Suction nozzle of vacuum cleaner

A technology for vacuum cleaners and nozzle heads, which is applied in the direction of suction nozzles, and can solve the problems of impossible suction work and power consumption of suction nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

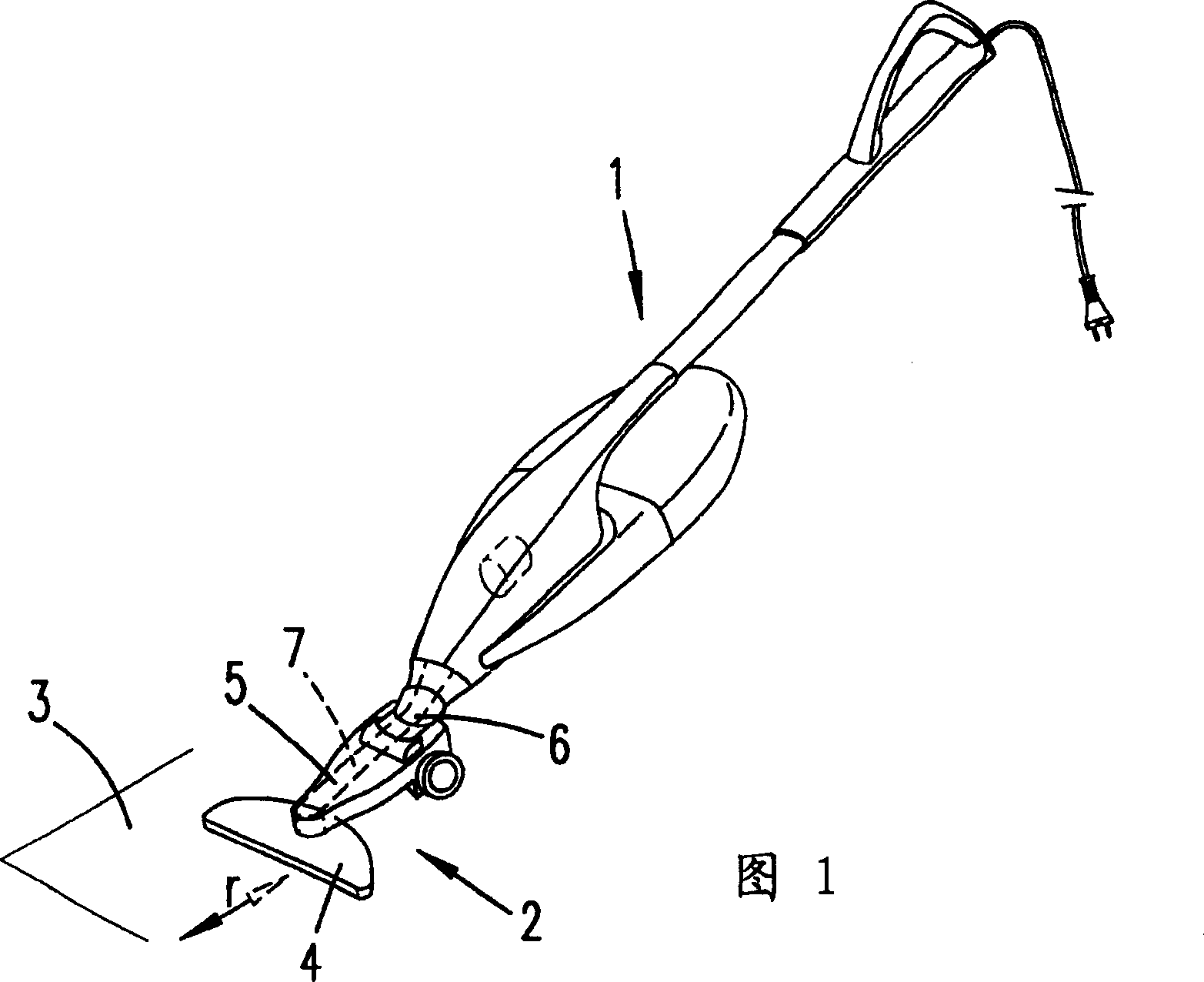

[0039] Firstly, a vacuum cleaner 1 with a suction nozzle 2 for treating a floor 3 is depicted and described with reference to FIG. 1 . In the illustrated embodiment the nozzle 2 is a hard floor nozzle. However, the features of the suction nozzle 2 described below are also conceivable with rotating suction nozzles for cleaning carpets.

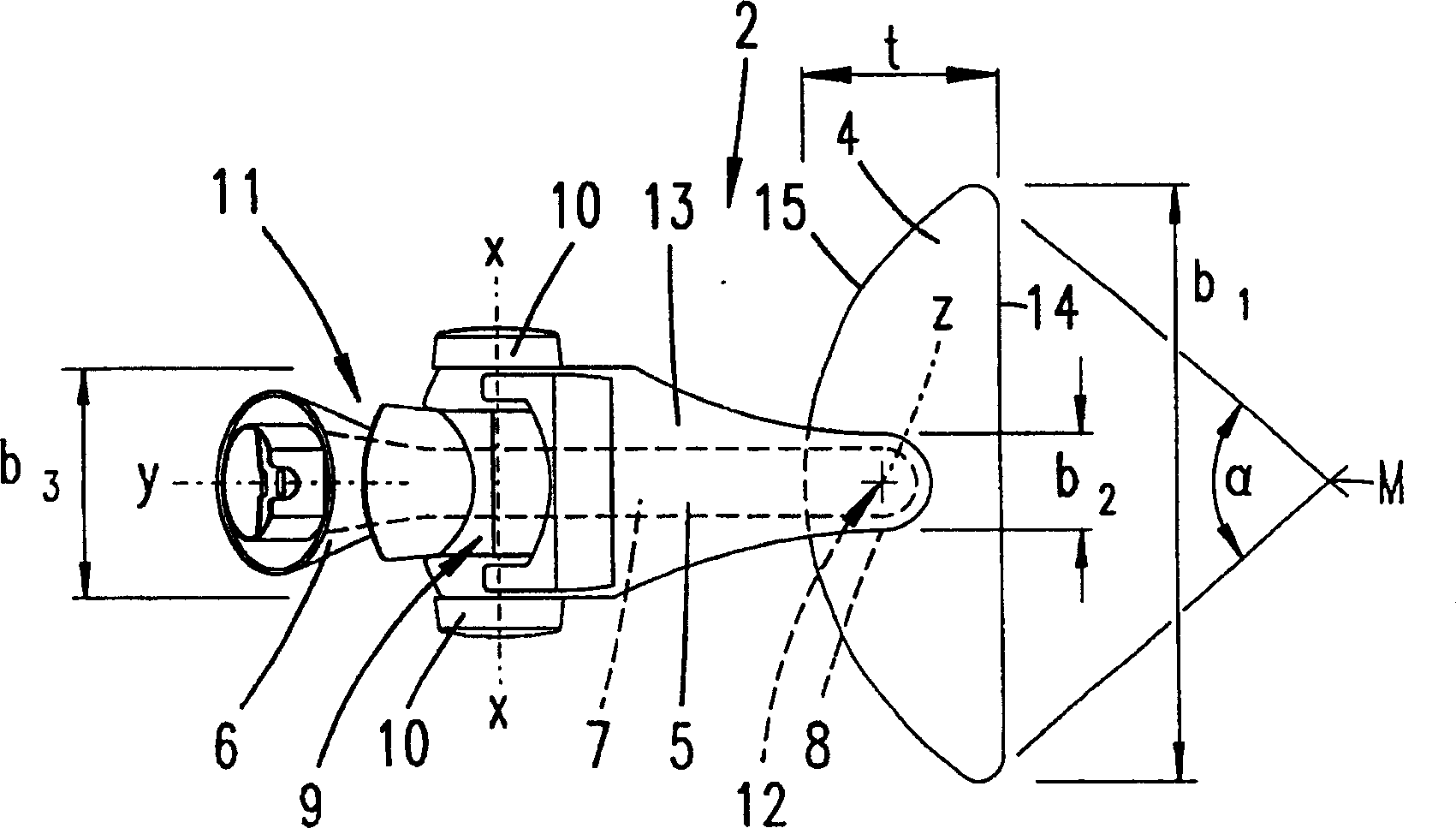

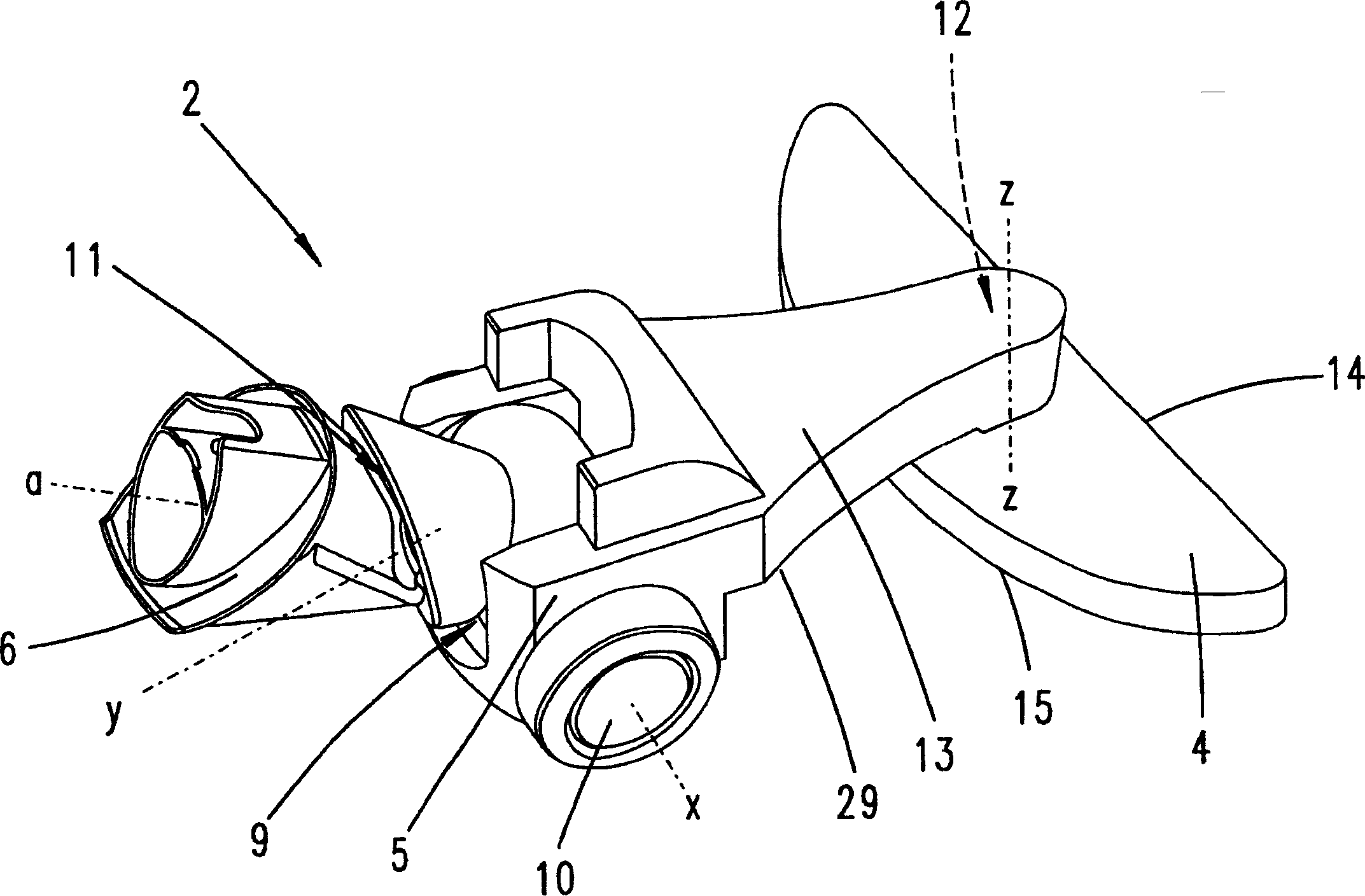

[0040] The suction nozzle 2 basically consists of a nozzle head 4 placed on the ground 3 and a nozzle body 5 connecting the nozzle head 4 with the vacuum cleaner 1, wherein a connecting pipe 6 is constructed on the nozzle body 5 so that the suction The mouth 2 is connected to the vacuum cleaner 1 . From the connecting pipe 6 a suction channel 7 extends through the nozzle body 5 , which opens into the nozzle tip 4 . The suction opening is marked with reference numeral 8 in the figure.

[0041] The connecting pipe 6 is arranged in the upper side of an end region of the nozzle body 5 such that the connecting pipe 6 is pivotable in a first swive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com