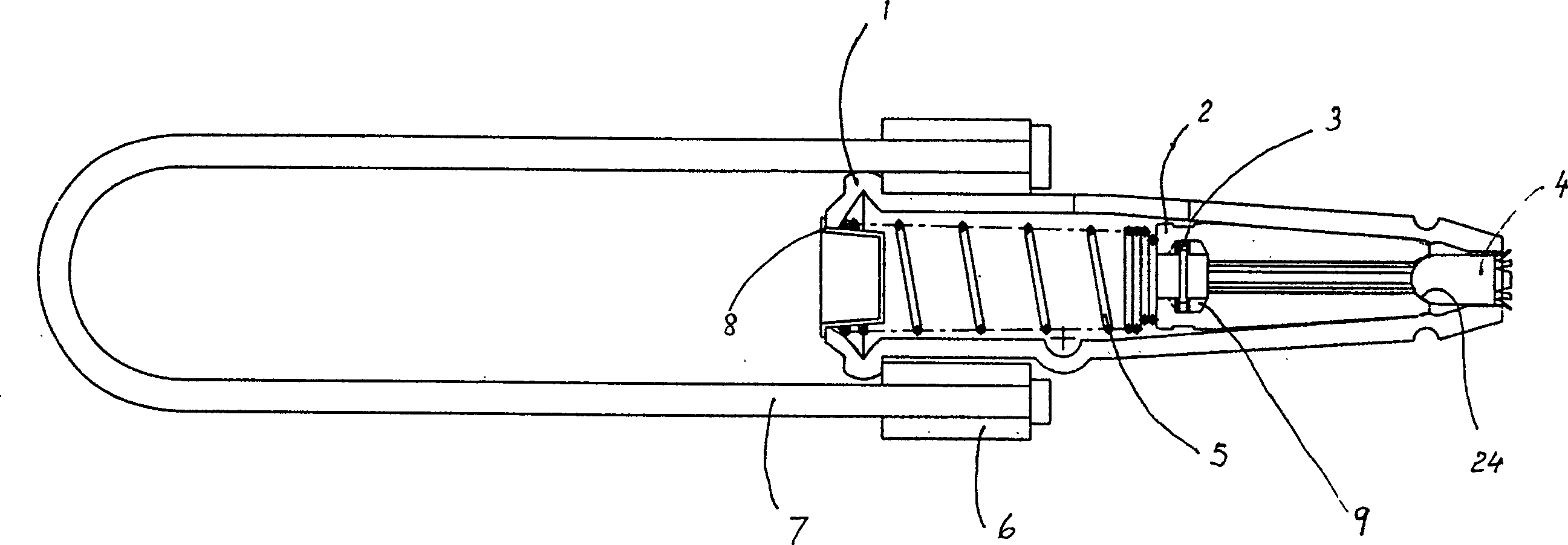

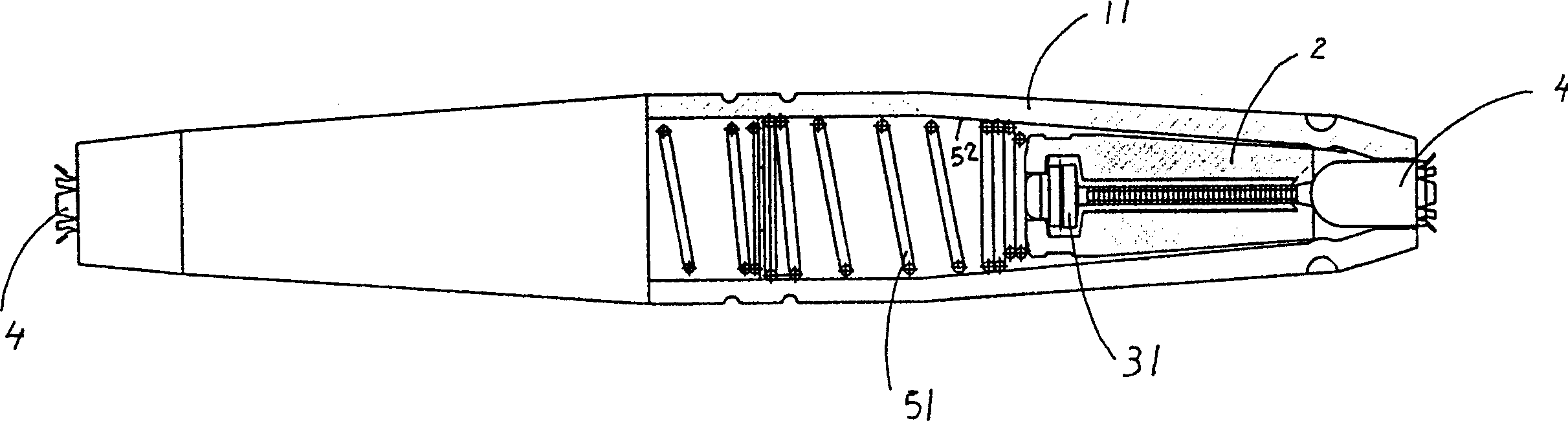

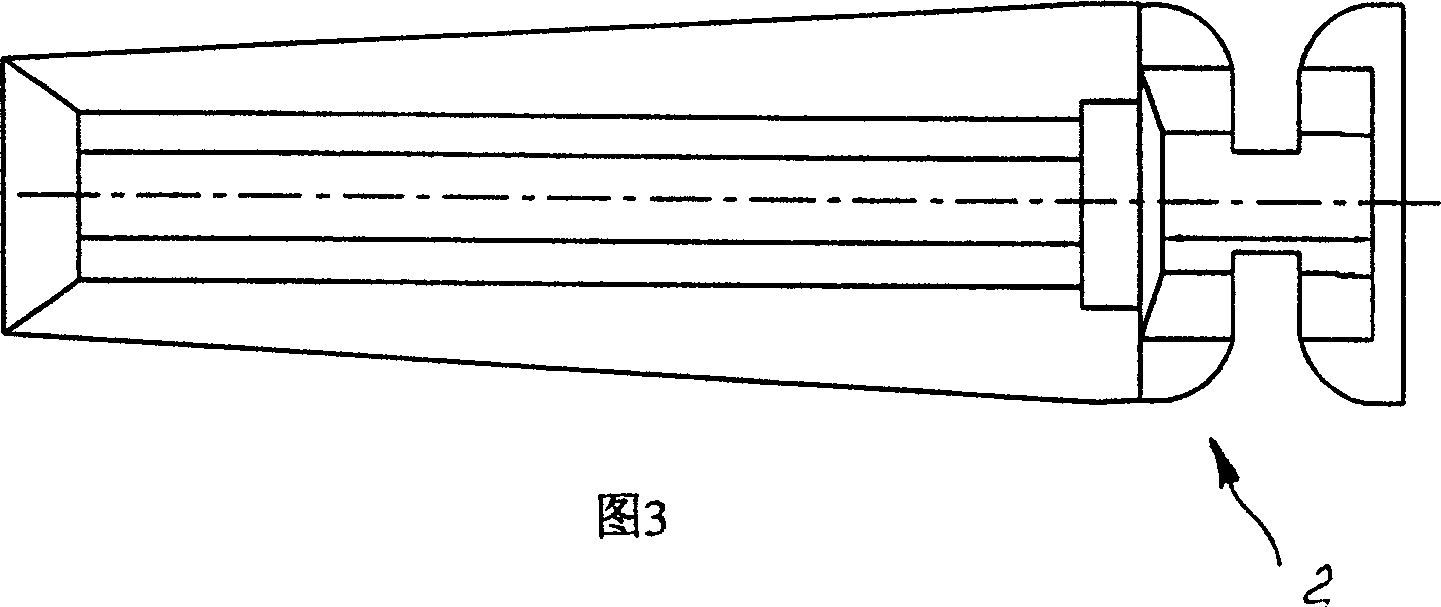

[0023] figure 1 , Figure 3 to Picture 9 The first embodiment of the present invention is shown: a single-head steel stranded wire quick connector. It includes a clamping jaw sleeve 1, a clamping jaw 2, and a pull rod 7; the appearance of the clamping jaw sleeve 1 is a half-shuttle-shaped, hollow shell, and an inner wall is provided at one end of the clamping jaw sleeve 1 Taper hole 52, the inner wall taper hole 52 is equipped with three tile-shaped clamping jaws 2 mutually forming 120° or four oblique cylindrical clamping jaws mutually forming 90°. A circle is provided at the rear of the clamping jaw 2. Annular inner cavity 9, in the annular inner cavity 9, a device is a clamping jaw seat 3 for positioning the clamping jaw 2 in the circumferential direction, in the cylindrical inner hole at the other end of the clamping jaw sleeve 1 Equipped with a spring 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com