Variable orifice flow sensor

A flow sensor, variable technology, applied in the direction of sensor, non-electric variable control, liquid/fluid solid measurement, etc., can solve the problems of hardness or stiffness loss, responsiveness loss, flap stiffness loss, etc., to increase service life, Good resolution, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Detailed description of the preferred embodiment

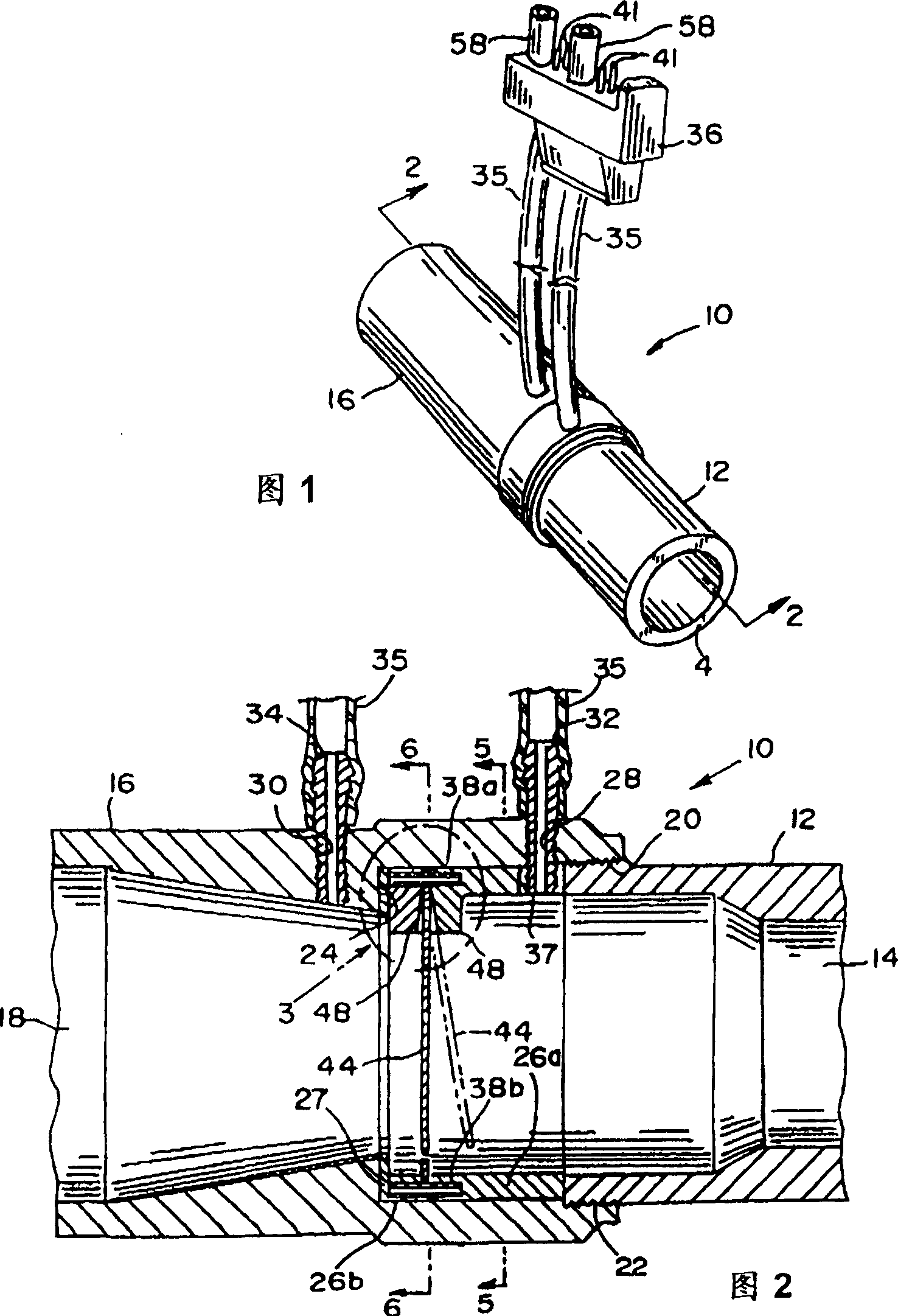

[0022] Referring now to Figures 1 through 8, there is shown a variable orifice fluid flow sensor 10 according to a preferred embodiment of the present invention. As best shown in FIGS. 1 and 2 , the sensor 10 includes a first tube 12 defining a first fluid flow orifice 14 and a second tube 16 defining a second fluid flow orifice 18 . The second tube 16 has an internally threaded opening 20 opposite the second fluid flow aperture 18 that receives the externally threaded end 22 of the first tube 12 . Thus, the first and second tubular members 12, 16 are detachably coupled to each other by the mating threads of the threaded opening 20 and the threaded end 22. Because the sensor 10 is a bi-directional sensor, each fluid flow port 14, 18 can be used either as an input port or as an output port.

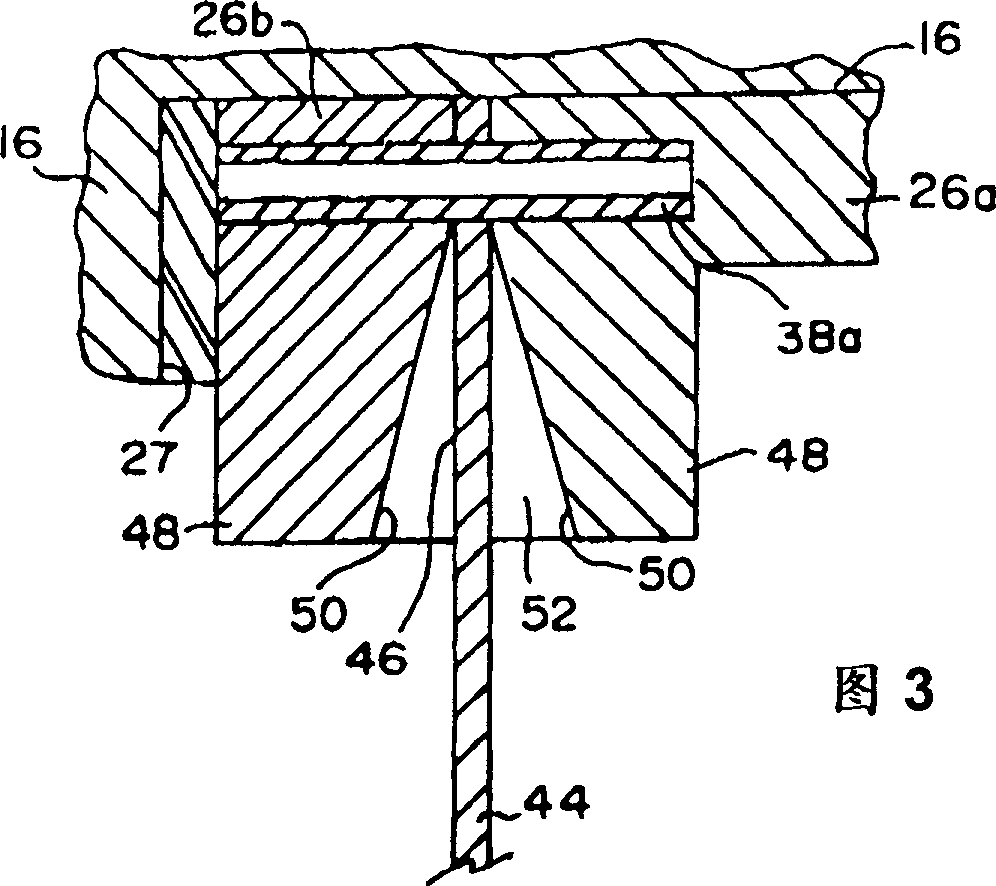

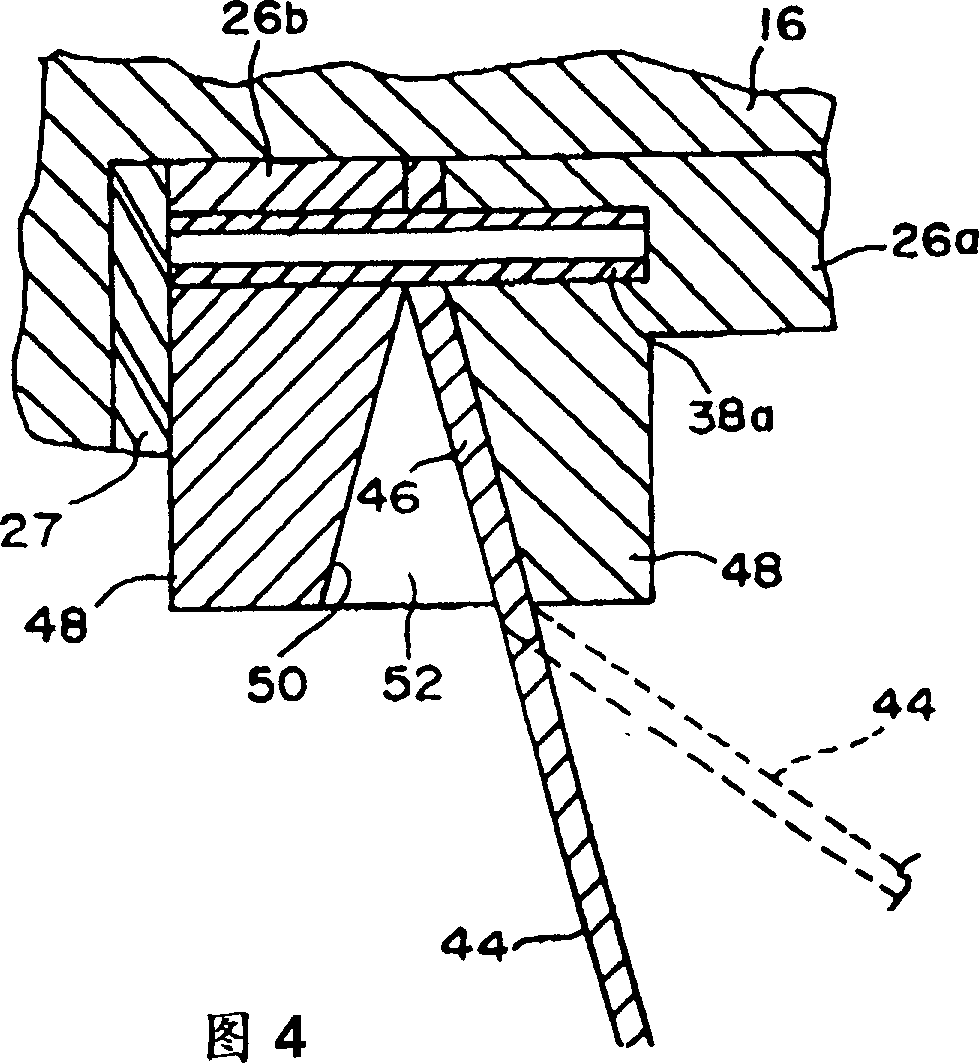

[0023] An annular shoulder 24 is located inside the second tubular member 16 and extends inwardly from the threaded opening 20 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com