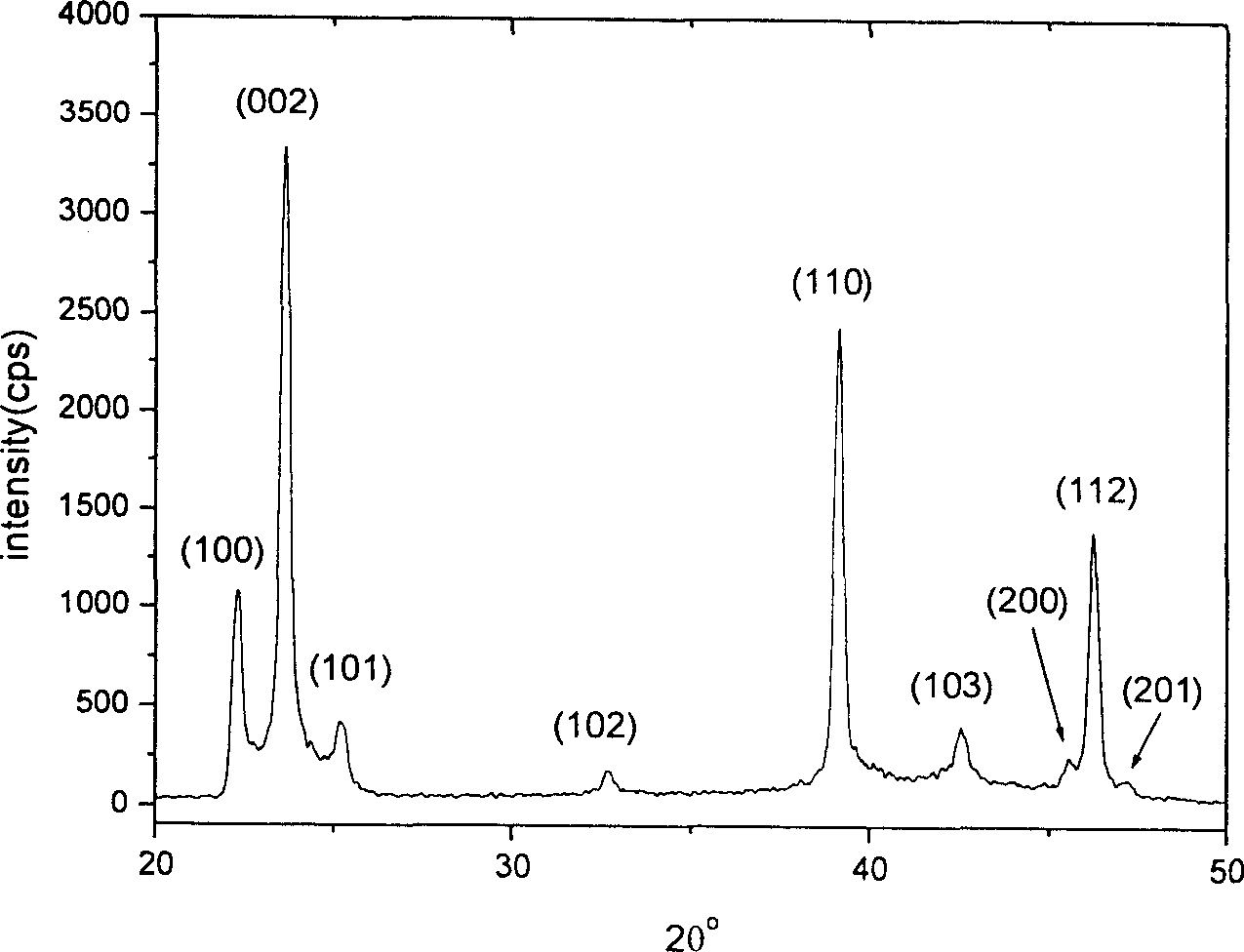

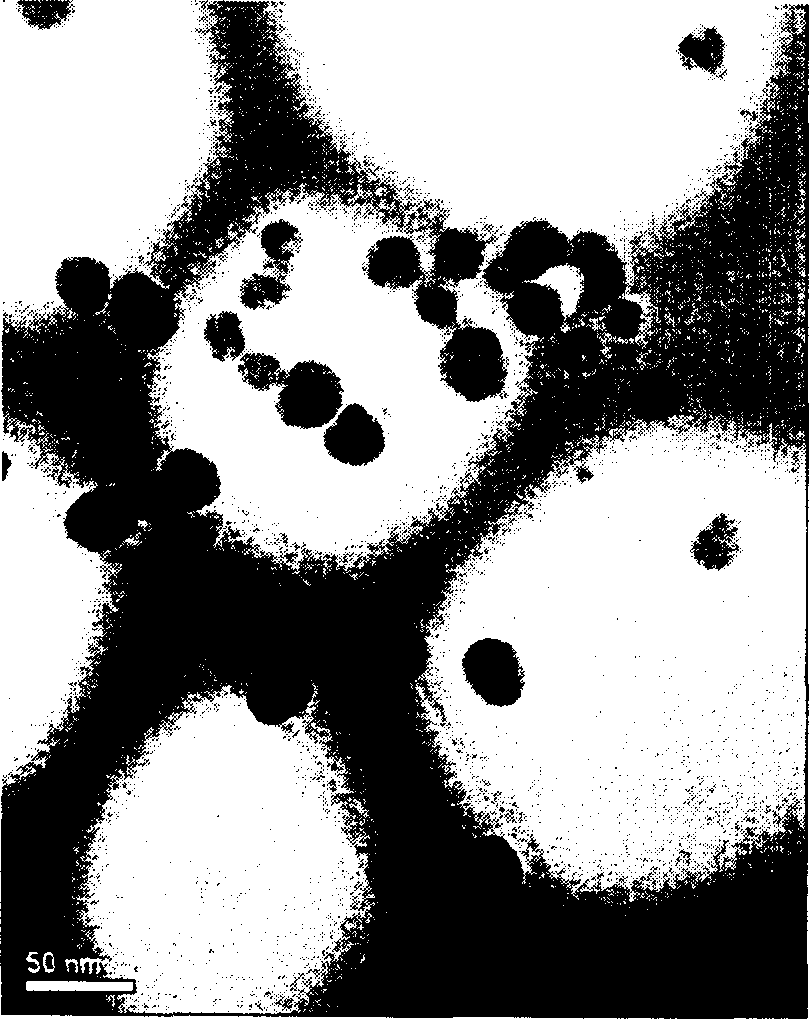

Prepn process of nano silver iodide powder

A nano-silver iodide and powder technology, which is applied in iodide preparation, nano-structure manufacturing, silver halide, etc., can solve problems such as complicated process technology, and achieve high purity, easy industrial scale production, and simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Nano silver iodide powder is prepared according to the following process steps.

[0019] a. Prepare the following two solutions respectively:

[0020] Silver nitrate clarified aqueous solution, containing in this solution: silver nitrate 0.1M / L, citric acid (complexing agent) 0.034M / L;

[0021] Potassium iodide clarified aqueous solution, which contains: potassium iodide 0.1M / L, citric acid (complexing agent) 0.034M / L, sodium dodecylsulfonate (dispersant) 0.01M / L;

[0022] B. at normal temperature, normal pressure, the silver nitrate clarified aqueous solution of above-mentioned preparation is slowly added dropwise in the potassium iodide clarified aqueous solution and fully stirs simultaneously, obtains nano-silver iodide precipitation after standing and settling;

[0023] c. The above nano-silver iodide precipitate is filtered, washed with water three times, and dried at 80-100° C. for 1-2.5 hours to obtain nano-silver iodide powder with a particle size of 15-30 nm. ...

Embodiment 2

[0033] Nano silver iodide powder is prepared according to the following process steps.

[0034] a. Prepare the following two solutions respectively:

[0035] Silver nitrate clarified aqueous solution, containing in this solution: silver nitrate 0.4M / L, citric acid (complexing agent) 0.136M / L;

[0036] Potassium iodide clarified aqueous solution, containing in this solution: Potassium iodide 0.4M / L, citric acid (complexing agent) 0.136M / L, sodium dodecylsulfonate (dispersant) 0.04M / L;

[0037] B. at normal temperature, normal pressure, the silver nitrate clarified aqueous solution of above-mentioned preparation is slowly added dropwise in the potassium iodide clarified aqueous solution and fully stirs simultaneously, obtains nano-silver iodide precipitation after standing and settling;

[0038] c. The above nano-silver iodide precipitate is filtered, washed with water three times, and dried at 80-100° C. for 1-2.5 hours to obtain nano-silver iodide powder with a particle size ...

Embodiment 3

[0040] Nano silver iodide powder is prepared according to the following process steps.

[0041] a. Prepare the following two solutions respectively:

[0042] Silver nitrate clear aqueous solution, containing in this solution: silver nitrate 0.25M / L, citric acid (complexing agent) 0.085M / L;

[0043] Potassium iodide clarified aqueous solution contains: potassium iodide 0.25M / L, citric acid (complexing agent) 0.085M / L, sodium dodecylsulfonate (dispersant) 0.025M / L;

[0044] B. at normal temperature, normal pressure, the silver nitrate clarified aqueous solution of above-mentioned preparation is slowly added dropwise in the potassium iodide clarified aqueous solution and fully stirs simultaneously, obtains nano-silver iodide precipitation after standing and settling;

[0045] c. The above nano-silver iodide precipitate is filtered, washed with water three times, and dried at a temperature of 80-100° C. for 1-2.5 hours to obtain nano-silver iodide powder with a particle size of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com