Optical character lens made of photochromatic composite plastics or semi-finished product blank

A technology of optical properties and composite plastics, applied in the direction of optical components, optical components, optics, etc., can solve the problems of expensive, time-consuming, large investment in storage and transportation devices, etc., and achieve the effect of fast and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

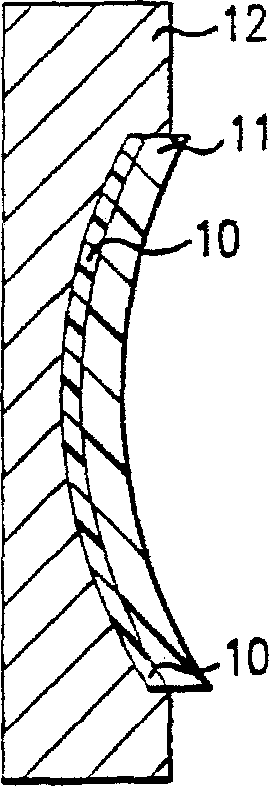

[0087] A semi-finished blank was formed from the following liquid resin formulation: Diallyl Carbonate (CR-39), 88.5% (W / V); Diisopropyl Percarbonate (IPP), 2.5% and Methyl Methacrylate (MMA), 8%. The liquid resin was injected into a mold cavity consisting of a spherical front mold with a radius of curvature of 92 mm, a rear mold with a diameter of 78 mm, and a polyvinyl chloride gasket. The mold assembly was cured in a temperature-controlled oven ramped from 100°F to 170°F over a 16-hour period. After demoulding, the blank was annealed at 185°F for 2 hours. The semi-finished blank was then trimmed to 74mm.

[0088] The following mixtures were used to formulate casting resins: diallyl carbonate (CR-39), 75%; ethoxylated trihydroxypropane triacrylate, 10%; polyethylene glycol (molecular weight 400) diacrylate, 12 % and Durcure 1173, 3%. 0.05 ml of the casting resin was injected into a spherical mold with a radius of curvature of 89.5 mm made of crown glass. Three strips of ...

Embodiment 2

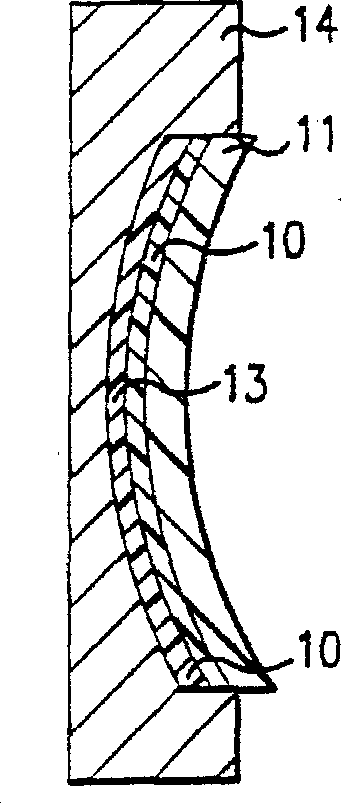

[0090] A single-focus lens with a spherical magnification of -2.50D and a cylindrical magnification of -1.50D is made of bisphenol A polycarbonate by injection molding. The convex curvature of the single vision lens is 5.75D. The casting resin formulation was as follows: diallyl carbonate monomer (CR-307 available from PPG), 75% (w / v); polyethylene glycol diacrylate (SR 344 available from Sartomer), 11.7%; A naphthalene spirooxazine photochromic additive (PPG 1072), 0.3%; and Durcure 1173 (available from Ciba Geigy), 3%. 0.60 ml of the above casting resin was injected into a spherical glass mold made of crown glass with a concave curvature of 5.70D. Place the above-mentioned single vision lens on the resin so that the resin layer expands outward. The mold assembly is cured under UV radiation and the modified single vision lens coated with the photochromic material is either given to the patient or sent to a second casting process where the convex surface with an additional a...

Embodiment 3

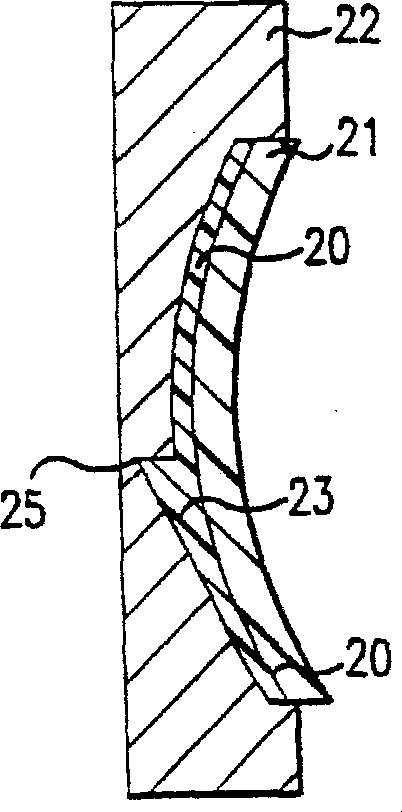

[0092] Prepare a mold made of crown glass, whose concave surface curvature is 4.16D, prepare the first photopolymerizable resin layer according to the following formula: CR-307 (65%); SR-344 (25%); a naphthalene spiro Oxazine photochromic additive (PPG 1072) (0.7%) and Irgacure 184 from Ciba Geigy (3%). The photopolymerizable resin is sprayed on the concave surface of the mold to form a uniform thin layer, and then irradiated with ultraviolet light for a short time (about 2 seconds) to make the coating reach the gel point and prevent its flow. The second photopolymerizable resin was formulated as follows: CR-39 (75%); di-trimethylolpropane triacrylate (SR-355, produced by Sartomer) (8%); alkoxylated aliphatic Diacrylate (SR 9209 from Sartomer) (9%); dipentaerythritol pentaacrylate (SR 399 from Sartomer), (33%) and Durcure 1173 (3%). 0.50ml of photopolymerization resin is added to the above mold, and a single-focus lens is placed on the added resin layer, so that the resin lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com